Pressure Torch™

Pressure Torch™ heaters are highly efficient and ideal for heating large airflows. Some of the advantages these process heaters offer are:

- Minimal obstruction to airflow (low pressure drop)

- Ideal for medium pressure (up to 150PSI) blowers

- Support high volume air flow (up to 2000SCFM)

- Heat air up to 482°C (900°F)

- Fast heat up and cool down due to low mass open coil design

- Connected via flange fittings

Farnam has developed three graduated sizes of this platform as an evolution of our popular Flow Torch product line. This family of heaters is offered as a standard product with several wattage and voltage options. Farnam offers application assistance so you can best match the heater to your requirements and needs. Control packages are available and encouraged for these heaters. Pressure Drop Charts are available for quick comparison. Regenerative Blowers available with complete systems.

Pressure Torch™ 400

| MAX WATT | MAX INLET | MAX EXHAUST | MIN SCFM | MAX SCFM | PSIG* |

|---|---|---|---|---|---|

| 35000 W | 250 °F | 900 °F | 19 | 500 | 150 |

Standard power of 2 kW to 75 kW is available for a wide range of applications, including:

The Pressure Torch™ 400 is an open coil air heater designed for high flow rates at low pressure drop due to its efficient design with minimal flow restrictions. The robust construction of this 4” diameter stainless steel heater offers reliable long-life performance and reduced operational cost.

The Pressure Torch™ 400 incorporates a spiral wound element of the highest grade material, providing quick heat up and cool down cycles with maximum heat transfer.

The Pressure Torch™ 400 is capable of operating with airflow of 500 SCFM and a maximum operating pressure of 150 PSIG. Maximum output temperature is 482°C (900°F).

Regenerative Blowers available with complete systems.

- Mounting…………………………………….Horizontal/Vertical

- Heater Body………………………………Stainless Steel

- Inlet Fittings………………………………Stainless Steel

- Exhaust Fittings………………………Stainless Steel

Pressure Torch™ 600

| MAX WATT | MAX INLET | MAX EXHAUST | MIN SCFM | MAX SCFM | PSIG* |

|---|---|---|---|---|---|

| 60000 W | 250 °F | 900 °F | 38 | 1100 | 150 |

Standard power of 2 kW to 75 kW is available for a wide range of applications, including:

The Pressure Torch™ 600 is an open coil air heater designed for high flow rates at low pressure drop due to its efficient design with minimal flow restrictions. The robust construction of this 6” diameter stainless steel heater offers reliable long-life performance and reduced operational cost.

The Pressure Torch™ 600 incorporates a spiral wound element of the highest grade material, providing quick heat up and cool down cycles with maximum heat transfer.

The Pressure Torch™ 600 is capable of operating with airflow of 1100 SCFM and a maximum operating pressure of 150 PSIG. Maximum output temperature is 482 °C (900 °F).

Regenerative Blowers available with complete systems.

- Mounting…………………………………….Horizontal/Vertical

- Heater Body………………………………Stainless Steel

- Inlet Fittings………………………………Stainless Steel

- Exhaust Fittings………………………Stainless Steel

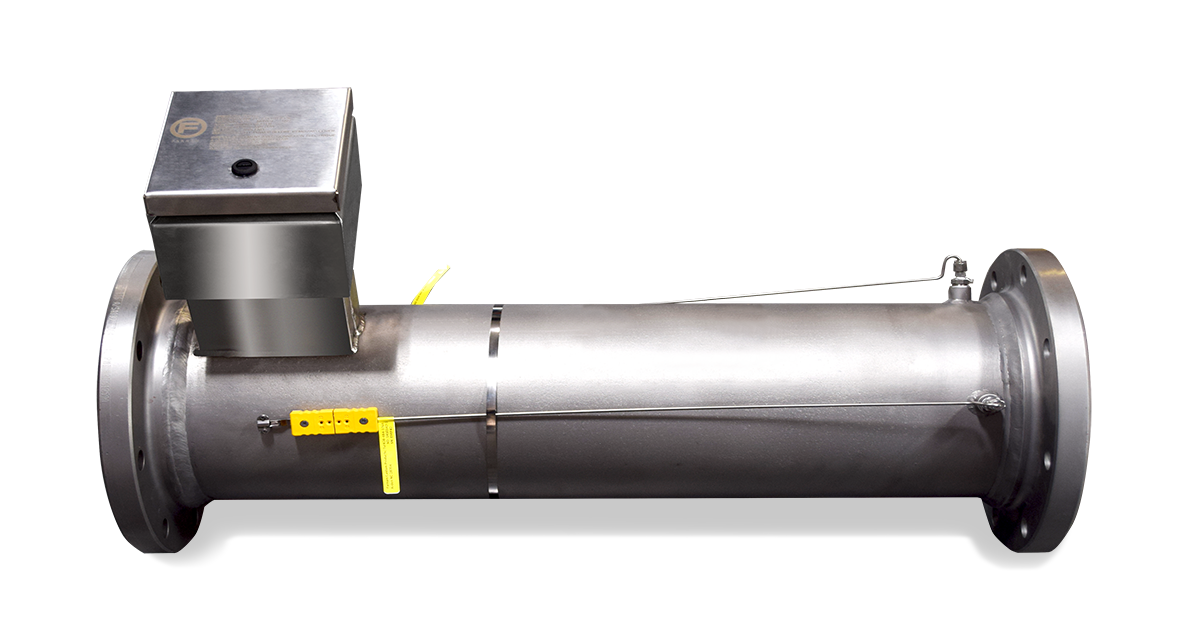

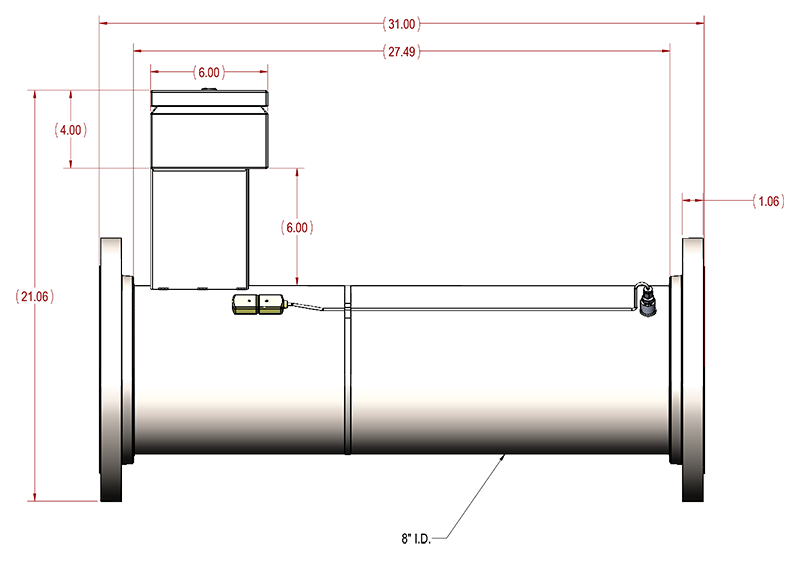

Pressure Torch™ 800

| MAX WATT | MAX INLET | MAX EXHAUST | MIN SCFM | MAX SCFM | PSIG* |

|---|---|---|---|---|---|

| 75000 W | 250 °F | 900 °F | 76 | 2000 | 150 |

Standard power of 2 kW to 75 kW is available for a wide range of applications, including:

The Pressure Torch™ 800 is an open coil air heater designed for high flow rates at low pressure drop due to its efficient design with minimal flow restrictions. The robust construction of this 8” diameter stainless steel heater offers reliable long-life performance and reduced operational cost.

The Pressure Torch™ 800 incorporates a spiral wound element of the highest-grade material, providing quick heat up and cool down cycles with maximum heat transfer.

The Pressure Torch™ 800 is capable of operating with airflow of 2000 SCFM and a maximum operating pressure of 150 PSI. Maximum output temperature is 482°C (900°F).

Regenerative Blowers available with complete systems.

- Mounting…………………………………….Horizontal/Vertical

- Heater Body………………………………Stainless Steel

- Inlet Fittings………………………………Stainless Steel

- Exhaust Fittings………………………Stainless Steel