FLEXIBLE HEATERS

Southeast Thermal Systems offers designs of heating elements that are either wire wound or etched foil, depending on the application and the heater’s requirements. Our products are Flexible Heaters, Polyester Film, Kapton® Polyimide, High Temperature Mica, Ceramic and Enclosure Heaters. We manufacture drop-in subassemblies with sensors, thermostats, fuses, cords and plugs. A combination of insulating materials is used.

Our heater products warm batteries in telecommunications cabinets, dry the ink in silk screening machines, cure the film on airplane windshields, heat laboratory samples, or maintain an animal’s body heat during veterinary operations, to name just a few applications.

Selection of Flexible Heaters etch foil heaters, silicon rubber wire-wound heaters, Kapton® heaters, as well as drum and pail heaters area. Type W flanged can also be attached to Fig. U unheated section on stock items.

FLEXIBLE SILICONE RUBBER HEATERS

|

Preform Heater with Thermostat

|

Ball-Valve Heater

|

Flexible heaters provide dependable performance under rigorous conditions. Ambient temperatures down to –80°F and up to 500°F do not diminish performance.

These heaters can be designed and fabricated in many types of configurations to fit the size and shape required in your application.

- Long life

- High reliability

- Versatile configurations

- Flexible for flat or curved installation

- Withstand extreme ambient temperatures

Etched Foil

Our designers use custom software to calculate the configuration of the heating element, given the voltage, wattage and resistance.

The etched element provides superior heat transfer and exceptionally uniform heat output, which results in a faster warm-up cycle and longer life. The heaters operate in ambient temperatures from 500°F to -80°F.

Advantages over wire wound heating elements:

- Higher watt densities

- Distributed wattages

- Elimination of edge loss compensation

- Greater element area over heater sheath

- Higher production quantities

- Complex heat distribution with a rating of about 200°C (392°F)

- Economical mass production

- Reproduction of complex circuits

Wire Wound

The excellent dielectric properties of silicone rubber and the strength of fiberglass combine to produce a unique heater. First, fine nickel-chromium alloy wire is spiraled onto a center core of fiberglass twine, producing a strong, flexible heating element. Precision electronically-controlled winding equipment ensures consistency.

Circuits are then hand-wound on permanent tooling providing repeatability of resistance and pattern. Parallel circuits are utilized where possible, permitting continued operation should a single circuit be damaged.

When the heating element is positioned, a second layer of silicone rubber is laid over the wire. The layers are then vulcanized to permanently position the circuits.

Using these versatile and flexible heaters, the ability to apply heat exactly where required is limited only by imagination—and a maximum continuous operating temperature of about 200°C (392°F).

Flexible heaters resist:

- Outdoor exposure

- Many chemicals

- Vibration

- Mechanical shock

- Deterioration by moisture

- Ripping

- Stretching

- Separation

- Thermal shock

MICA ETCHED FOIL HEATERS

POLYESTER FILM HEATERS

Polyester heaters are used to heat large areas very economically. These heaters can be designed and fabricated in many types of configurations to fit the size and shape required in your application. They have many uses in medical equipment, restaurant equipment, warming batteries or deicing. The maximum surface temperature for the polyester heater is 105° C (221° F).

- Long life

- High reliability

- Economical in large sizes

- Versatile configurations

Etched Foil

The etched element has superior heat transfer and exceptionally uniform heat output, which results in a faster warm-up cycle and longer life. Use this heater to cover large areas with even heat, for flat or gently curved surfaces. Polyester is UL recognized with 105° C (221° F) surface temperature in the application.

Etched foil polyester heaters can be designed and fabricated in many types of configurations to fit the size and shape required in your application.

Due to the resistance limits of the foil materials, as circuits become larger the economics of foil versus resistance wire become less attractive.

Our designers use a custom computer-aided design program to calculate the design, given the voltage, wattage and resistance.

Advantages of the etched foil versus wire wound heating elements are:

- Low wattage sq/in

- Distributed wattage

- Edge loss compensation

- Very small sizes of heaters can be precisely manufactured

- Complex heat distribution with a rating of about 105°C (221°F)

- Economical mass production

- Accurate reproduction of complex circuits

Wire Wound

Polyester film heaters have a maximum service temperature of 105° C (221° F). They are used to cover large areas with even heat, for flat or gently curved surfaces. Polyester film heaters can be designed and fabricated in many configurations to fit the size and shape required in your application.

Reliable Heating Elements

Here in the Hi-Heat manufacturing facility, fine nickel-chromium alloy wire is spiraled onto a center core of fiberglass twine to produce a strong, flexible element. Our proprietary winding equipment is electronically controlled to assure consistency. Post-production inspections assure quality and accuracy.

Circuits are hand-wound on tooling patterns custom-designed for the appropriate resistance. Parallel circuits are utilized as possible, permitting continued operation should a single circuit be damaged.

The precision wound resistance element is then positioned between two layers of polyester. Vulcanization permanently encapsulates the wire.

The polyester heaters are characterized by the following:

- Excellent electrical properties

- High thermal durability

- Low moisture absorption

- Low shrinkage

- Exceptional cut-through resistance

- Ability to perform in humid or moisture-laden environments

- Easy application with adhesives

- Lower cost than silicone

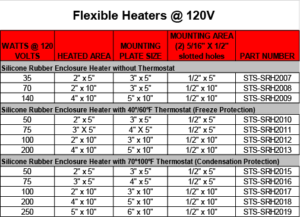

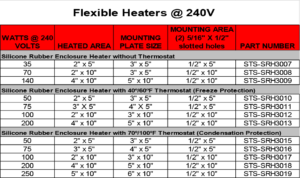

ENCLOSURE HEATERS

Enclosure heaters are a necessity when protection from condensation and/or freezing is required. These heaters can be ordered with an adhesive backing, or they can be factory vulcanized to an aluminum plate. The plate will have a flange for easy bolt in assembly. If your application requires it, an air sensing thermostat can be installed in-line, bonded to the heater or mounted remotely.

Kapton/POLYIMIDE HEATERS ETCHED FOIL

Kapton®, polyimide is a lightweight flexible film that maintains outstanding mechanical, chemical and electrical properties over extreme temperature ranges. Polyimide has more than 35 years of proven performance as the flexible material of choice in applications involving high, 200°C (392°F), and very low, -195°C (-319°F), temperatures.

These low thermal mass heaters have fast warm-ups and quick response because the elements run cooler, they have longer life as well. Polyimide’s properties and the moisture resistant construction make these heaters the preferable product in high humidity areas, wash down zones and in applications requiring repeated sterilizations. They are also ideal for service in harsh environments.

Etched foil polyimide heaters can be fabricated in an unlimited range of shapes, sizes and wattages. Their thin, lightweight design (0.005″ thick) allows close thermal contact for maximum heating efficiency, and also permits close adaptation to the contours of the part.

Hi-Heat Industries designs these heaters with distributed wattages, eliminating edge loss compensation. Superior heat transfer and exceptionally uniform heat output result in a faster warm-up cycle and longer life.

Kapton® is a registered trademark of DuPont™.

Polyimide has excellent:

- Tensile strength

- Dimensional stability

- Tear resistance

- Cut-through resistance

- High dielectric strength

- Minimal outgassing in high vacuum environments

- Resistance to radiation, fungus, oil and most chemicals

THERMOSTATS & THERMAL FUSES

Heaters can be fabricated with thermostats, thermal fuses, thermocouples and resistance temperature detectors (RTD) as an integral part of the heater.

Temperature Sensors

Sensors can be located to monitor either heater surface or part temperature. Small sensors are held in place with a protective cover of silicone rubber/fiberglass vulcanized to the heater body. Larger sensors and thermostats have a protective cover (overmold) that is bonded to the heater body.

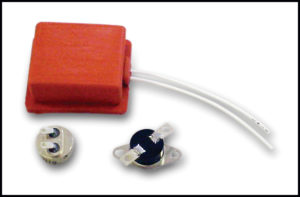

Mechanical Thermostats( Creep Action | Snap Action )

There are two basic types of mechanical thermostats: Creep Action and Snap Action.

Both are based on a bimetal expansion-contraction principle and nearly all are pre-set to a specific temperature (non-adjustable). If the application requires very close temperature control an electronic controller with sensor is suggested over the mechanical thermostat.

Freeze protection, enclosure temperature and high limit protection are the applications best suited for the low cost mechanical thermostat.

Creep Action

The creep action units are constructed with a bimetal strip that curves with the temperature excursions to provide the mechanical action of make and break for the contacts. This provides a close differential between on/off, but can cause radio frequency interference in enclosures that have sensitive electronics. The temperature setting is factory preset and has the range of between 40°F and 300°F, +/- 5°F. Maximum amperage of these units is 8 amps at 120 volts. These small thermostats are commonly used as motor protectors or over temperature protectors in appliance applications.

Snap Action

The snap action units are round in construction (approx 5/8” dia.) due to the bimetal disk that provides the snap action. The disk is shaped similar to a contact lens and snaps back and forth at a pre-set temperature to make and break the contact points. The pros and cons of these types of units are:

- Due to the energy required to snap the disk over center, the temperature differential between on and off is 20° to 30°F. When used as a high limit over 300°F this differential can be as large as 75°F. Maximum temperature for high limit is 500°F.

- The wide differential does not provide narrow band temperature control but also does not generate any radio frequency interference due to the positive make/break action.

- The most common use for these units is freeze protection and enclosure control with a setting of On at 40°F / Off at 60°F.

- These units must be covered with an overmold that is bonded to the heater.

Thermal Fuses

Thermal fuses open the circuit if the heater exceeds the selected fuse temperature. They are a one time over temperature protection device that can prevent heater runaway in the event that a control device has frozen in the on position. Testing is suggested to select the location and temperature setting of the fuse to protect your product most effectively.

Fuses are preset with a range of 150°F to 460°F. Electrical ratings are 120/250 VAC and 15 amp maximum. They must be covered or enclosed because the outer case of the fuse is electrically live.

Thermocouples & Resistance – Temperature Devices (RTD)

These devices are most commonly very small and can be attached to the heater with a patch of silicone rubber/fiberglass. Almost any type thermocouple can be used. Type ”J” is most commonly employed.

RTDs are either 100 Ohm or 1000 Ohm two conductor type. Special sensors can be provided to your specifications and we can mount customer-supplied sensors.

FLEXIBLE HEATERS

Flexible heaters provide dependable performance under rigorous conditions. Ambient temperatures down to –80°F and up to 500°F do not diminish performance.

These heaters can be designed and fabricated in many types of configurations to fit the size and shape required in your application.

- Long life

- High reliability

- Versatile configurations

- Flexible for flat or curved installation

- Withstand extreme ambient temperatures

Etched Foil

Our designers use custom software to calculate the configuration of the heating element, given the voltage, wattage and resistance.

The etched element provides superior heat transfer and exceptionally uniform heat output, which results in a faster warm-up cycle and longer life. The heaters operate in ambient temperatures from 500°F to -80°F.

Advantages over wire wound heating elements:

- Higher watt densities

- Distributed wattages

- Elimination of edge loss compensation

- Greater element area over heater sheath

- Higher production quantities

- Complex heat distribution with a rating of about 200°C (392°F)

- Economical mass production

- Reproduction of complex circuits

Wire Wound

The excellent dielectric properties of silicone rubber and the strength of fiberglass combine to produce a unique heater. First, fine nickel-chromium alloy wire is spiraled onto a center core of fiberglass twine, producing a strong, flexible heating element. Precision electronically-controlled winding equipment ensures consistency.

Circuits are then hand-wound on permanent tooling providing repeatability of resistance and pattern. Parallel circuits are utilized where possible, permitting continued operation should a single circuit be damaged.

When the heating element is positioned, a second layer of silicone rubber is laid over the wire. The layers are then vulcanized to permanently position the circuits.

Using these versatile and flexible heaters, the ability to apply heat exactly where required is limited only by imagination—and a maximum continuous operating temperature of about 200°C (392°F).

Silicone rubber heaters resist:

- Outdoor exposure

- Many chemicals

- Vibration

- Mechanical shock

- Deterioration by moisture

- Ripping

- Stretching

- Separation

- Thermal shock

MICA ETCHED FOIL HEATERS

POLYESTER FILM HEATERS

- Long life

- High reliability

- Economical in large sizes

- Versatile configurations

Etched Foil

The etched element has superior heat transfer and exceptionally uniform heat output, which results in a faster warm-up cycle and longer life. Use this heater to cover large areas with even heat, for flat or gently curved surfaces. Polyester is UL recognized with 105° C (221° F) surface temperature in the application.

Etched foil polyester heaters can be designed and fabricated in many types of configurations to fit the size and shape required in your application.

Due to the resistance limits of the foil materials, as circuits become larger the economics of foil versus resistance wire become less attractive.

Our designers use a custom computer-aided design program to calculate the design, given the voltage, wattage and resistance.

Advantages of the etched foil versus wire wound heating elements are:

- Low wattage sq/in

- Distributed wattage

- Edge loss compensation

- Very small sizes of heaters can be precisely manufactured

- Complex heat distribution with a rating of about 105°C (221°F)

- Economical mass production

- Accurate reproduction of complex circuits

Wire Wound

Polyester film heaters have a maximum service temperature of 105° C (221° F). They are used to cover large areas with even heat, for flat or gently curved surfaces. Polyester film heaters can be designed and fabricated in many configurations to fit the size and shape required in your application.

Reliable Heating Elements

Here in the Hi-Heat manufacturing facility, fine nickel-chromium alloy wire is spiraled onto a center core of fiberglass twine to produce a strong, flexible element. Our proprietary winding equipment is electronically controlled to assure consistency. Post-production inspections assure quality and accuracy.

Circuits are hand-wound on tooling patterns custom-designed for the appropriate resistance. Parallel circuits are utilized as possible, permitting continued operation should a single circuit be damaged.

The precision wound resistance element is then positioned between two layers of polyester. Vulcanization permanently encapsulates the wire.

The polyester heaters are characterized by the following:

- Excellent electrical properties

- High thermal durability

- Low moisture absorption

- Low shrinkage

- Exceptional cut-through resistance

- Ability to perform in humid or moisture-laden environments

- Easy application with adhesives

- Lower cost than silicone

ENCLOSURE HEATERS

KAPTON/POLYIMIDE HEATERS ETCHED FOIL

These low thermal mass heaters have fast warm-ups and quick response because the elements run cooler, they have longer life as well. Polyimide’s properties and the moisture resistant construction make these heaters the preferable product in high humidity areas, wash down zones and in applications requiring repeated sterilizations. They are also ideal for service in harsh environments.

Etched foil polyimide heaters can be fabricated in an unlimited range of shapes, sizes and wattages. Their thin, lightweight design (0.005″ thick) allows close thermal contact for maximum heating efficiency, and also permits close adaptation to the contours of the part.

Hi-Heat Industries designs these heaters with distributed wattages, eliminating edge loss compensation. Superior heat transfer and exceptionally uniform heat output result in a faster warm-up cycle and longer life.

Kapton® is a registered trademark of DuPont™.

Polyimide has excellent:

- Tensile strength

- Dimensional stability

- Tear resistance

- Cut-through resistance

- High dielectric strength

- Minimal outgassing in high vacuum environments

- Resistance to radiation, fungus, oil and most chemicals

THERMOSTATS & THERMAL FUSES

Heaters can be fabricated with thermostats, thermal fuses, thermocouples and resistance temperature detectors (RTD) as an integral part of the heater.

Temperature Sensors

Sensors can be located to monitor either heater surface or part temperature. Small sensors are held in place with a protective cover of silicone rubber/fiberglass vulcanized to the heater body. Larger sensors and thermostats have a protective cover (overmold) that is bonded to the heater body.

Mechanical Thermostats( Creep Action | Snap Action )

There are two basic types of mechanical thermostats: Creep Action and Snap Action.

Both are based on a bimetal expansion-contraction principle and nearly all are pre-set to a specific temperature (non-adjustable). If the application requires very close temperature control an electronic controller with sensor is suggested over the mechanical thermostat.

Freeze protection, enclosure temperature and high limit protection are the applications best suited for the low cost mechanical thermostat.

Creep Action

The creep action units are constructed with a bimetal strip that curves with the temperature excursions to provide the mechanical action of make and break for the contacts. This provides a close differential between on/off, but can cause radio frequency interference in enclosures that have sensitive electronics. The temperature setting is factory preset and has the range of between 40°F and 300°F, +/- 5°F. Maximum amperage of these units is 8 amps at 120 volts. These small thermostats are commonly used as motor protectors or over temperature protectors in appliance applications.

Snap Action

The snap action units are round in construction (approx 5/8” dia.) due to the bimetal disk that provides the snap action. The disk is shaped similar to a contact lens and snaps back and forth at a pre-set temperature to make and break the contact points. The pros and cons of these types of units are:

- Due to the energy required to snap the disk over center, the temperature differential between on and off is 20° to 30°F. When used as a high limit over 300°F this differential can be as large as 75°F. Maximum temperature for high limit is 500°F.

- The wide differential does not provide narrow band temperature control but also does not generate any radio frequency interference due to the positive make/break action.

- The most common use for these units is freeze protection and enclosure control with a setting of On at 40°F / Off at 60°F.

- These units must be covered with an overmold that is bonded to the heater.

Thermal Fuses

Thermal fuses open the circuit if the heater exceeds the selected fuse temperature. They are a one time over temperature protection device that can prevent heater runaway in the event that a control device has frozen in the on position. Testing is suggested to select the location and temperature setting of the fuse to protect your product most effectively.

Fuses are preset with a range of 150°F to 460°F. Electrical ratings are 120/250 VAC and 15 amp maximum. They must be covered or enclosed because the outer case of the fuse is electrically live.

Thermocouples & Resistance – Temperature Devices (RTD)

These devices are most commonly very small and can be attached to the heater with a patch of silicone rubber/fiberglass. Almost any type thermocouple can be used. Type ”J” is most commonly employed.

RTDs are either 100 Ohm or 1000 Ohm two conductor type. Special sensors can be provided to your specifications and we can mount customer-supplied sensors.

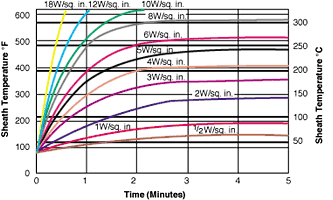

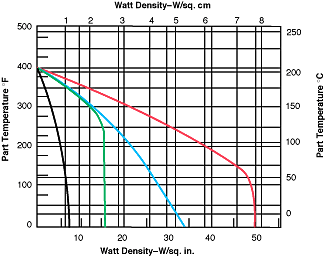

SURFACE TEMPERATURE vs TIME FOR SILICONE RUBBER HEATERS

MAXIMUM WATT DENSITY

The area where leads are attached adds additional thickness depending upon gauge wire used and type. 12″ leads are standard. Gauge of wire to be determined based on amperage or other considerations. Composite Bonding Processes and other applications may require special heat pattern or uniformity. Heat Mapping Certification is available as an option. Underwriter’s Laboratory and CSA recognition or listing apply to most configurations