Infrared Radiant Heaters

Quartz Infrared Heaters are used when you need to apply precise heat radiation with infinite controllability, infrared heating technology is the best option.

Quartz Infrared Heater lamp is an example of efficiently utilizing the heat output of a specialty halogen lamp. Most of the output from this light source falls in the infrared region, and it is proven to be an extremely efficient heat energy source.

Ushio Quartz Infrared Heater lamp creates clean, safe heat source which can be flexibly controlled and minimizes footprint to maximize design possibilities.

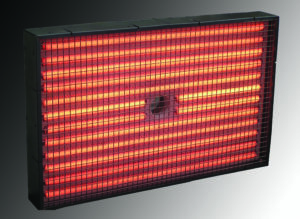

Flat panel infrared radiant heaters are sleek and modern heating devices designed to efficiently emit infrared radiation for targeted heat. These heaters consist of thin, flat panels typically made from materials like carbon fiber, quartz, or ceramic that generate and emit infrared heat when electricity passes through them.

Characterized by their slim profile and versatile design, flat panel infrared radiant heaters are often wall-mounted or can be freestanding, allowing for easy installation and flexible placement in various spaces. They work by emitting infrared rays that directly heat up objects within their range without significantly warming the air, creating a comfortable and gentle warmth similar to the sun’s rays.

Ceramic Infrared Heater is a type of heating device that utilizes ceramic elements to produce and emit infrared radiation, which transfers heat directly to objects and people in its path. These heaters typically consist of a ceramic plate or coils that heat up when electricity passes through them. They emit infrared rays that warm up nearby objects by penetrating the air without actually heating it directly, making them an efficient and quick heating solution. Ceramic infrared heaters are known for their energy efficiency, rapid heating capabilities, and ability to provide focused warmth in specific areas.

![CeramicInfraredRadiantPanel[1] Ceramic Infrared Panel](https://sethermal.com/wp-content/uploads/2018/05/Ceramic20Infrared20Radiant20Panel1-1.jpg)