Flexible Tubular Heating Elements

Flexible tubular heating elements are engineered to deliver consistent, reliable heat in applications where traditional heaters can’t conform. Designed to bend and shape around complex surfaces, these elements provide even temperature distribution and exceptional thermal control — all while maintaining durability in demanding environments.

Perfect for industrial machinery, medical devices, food processing, and packaging systems, flexible tubular heaters offer customizable watt densities, diameters, and lengths to match your exact design needs. Their robust construction ensures long service life, reduced maintenance, and superior energy efficiency.

Key Benefits

-

Bendable design for tight spaces and complex geometries

-

Uniform heating for improved process control and product quality

-

Fast heat response with efficient energy transfer

-

Durable construction for high-performance and long-term reliability

-

Custom configurations to fit unique applications

Whether you’re improving an existing design or developing a new system, flexible tubular heating elements give you the freedom to heat precisely where it’s needed most.

User-formable, heavy-duty design: the heater uses a flexible solid casing that remains seated in the groove, yet is easy to install.

Optimised durability: manufactured with an inner layer of highly compressed copper powder, contributing to increased durability while maintaining flexibility.

Marked at the center and cold sections: clear visual indicators for installation.

Made in the U.S. and available for next-day shipping in standard straight lengths.

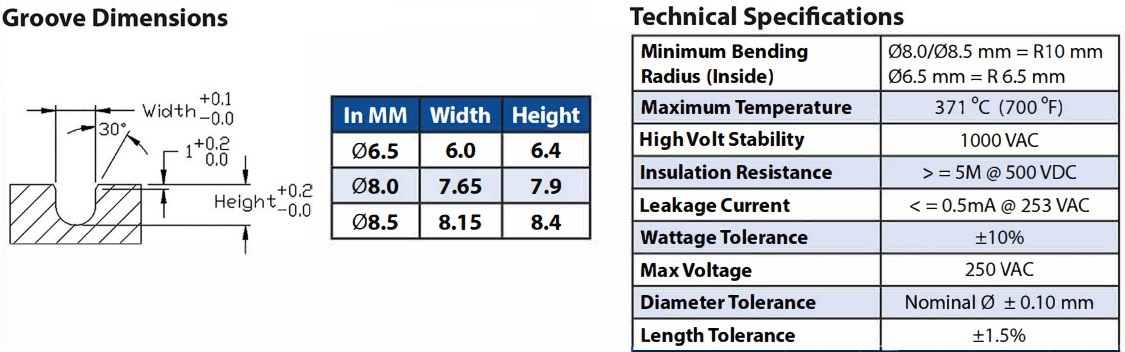

Technical Specifications:

-

-

Maximum temperature up to 371 °C (700 °F) in standard diameters.

- Minimum Bending Radius (Inside) ⌀ 8.0 / ⌀ 8.5 mm = R10 mm, ⌀ 6.5 mm = R6.5 mm

-

High voltage stability: 1000 VAC,

-

Insulation resistance ≥ 50 MΩ @ 500 VDC.

-

Leakage current ≤ 0.5 mA @ 253 VAC.

-

Wattage tolerance ±10%.

- Max Voltage 250 VAC

- Diameter Tolerance Nominal ⌀ ± 0.10mm

- Length Tolerance ±1.5%

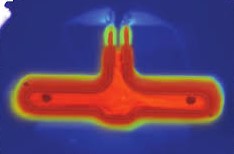

Thermal image demonstrating the heating efficiency of the flex tubular heater placed within a manifold.

-

Connectors

SCREW TERMINAL (STANDARD)

PLUG N HEAT CERAMIC INSULATIED

LEAD WIRE ADAPTER KIT

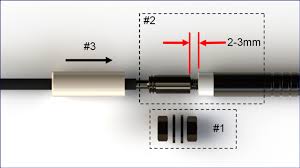

The Lead Adapter Kit is an optional add-on designed for Ø8.0 mm and Ø8.5 mm flexible tubular heating elements. It provides a safe, high-temperature connection for a 1,000 mm (40″) lead wire and can be reused for servicing or maintenance. Each kit is designed for one heater, with extended lead wire lengths available upon request.

Key Features

-

Secure, high-temperature electrical connection

-

Reusable design for long-term serviceability

-

Compatible with Ø8.0 mm and Ø8.5 mm flexible tubular heating elements

-

Standard 1,000 mm (40″) lead length; custom options available

AVAILABLE SIZES

| Part Number | Length (mm) | Heated Length (mm) | Wattage | Availability | Voltage |

| 65R-0300 | 300 | 240 | 350 W | Build | 230V |

| 65R-0350 | 350 | 290 | 400 W | Build | 230V |

| 65R-0400 | 400 | 340 | 500 W | Stock | 230V |

| 65R-0450 | 450 | 390 | 600 W | Stock | 230V |

| 65R-0500 | 500 | 440 | 650 W | Stock | 230V |

| 65R-0550 | 550 | 490 | 700 W | Stock | 230V |

| 65R-0600 | 600 | 540 | 800 W | Stock | 230V |

| 65R-0650 | 650 | 590 | 850 W | Stock | 230V |

| 65R-0700 | 700 | 640 | 900 W | Stock | 230V |

| 65R-0750 | 750 | 690 | 1000 W | Stock | 230V |

| 65R-0800 | 800 | 740 | 1100 W | Stock | 230V |

| 65R-0850 | 850 | 790 | 1200 W | Build | 230V |

| 65R-0900 | 900 | 840 | 1300 W | Build | 230V |

| 65R-0950 | 950 | 890 | 1350 W | Build | 230V |

| 65R-1000 | 1000 | 940 | 1400 W | Build | 230V |

| 65R-1050 | 1050 | 990 | 1450 W | Build | 230V |

| 65R-1100 | 1100 | 1040 | 1500 W | Build | 230V |

| 65R-1150 | 1150 | 1090 | 1550 W | Build | 230V |

| 65R-1200 | 1200 | 1140 | 1600 W | Build | 230V |

| 65R-1250 | 1250 | 1190 | 1650 W | Build | 230V |

| 65R-1300 | 1300 | 1240 | 1700 W | Build | 230V |

| 65R-1350 | 1350 | 1290 | 1800 W | Build | 230V |

| 65R-1400 | 1400 | 1340 | 1900 W | Build | 230V |

| 65R-1450 | 1450 | 1390 | 2000 W | Build | 230V |

| 65R-1500 | 1500 | 1440 | 2100 W | Build | 230V |

| Part Number | Length (mm) | Heated Length (mm) | Wattage | Availability | Voltage |

| 80R-0300 | 300 | 240 | 560 W | Stock | 240V |

| 80R-0350 | 350 | 290 | 675 W | Stock | 240V |

| 80R-0400 | 400 | 340 | 795 W | Stock | 240V |

| 80R-0425 | 425 | 365 | 850 W | Stock | 240V |

| 80R-0450 | 450 | 390 | 910 W | Stock | 240V |

| 80R-0475 | 475 | 415 | 970 W | Stock | 240V |

| 80R-0500 | 500 | 240 | 1025 W | Stock | 240V |

| 80R-0525 | 525 | 465 | 1090 W | Stock | 240V |

| 80R-0550 | 550 | 490 | 1145 W | Stock | 240V |

| 80R-0575 | 575 | 515 | 1200 W | Stock | 240V |

| 80R-0600 | 600 | 540 | 1260 W | Stock | 240V |

| 80R-0625 | 625 | 565 | 1320 W | Stock | 240V |

| 80R-0650 | 650 | 590 | 1380 W | Stock | 240V |

| 80R-0675 | 675 | 615 | 1440 W | Stock | 240V |

| 80R-0700 | 700 | 640 | 1495 W | Stock | 240V |

| 80R-0725 | 725 | 665 | 1550 W | Stock | 240V |

| 80R-0750 | 750 | 690 | 1615 W | Stock | 240V |

| 80R-0775 | 775 | 715 | 1670 W | Stock | 240V |

| 80R-0800 | 800 | 740 | 1730 W | Stock | 240V |

| 80R-0850 | 850 | 790 | 1845 W | Stock | 240V |

| 80R-0900 | 900 | 840 | 1960 W | Stock | 240V |

| 80R-0950 | 950 | 890 | 2080 W | Stock | 240V |

| 80R-1000 | 1000 | 940 | 2195 W | Stock | 240V |

| 80R-1050 | 1050 | 990 | 2315 W | Stock | 240V |

| 80R-1100 | 1100 | 1040 | 2430 W | Stock | 240V |

| 80R-1150 | 1150 | 1090 | 2545 W | Stock | 240V |

| 80R-1200 | 1200 | 1140 | 2665 W | Stock | 240V |

| 80R-1250 | 1250 | 1190 | 2780 W | Stock | 240V |

| 80R-1300 | 1300 | 1240 | 2895 W | Stock | 240V |

| 80R-1350 | 1350 | 1290 | 3015 W | Stock | 240V |

| 80R-1400 | 1400 | 1340 | 3130 W | Stock | 240V |

| 80R-1450 | 1450 | 1390 | 3245 W | Stock | 240V |

| Part Number | Length (mm) | Heated Length (mm) | Wattage (W) | Availability | Voltage |

| 85R-0300 | 300 | 240 | 650 | Build | 230V |

| 85R-0350 | 350 | 290 | 750 | Build | 230V |

| 85R-0400 | 400 | 340 | 795 | Build | 230V |

| 85R-0425 | 425 | 365 | 975 | Build | 230V |

| 85R-0450 | 450 | 390 | 1050 | Build | 230V |

| 85R-0475 | 475 | 415 | 1100 | Build | 230V |

| 85R-0500 | 500 | 240 | 1150 | Stock | 230V |

| 85R-0525 | 525 | 465 | 1225 | Stock | 230V |

| 85R-0550 | 550 | 490 | 1300 | Stock | 230V |

| 85R-0575 | 575 | 515 | 1375 | Stock | 230V |

| 85R-0600 | 600 | 540 | 1450 | Stock | 230V |

| 85R-0625 | 625 | 565 | 1525 | Stock | 230V |

| 85R-0650 | 650 | 590 | 1600 | Stock | 230V |

| 85R-0675 | 675 | 615 | 1675 | Build | 230V |

| 85R-0700 | 700 | 640 | 1750 | Stock | 230V |

| 85R-0725 | 725 | 665 | 1825 | Build | 230V |

| 85R-0750 | 750 | 690 | 1900 | Stock | 230V |

| 85R-0775 | 775 | 715 | 1975 | Build | 230V |

| 85R-0800 | 800 | 740 | 2050 | Stock | 230V |

| 85R-0850 | 850 | 790 | 2200 | Stock | 230V |

| 85R-0900 | 900 | 840 | 2350 | Stock | 230V |

| 85R-0950 | 950 | 890 | 2500 | Stock | 230V |

| 85R-1000 | 1000 | 940 | 2650 | Stock | 230V |

| 85R-1050 | 1050 | 990 | 2800 | Stock | 230V |

| 85R-1100 | 1100 | 1040 | 2930 | Stock | 230V |

| 85R-1150 | 1150 | 1090 | 3060 | Stock | 230V |

| 85R-1200 | 1200 | 1140 | 3190 | Stock | 230V |

| 85R-1250 | 1250 | 1190 | 3320 | Stock | 230V |

| 85R-1300 | 1300 | 1240 | 3450 | Stock | 230V |

| 85R-1350 | 1350 | 1290 | 3580 | Stock | 230V |

| 85R-1400 | 1400 | 1340 | 3600 | Stock | 230V |

| 85R-1450 | 1450 | 1390 | 3600 | Stock | 230V |

| 85R-1500 | 1500 | 1240 | 3600 | Stock | 230V |

| Part Number | Length (mm) | Heated Length (mm) | Wattage (W) | Availability | Voltage |

| 60SQ-0300 | 300 | 240 | 350 | Build | 230V |

| 60SQ-0350 | 350 | 290 | 400 | Build | 230V |

| 60SQ-0400 | 400 | 340 | 500 | Stock | 230V |

| 60SQ-0450 | 450 | 390 | 600 | Stock | 230V |

| 60SQ-0500 | 500 | 440 | 650 | Stock | 230V |

| 60SQ-0550 | 550 | 490 | 700 | Stock | 230V |

| 60SQ-0600 | 600 | 540 | 800 | Stock | 230V |

| 60SQ-0650 | 650 | 590 | 850 | Stock | 230V |

| 60SQ-0700 | 700 | 640 | 900 | Stock | 230V |

| 60SQ-0750 | 750 | 690 | 1000 | Stock | 230V |

| 60SQ-0800 | 800 | 740 | 1100 | Stock | 230V |

| 60SQ-0850 | 850 | 790 | 1200 | Build | 230V |

| 60SQ-0900 | 900 | 840 | 1300 | Build | 230V |

| 60SQ-0950 | 950 | 890 | 1350 | Build | 230V |

| 60SQ-1000 | 1000 | 940 | 1400 | Build | 230V |

| 60SQ-1050 | 1050 | 990 | 1450 | Build | 230V |

| 60SQ-1100 | 1100 | 1040 | 1500 | Build | 230V |

| 60SQ-1150 | 1150 | 1090 | 1550 | Build | 230V |

| 60SQ-1200 | 1200 | 1140 | 1600 | Build | 230V |

| 60SQ-1250 | 1250 | 1190 | 1650 | Build | 230V |

| 60SQ-1300 | 1300 | 1240 | 1700 | Build | 230V |

| 60SQ-1350 | 1350 | 1290 | 1800 | Build | 230V |

| 60SQ-1400 | 1400 | 1340 | 1900 | Build | 230V |

| 60SQ-1450 | 1450 | 1390 | 2000 | Build | 230V |

| 60SQ-1500 | 1500 | 1440 | 2100 | Build | 230V |

| Part Number | Length (mm) | Heated Length (mm) | Wattage (W) | Availability | Voltage |

| 80SQ-0300 | 300 | 240 | 650 | Build | 230V |

| 80SQ-0350 | 350 | 290 | 750 | Build | 230V |

| 80SQ-0400 | 400 | 340 | 795 | Build | 230V |

| 80SQ-0425 | 425 | 365 | 975 | Build | 230V |

| 80SQ-0450 | 450 | 390 | 1050 | Build | 230V |

| 80SQ-0475 | 475 | 415 | 1100 | Build | 230V |

| 80SQ-0500 | 500 | 240 | 1150 | Stock | 230V |

| 80SQ-0525 | 525 | 465 | 1225 | Stock | 230V |

| 80SQ-0550 | 550 | 490 | 1300 | Stock | 230V |

| 80SQ-0575 | 575 | 515 | 1375 | Stock | 230V |

| 80SQ-0600 | 600 | 540 | 1450 | Stock | 230V |

| 80SQ-0625 | 625 | 565 | 1525 | Stock | 230V |

| 80SQ-0650 | 650 | 590 | 1600 | Stock | 230V |

| 80SQ-0675 | 675 | 615 | 1675 | Build | 230V |

| 80SQ-0700 | 700 | 640 | 1750 | Stock | 230V |

| 80SQ-0725 | 725 | 665 | 1825 | Build | 230V |

| 80SQ-0750 | 750 | 690 | 1900 | Stock | 230V |

| 80SQ-0775 | 775 | 715 | 1975 | Build | 230V |

| 80SQ-0800 | 800 | 740 | 2050 | Stock | 230V |

| 80SQ-0850 | 850 | 790 | 2200 | Stock | 230V |

| 80SQ-0900 | 900 | 840 | 2350 | Stock | 230V |

| 80SQ-0950 | 950 | 890 | 2500 | Stock | 230V |

| 80SQ-1000 | 1000 | 940 | 2650 | Stock | 230V |

| 80SQ-1050 | 1050 | 990 | 2800 | Stock | 230V |

| 80SQ-1100 | 1100 | 1040 | 2930 | Stock | 230V |

| 80SQ-1150 | 1150 | 1090 | 3060 | Stock | 230V |

| 80SQ-1200 | 1200 | 1140 | 3190 | Stock | 230V |

| 80SQ-1250 | 1250 | 1190 | 3320 | Stock | 230V |

| 80SQ-1300 | 1300 | 1240 | 3450 | Stock | 230V |

| 80SQ-1350 | 1350 | 1290 | 3580 | Stock | 230V |

| 80SQ-1400 | 1400 | 1340 | 3600 | Stock | 230V |

| 80SQ-1450 | 1450 | 1390 | 3600 | Stock | 230V |

| 80SQ-1500 | 1500 | 1240 | 3600 | Stock | 230V |