OVER-THE-SIDE IMMERSION HEATER

The over the side immersion heater offers a wide variety of styles and shapes to meet nearly all needs. Whether you are heating a small pail of water or a large tank of caustic, we have the right product for the job. If standard designs do not match the application, we offer fast delivery on most custom designs. Since direct immersion is 100% efficient and over the side immersion heaters require no tank modification these are the most easily used yet among the most effective means to heat your process. Used in tanks where through-the-wall heaters cannot be installed, portability is required, or where heaters must be removed for cleaning without emptying the tank. Suitable for freeze protection, for heating viscous materials to improve flow, or most open tank applications with proper sheath and watt density selection.

Watt Density Per Application

- 90 Watts Per Square Inch – For heating clean water only in commercial and/or residential applications. Element life is sacrificed in favor of a low initial heater cost.

- 60 and 45 Watts Per Square Inch – Industrial water heating – many aqueous solutions which are compatible with steel and Incoloy.

- 23 and 20 Watts Per Square Inch – For heat transfer oil, cleaners, high temperature air and gas heating.

- 15 and 12 Watts Per Square Inch For lubricating oils, medium viscosity oils, high temperature air and gas heating.

- 8 and 6 Watts Per Square Inch – For #5 and #6 fuel oil heating, viscous materials, raw crude oil, residual oils, high temperature air and gas heating.

FEATURES

- Lightweight and portable

- Self supporting

- All compatible materials

- Stainless steel elements; stainless steel riser and junction box

- Incoloy elements; stainless steel riser and junction box

- Steel elements; steel riser and junction box

- Watertight terminal housing with terminal block for wiring

- Thermowell for installation of thermostat

- Sludge legs

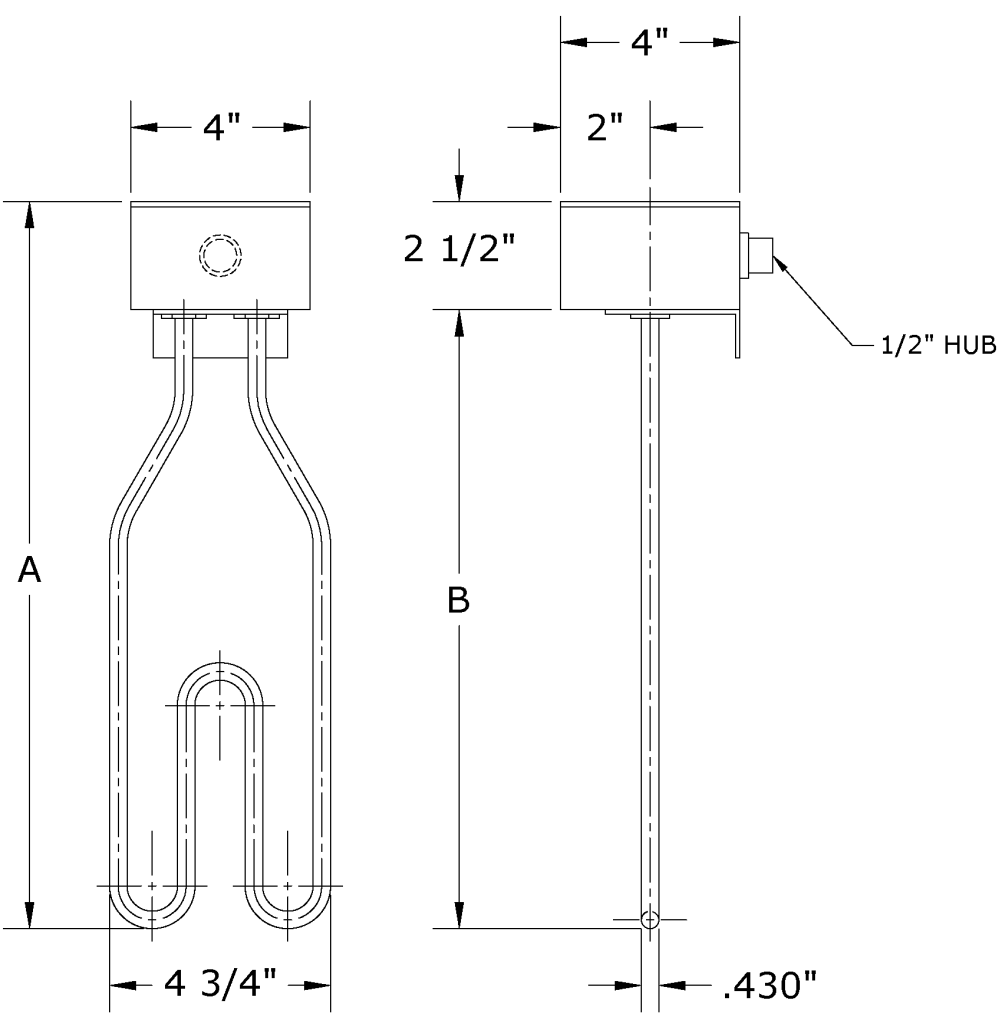

- .430″ diameter elements

OPTIONS

- Built-in thermostat: 0-100°F, 60-250°F, 50-250°C or 150-550°F

- Explosion Proof or Moisture Proof enclosures

- Passivated on wetted surfaces

- Built in contactors and control transformers

- Special sizes and ratings

- Special materials of construction

- Thermocouple for process control or high limit

- Various riser pipe heights

OVER THE SIDE -FORMED ELEMENT- TANK SIDE (SOS) SERIES

For industrial water heating and many other aqueous solutions which are generally “clear” and also compatible with both steel and Incoloy

Features

- Incoloy® 840 sheath

- Moisture tight PVC housing

- Stainless Steel bulkhead fittings

- Compact, low cost

- Stainless Steel hanging bracket

- UL & CSA Recognition on elements

STANDARD SIZES BELOW:

48 Watts per sq. inch – Water & Mild Solutions

|

SOS Series

|

||||

| 48 Watts per sq. inch – Water & Mild Solutions | ||||

|

Volts

1-Phase |

KW

|

A

|

B

|

Wt.

(lbs.) |

|

240

480 |

2

|

14 ⅜

|

11 ⅞

|

2

|

|

240

480 |

3

|

17 ⅞

|

15 ⅜

|

2 ½

|

|

240

480 |

4

|

21 ¾

|

19 ¼

|

3

|

|

240

480 |

5

|

25 ⅝

|

23 ⅛

|

3 ½

|

|

240

480 |

6

|

29 ¼

|

26 ¾

|

4

|

23 Watts per sq. inch – Oils & Stronger Corrosives

| 23 Watts per sq. inch – Oils & Stronger Corrosives | ||||

|

Volts

1-Phase |

KW

|

A

|

C

|

Wt.

(lbs.) |

|

240

480 |

1

|

14 ⅜

|

11 ⅞

|

2

|

|

240

480 |

1.5

|

17 ⅞

|

15 ⅜

|

2 ½

|

|

240

480 |

2

|

21 ¾

|

19 ¼

|

3

|

|

240

480 |

2.5

|

25 ⅝

|

23 ⅛

|

3 ½

|

|

240

480 |

3

|

29 ¼

|

26 ¾

|

4

|

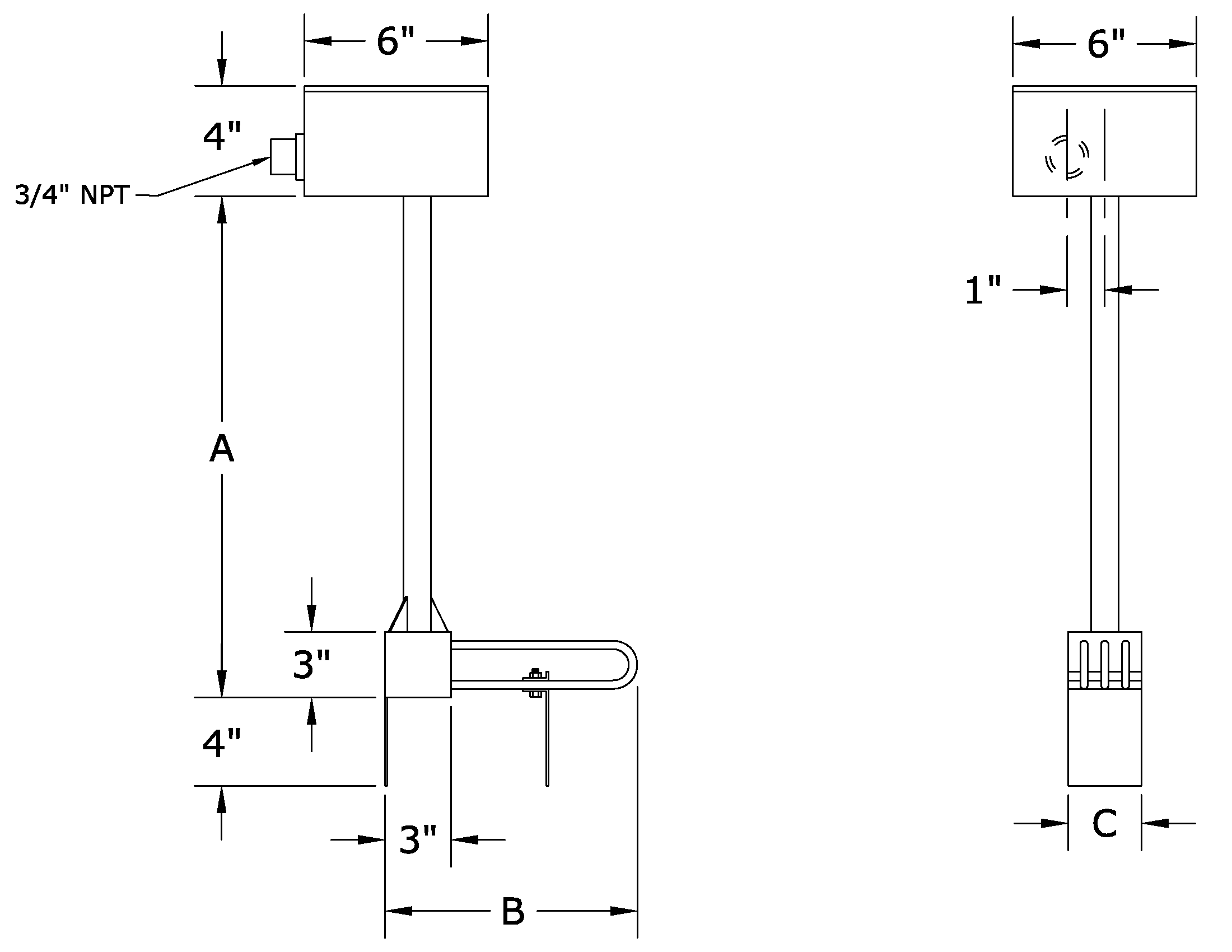

OVER THE SIDE - STRAIGHT ELEMENTS - TANK BOTTOM (ol) sERIES

Applications:

Type 304 Stainless Steel with Incoloy® 840 Elements

48 wsi – Water & Mild Solutions

23 wsi – Caustic & Stronger Solutions

Steel Construciton

23 wsi – Oils, Alkali Soaking Solutions & Degreasing Solutions

FEATURES

- PVC NEMA 4 housing

- ½” thermowell for optional thermostat

- 4″ sludge legs below elements

- All welded & pressure tested construction

- Moisture sealed riser pipe to avoid condensation

- Recompacted bends in heaters

6 ELEMENTS

|

6 ELEMENTS

|

|||||

| 48 Watts per sq. inch – Stainless Steel Construction | |||||

|

Volts

3-Phase |

KW

|

A

|

B

|

C

|

Wt.

(lbs.) |

|

240

480 |

6

|

36″

|

12″

|

6″

|

37

|

|

240

480 |

12

|

36″

|

22″

|

6″

|

40

|

|

240

480 |

18

|

36″

|

29″

|

6″

|

44

|

|

240

480 |

24

|

48″

|

37″

|

6″

|

48

|

|

240

480 |

30

|

48″

|

45″

|

6″

|

50

|

|

240

480 |

36

|

48″

|

52″

|

6″

|

52

|

|

240

480 |

40

|

48″

|

56″

|

6″

|

55

|

| 23 Watts per sq. inch – Stainless Steel Construction | |||||

|

Volts

3-Phase |

KW

|

A

|

B

|

C

|

Wt.

(lbs.) |

|

240

480 |

6

|

36″

|

22″

|

6″

|

40

|

|

240

480 |

9

|

36″

|

29″

|

6″

|

44

|

|

240

480 |

12

|

48″

|

37″

|

6″

|

48

|

|

240

480 |

15

|

48″

|

45″

|

6″

|

50

|

|

240

480 |

18

|

48″

|

52″

|

6″

|

52

|

|

240

480 |

20

|

48″

|

56″

|

6″

|

55

|

|

240

480 |

25

|

48″

|

69″

|

6″

|

61

|

| 23 Watts per sq. inch – Steel Construction | |||||

|

Volts

3-Phase |

KW

|

A

|

B

|

C

|

Wt.

(lbs.) |

|

240

480 |

6

|

36″

|

22″

|

6″

|

40

|

|

240

480 |

9

|

36″

|

29″

|

6″

|

44

|

|

240

480 |

12

|

48″

|

37″

|

6″

|

48

|

|

240

480 |

15

|

48″

|

45″

|

6″

|

50

|

|

240

480 |

18

|

48″

|

52″

|

6″

|

52

|

|

240

480 |

25

|

48″

|

69″

|

6″

|

61

|

3 ELEMENTS

|

3 ELEMENTS

|

|||||

| 48 Watts per sq. inch – Stainless Steel Construction | |||||

|

Volts

3-Phase |

KW

|

A

|

B

|

C

|

Wt.

(lbs.) |

|

240

480 |

3

|

36″

|

12″

|

3″

|

35

|

|

240

480 |

6

|

36″

|

22″

|

3″

|

38

|

|

240

480 |

9

|

36″

|

29″

|

3″

|

40

|

|

240

480 |

12

|

48″

|

37″

|

3″

|

43

|

|

240

480 |

15

|

48″

|

45″

|

3″

|

44

|

|

240

480 |

18

|

48″

|

52″

|

3″

|

45

|

|

240

480 |

20

|

48″

|

56″

|

3″

|

48

|

| 23 Watts per sq. inch – Stainless Steel Construction | |||||

|

Volts

3-Phase |

KW

|

A

|

B

|

C

|

Wt.

(lbs.) |

|

240

480 |

3

|

36″

|

22″

|

3″

|

38

|

|

240

480 |

4.5

|

36″

|

29″

|

3″

|

40

|

|

240

480 |

6

|

48″

|

37″

|

3″

|

43

|

|

240

480 |

7.5

|

48″

|

45″

|

3″

|

44

|

|

240

480 |

9

|

48″

|

52″

|

3″

|

45

|

|

240

480 |

10

|

48″

|

56″

|

3″

|

48

|

|

240

480 |

12.5

|

48″

|

69″

|

3″

|

54

|

| 23 Watts per sq. inch – Steel Construction | |||||

|

Volts

3-Phase |

KW

|

A

|

B

|

C

|

Wt.

(lbs.) |

|

240

480 |

3

|

36″

|

22″

|

3″

|

38

|

|

240

480 |

4.5

|

36″

|

29″

|

3″

|

40

|

|

240

480 |

6

|

48″

|

37″

|

3″

|

43

|

|

240

480 |

7.5

|

48″

|

45″

|

3″

|

44

|

|

240

480 |

9

|

48″

|

52″

|

3″

|

45

|

|

240

480 |

12.5

|

48″

|

69″

|

3″

|

54

|

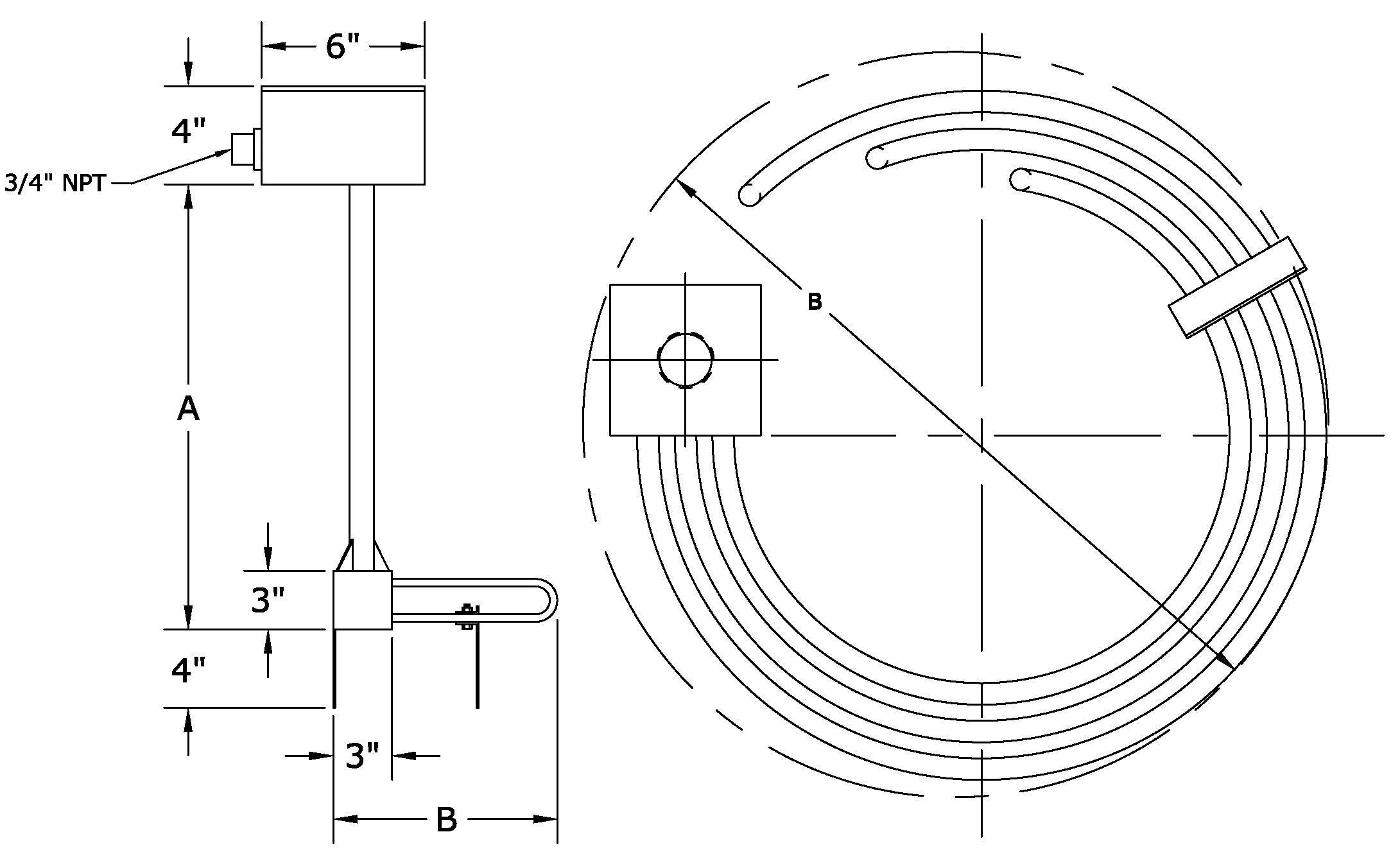

OVER THE SIDE -CURVED ELEMENTS- TANK BOTTOM (OR) SERIES

Type 304 Stainless Steel with Incoloy® 840 Elements

48 wsi – Water & Mild Solutions

23 wsi – Caustic & Stronger Solutions

Steel Construction

23 wsi – Oils, Alkali Soaking Solutions & Degreasing Solutions

Features

- PVC NEMA 4 housing

- ½” thermowell for optional thermostat

- 4″ sludge legs below elements

- All welded & pressure tested construction

- Moisture sealed riser pipe to avoid condensation

6 elements

|

6 ELEMENTS

|

||||

| 48 Watts per sq. inch – Stainless Steel Construction | ||||

|

Volts

1-Phase |

KW

|

A

|

B

|

Wt.

(lbs.) |

|

240

480 |

6

|

36″

|

16 ¾”

|

37

|

|

240

480 |

12

|

36″

|

19 ½”

|

40

|

|

240

480 |

18

|

36″

|

22″

|

44

|

|

240

480 |

24

|

48″

|

24 ½”

|

48

|

|

240

480 |

30

|

48″

|

27 ¼”

|

50

|

|

240

480 |

36

|

48″

|

29 ½”

|

52

|

|

240

480 |

40

|

48″

|

31″

|

55

|

| 23 Watts per sq. inch – Stainless Steel Construction | ||||

|

Volts

1-Phase |

KW

|

A

|

B

|

Wt.

(lbs.) |

|

240

480 |

6

|

36″

|

19 ½”

|

40

|

|

240

480 |

9

|

36″

|

22″

|

44

|

|

240

480 |

12

|

48″

|

24 ½”

|

48

|

|

240

480 |

15

|

48″

|

27 ¼”

|

50

|

|

240

480 |

18

|

48″

|

29 ½”

|

52

|

|

240

480 |

20

|

48″

|

31″

|

55

|

|

240

480 |

25

|

48″

|

34″

|

61

|

| 23 Watts per sq. inch – Steel Construction | ||||

|

Volts

1-Phase |

KW

|

A

|

B

|

Wt.

(lbs.) |

|

240

480 |

6

|

36″

|

19 ½”

|

40

|

|

240

480 |

9

|

36″

|

22″

|

44

|

|

240

480 |

12

|

48″

|

24 ½”

|

48

|

|

240

480 |

15

|

48″

|

27 ¼”

|

50

|

|

240

480 |

18

|

48″

|

29 ½”

|

52

|

|

240

480 |

25

|

48″

|

34″

|

61

|

3 elements

|

3 ELEMENTS

|

||||

| 48 Watts per sq. inch – Stainless Steel Construction | ||||

|

Volts

1-Phase |

KW

|

A

|

B

|

Wt.

(lbs.) |

|

240

480 |

3

|

36″

|

10 ¾”

|

35

|

|

240

480 |

6

|

36″

|

13 ½”

|

38

|

|

240

480 |

9

|

36″

|

16″

|

40

|

|

240

480 |

12

|

48″

|

18 ½”

|

43

|

|

240

480 |

15

|

48″

|

21 ¼”

|

44

|

|

240

480 |

18

|

48″

|

23 ½”

|

45

|

|

240

480 |

20

|

48″

|

25″

|

48

|

| 23 Watts per sq. inch – Stainless Steel Construction | ||||

|

Volts

1-Phase |

KW

|

A

|

B

|

Wt.

(lbs.) |

|

240

480 |

3

|

36″

|

13 ½”

|

38

|

|

240

480 |

4.5

|

36″

|

16″

|

40

|

|

240

480 |

6

|

48″

|

18 ½”

|

43

|

|

240

480 |

7.5

|

48″

|

21 ¼”

|

44

|

|

240

480 |

9

|

48″

|

23 ½”

|

45

|

|

240

480 |

10

|

48″

|

25″

|

48

|

|

240

480 |

12.5

|

48″

|

28″

|

54

|

| 23 Watts per sq. inch – Steel Construction | ||||

|

Volts

1-Phase |

KW

|

A

|

B

|

Wt.

(lbs.) |

|

240

480 |

3

|

36″

|

13 ½”

|

38

|

|

240

480 |

4.5

|

36″

|

16″

|

40

|

|

240

480 |

6

|

48″

|

18 ½”

|

43

|

|

240

480 |

7.5

|

48″

|

21 ¼”

|

44

|

|

240

480 |

9

|

48″

|

23 ½”

|

45

|

|

240

480 |

12.5

|

48″

|

28″

|

54

|

OVER THE SIDE - VERTICAL LOOP (VO) SERIES

FEATURES:

- Moisture proof terminal enclosure

- Simple installation

- Maximum working space in tank due to thin profile

Applications:

Oils, water, mild corrosives

Standard sizes

|

Sheath Material

|

Volts

1-Phase |

KW

|

w/in2

|

Wt.

(lbs.) |

|

STEEL

|

240

480 |

5

|

25

|

20

|

|

240

480 |

7.5

|

40

|

20

|

|

|

COPPER

|

240

480 |

5

|

25

|

20

|

|

240

480 |

7.5

|

40

|

20

|

|

|

INCOLOY® 840

|

240

480 |

5

|

25

|

20

|

|

240

480 |

7.5

|

40

|

20

|

Over the Side Immersion Options

- BUILT IN THERMOSTATS

- MOISTURE PROOF

- EXPLOSION PROOF

- EXPLOSION PROOF No Thermostat

- Other optional Features

|

Series

Used On |

Range

|

No.

Poles |

Max.

Amps/Volts |

Catalog Number

|

|

|

Moisture Proof

|

Explosion Proof

|

||||

|

SOS, OL & OR

|

0-100°F

|

2

|

25@277V

|

N4T4

|

N7T4

|

|

SOS, OL & OR

|

60-250°F

|

2

|

25@277V

|

N4T5

|

N7T5

|

|

SOS, OL & OR

|

50-250°F

|

2

|

21@480V

|

N4T5R

|

N7T5R

|

|

SOS, OL & OR

|

150-550°F

|

2

|

25@277V

|

N4T6

|

N7T6

|

|

SOS, OL & OR

|

150-550°F

|

2

|

21@480V

|

N4T6R

|

N7T6R

|

|

Series Used On

|

Catalog No.

|

|

SOS, OL, OR

|

N7

|

Passivated on wetted surfaces

Built in contactors and control transformers

Special sizes and ratings

Special materials of construction

Various riser pipes heights