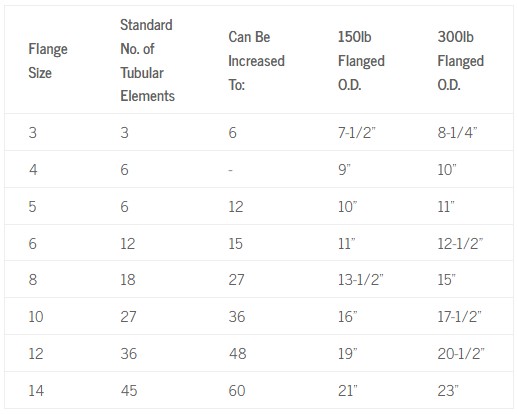

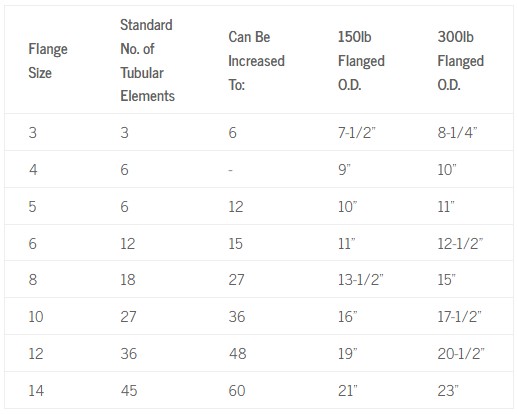

8″ – 150# FLANGED IMMERSION HEATERS STANDARD SIZES

<–6″ – 150 # FLANGED IMMERSION HEATERS STANDARD SIZES

10″ – 150# FLANGED IMMERSION HEATERS STANDARD SIZES ->

<–6″ – 150 # FLANGED IMMERSION HEATERS STANDARD SIZES

10″ – 150# FLANGED IMMERSION HEATERS STANDARD SIZES ->