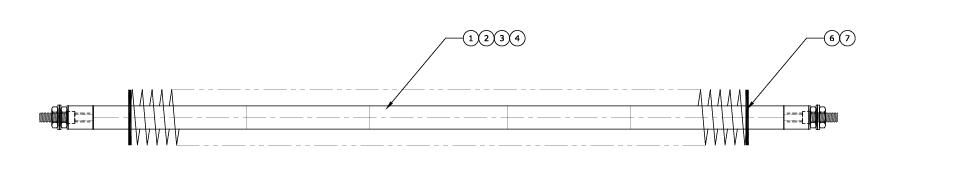

FINNED TUBULAR HEATING ELEMENTS

finned tubular heaters are suitable for use in a wide variety of forced air heating applications. The steel units are suitable for applications where the sheath temperature will not exceed 850° F. For higher temperatures or in applications where corrosion is a problem these can be made in stainless steel or monel.

Units can be assembled in a frame to provide a compact duct heater. Because of the greater surface area provided by the heat transfer fins, it is possible to fabricate units providing greater kW capacities, with lower operating temperatures.

Features of Finned Tubular Heaters are:

- Seamless steel sheath material.

- High purity MgO Powder, compacted to provide maximum heat conductivity and optimum dielectric strength.

- Type ‘A’ 80/20 resistance wire sized to provide the lowest wire watt density for maximum life, precision wound to provide uniform heat flux over length of element.

- Fusion welded junction between cold pin resistance wire giving superior life.

- Bends recompacted to restore MgO density on formed units.

- Continuous steel fin edge wound and copper brazed to heater sheath. This provides maximum heat transfer from sheath to fin, without vibration.

- Fin and sheath are painted with high temperature aluminum paint to resist oxidation.

Optional Features are:

- Threaded fittings for mounting

- Ceramic to metal end seals for high temperature or corrosive environments

- Other sheath and fin materials

- High temperature ceramic coating

- Custom bracket mountings

- Custom terminal options

- Also available in smaller diameter units

TUBULAR HEATING OPTIONS

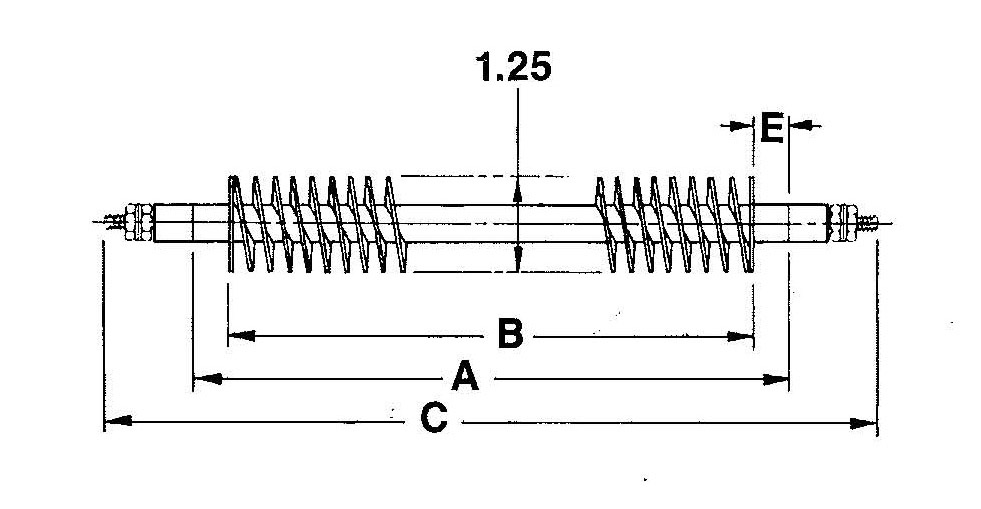

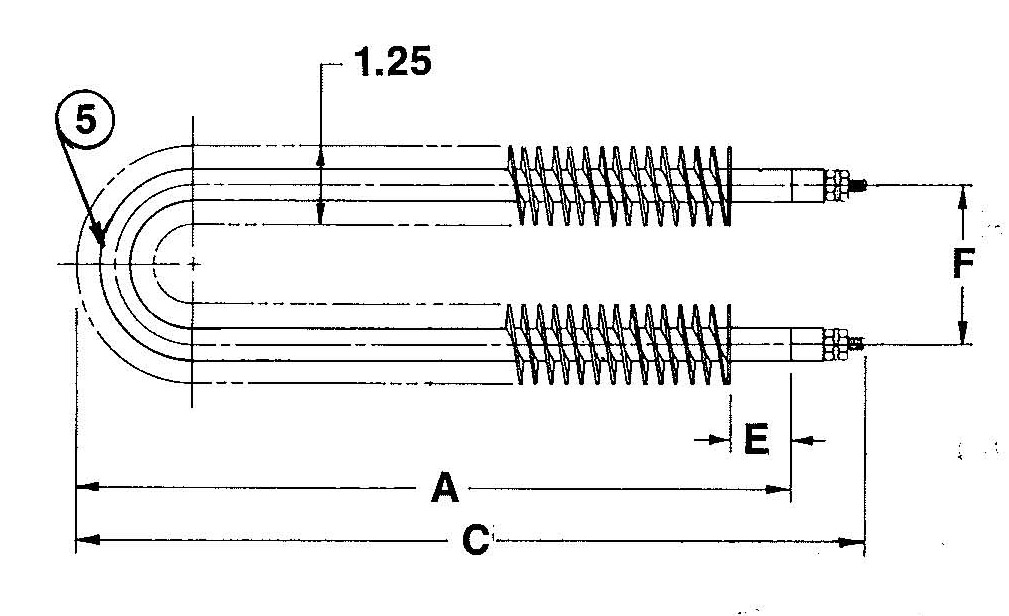

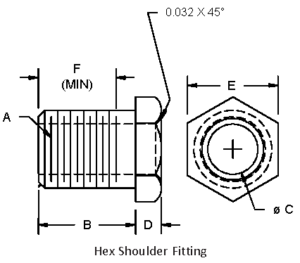

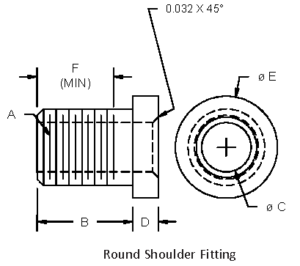

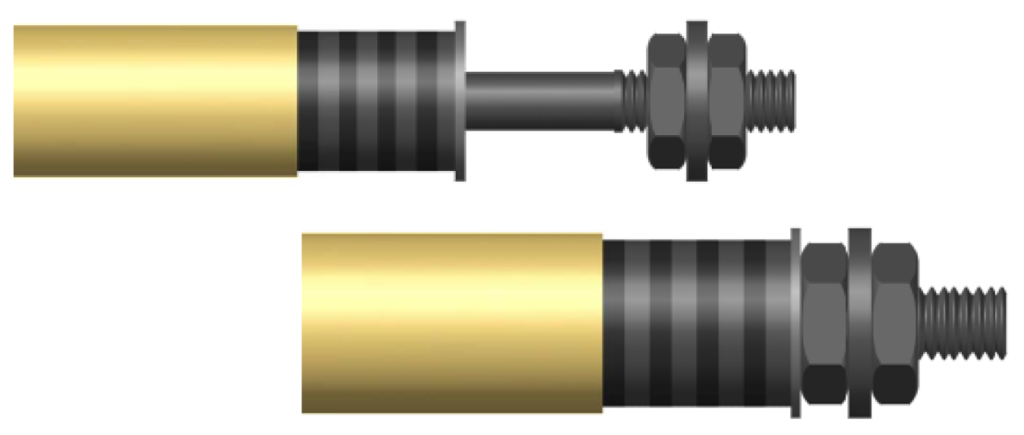

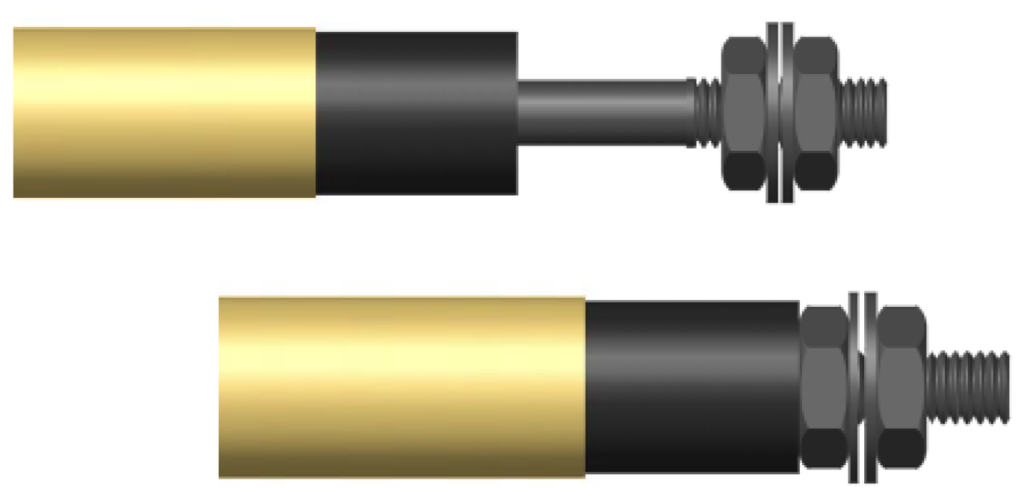

THREADED FITTINGS

Threaded fittings are furnished with nuts and optional fiber gaskets, washers and lockwashers. Fittings are silver soldered, welded or mechanically pressed (staked) to the sheath. Welding requires sheath and fitting material compatibility. Standard elements may be provided with two fittings, one for each terminal end. Two-pass elements may be provided with only one fitting.

THREADED FITTING CHART

| C Element Diameter |

Fitting Part No. | Shoulder Type | Material | A Thread Size |

B Length |

D Shoulder Thk |

E Head Size |

F Min. Thrd. Length |

| 0.250/0.260 | 60000425 | Hex | SST | 7/16-20UNF | 0.56 | 0.13 | 0.63 | 0.425+ |

| 0.250/0.260 | 60000428 | Hex | BRS | 1/2‐20UNF | 0.50 | 0.13 | 0.75 | 0.43 |

| 0.250/0.260 | 86-2-C-3 | Round | BRS | 1/2‐20UNF | 0.63 | 0.13 | 0.75 | 0.55 |

| 0.26 | 86-3-C-74 | Hex | BRS | 1/2‐20UNF | 0.69 | 0.19 | 0.75 | 0.61 |

| 0.32 | 60000326 | Hex | SST | 7/16-20UNF | 0.56 | 0.13 | 0.63 | 0.425+ |

| 0.32 | 1007121 | Round | BRS | 7/16-28UNEF | 0.56 | 0.31 | 0.75 | 0.51 |

| 0.32 | 86-22-C-1 | Hex | BRS | 1/2‐20UNF | 0.50 | 0.19 | 0.75 | 0.43 |

| 0.32 | 86-22-ZC-2* | Hex | BRS | 1/2‐20UNF | 0.50 | 0.19 | 0.75 | 0.43 |

| 0.32 | 86-3-UZ-1 | Hex | 303 SST | 1/2‐20UNF | 0.63 | 0.13 | 0.75 | 0.488+ |

| 0.32 | 60000431 | Round | SST | 1/2‐20UNF | 0.81 | 0.13 | 0.75 | 0.675+ |

| 0.32 | 1007139 | Round | BRS | 1/2‐20UNF | 0.88 | 0.31 | 0.75 | 0.80 |

| 0.32 | 86-37-C-1 | Hex | BRS | 1/2‐20UNF | 1.00 | 0.25 | 0.75 | 0.93 |

| 0.32 | 1007219 | Round | BRS | 9/16-18UNF | 0.50 | 0.13 | 1.00 | 0.42 |

| 0.32 | 1007142 | Round | BRS | 5/8-18UNF | 0.50 | 0.31 | 1.00 | 0.42 |

| 0.32 | 86-62-C-1 | Hex | BRS | 5/8-18UNF | 0.75 | 0.19 | 0.88 | 0.67 |

| 0.32 | 60000384 | Hex | SST | 5/8-18UNF | 0.81 | 0.13 | 0.88 | 0.73 |

| 0.38 | 60000324 | Hex | BRS | 1/2‐20UNF | 0.56 | 0.13 | 0.75 | 0.49 |

| 0.38 | 60000198 | Hex | 303 SST | 9/16-18UNF | 0.69 | 0.13 | 0.75 | 0.542+ |

| 0.38 | 86-3-UZ-81 | Hex | 303 SST | 9/16-18UNF | 1.00 | 0.13 | 0.88 | 0.854+ |

| 0.43 | 86-47-C-1 | Round | BRS | 9/16-18UNF | 1.00 | 0.25 | 0.75 | 0.92 |

| 0.43 | 86-36-C-2 | Hex | BRS | 5/8-18UNF | 0.50 | 0.19 | 0.88 | 0.42 |

| 0.43 | 60000320 | Hex | SST | 5/8-18UNF | 0.63 | 0.13 | 0.88 | 0.48 |

| 0.43 | 86-36-C-1 | Hex | BRS | 5/8-18UNF | 0.75 | 0.19 | 0.88 | 0.67 |

| 0.43 | 60000396 | Hex | SST | 5/8-18UNF | 1.00 | 0.13 | 0.88 | 0.854+ |

| 0.43 | 86-3-C-7 | Hex | BRS | 5/8-18UNF | 1.06 | 0.19 | 0.88 | 0.98 |

| 0.43 | 60000352 | Hex | BRS | 3/4-16UNF | 0.81 | 0.19 | 1.00 | 0.72 |

| 0.43 | 60000337 | Hex | SST | 3/4-16UNF | 1.06 | 0.19 | 1.00 | 0.97 |

| 0.48 | 1007127 | Round | BRS | 5/8-18UNF | 0.56 | 0.31 | 1.00 | 0.48 |

| 0.48 | 1006846*** | Round | STEEL | 5/8-18UNF | 0.56 | 0.13 | 1.00 | 0.417+ |

| 0.48 | 1007118 | Round | BRS | 5/8-18UNF | 0.81 | 0.31 | 1.00 | 0.73 |

| 0.48 | 1007276 | Round | SST | 5/8-24UNEF | 0.75 | 0.13 | 1.00 | 0.625+ |

| 0.48 | 1007279 | Hex | SST | 3/4-16UNF | 0.38 | 0.19 | 1.00 | 0.28 |

| 0.48 | 1000058** | Hex | STEEL | 3/4-16UNF | 0.50 | 0.13 | 0.88 | 0.41 |

| 0.48 | 1007225 | Hex | BRS | 3/4-16UNF | 0.88 | 0.25 | 1.00 | 0.78 |

| 0.48 | 1007228 | Hex | SST | 3/4-16UNF | 0.88 | 0.25 | 0.88 | 0.78 |

| 0.48 | 1007273 | Hex | SST | 3/4-16UNF | 1.06 | 0.19 | 1.00 | 0.97 |

| 0.49 | 60000389 | Hex | BRS | 5/8-18UNF | 0.50 | 0.13 | 0.88 | 0.42 |

| 0.49 | 60000138 | Hex | SST | 5/8-18UNF | 0.88 | 0.19 | 0.88 | 0.729+ |

| 0.49 | 60000317 | Hex | SST | 3/4-16UNF | 0.56 | 0.13 | 1.00 | 0.47 |

| 0.49 | 60000070 | Hex | SST | 3/4-16UNF | 1.06 | 0.19 | 1.00 | 0.97 |

| 0.63 | 60000410 | Hex | STEEL | 7/8-14UNF | 1.00 | 0.13 | 1.13 | 0.83+ |

| 0.63 | 60000373 | Hex | SST | 7/8-14UNF | 1.13 | 0.13 | 1.13 | 0.955+ |

| 0.63 | 60000008 | Hex | SST | 7/8-14UNF | 1.38 | 0.13 | 1.13 | 1.205+ |

| 0.63 | 60000375 | Round | STEEL | 7/8-14UNF | 1.88 | 0.13 | 1.25 | 1.705+ |

+ Fitting has a 1/16” weld projection not included in the “F” dimension shown. Consult factory for details.

* Tin plated brass

** This fitting is copper plated steel, normally furnished on finned tubular elements with palnut type locknuts standard. Gaskets are not furnished unless specified.

*** Nickel plated steel

Other fittings available, contact factory.

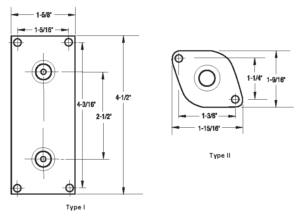

MOUNTING PLATES

MOUNTING PLATES

Mounting plates provide a simple, convenient means of holding elements in place in an airstream and other applications where the element is not immersed in a liquid. Stainless steel plates are mechanically pressed (staked) or tack welded to sheathed elements.

The mounting plates shown to the right are standard configurations for .475” diameter elements. Consult factory for other diameters and configurations.

| Heating Element Configuration |

Mounting Plate | |

| Type | Material | |

| 2-1/2” C-C U-Bent | I | Stainless |

| Straight or Two-Pass | II | Stainless |

terminal assembly options

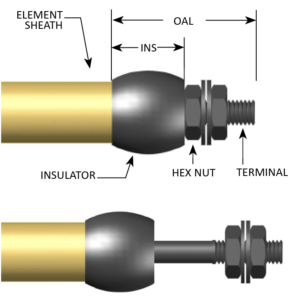

Terminal # 1

Threaded Terminal (standard)

| Description: Stainless steel stud with threaded length Optional: Insulators available in silicone rubber (std) or optional mica or ceramic where available Use: For lead attachment in the field. 600V rating |

|

| Thread Sizes* | OAL Standard | INS Standard (Insulator Dim) |

| 6-32 | 1” | 0.50” |

| 8-32 | ||

| 10-32 | ||

| 1/4-20 |

* 6-32 thread is standard for .250 and .260

Element Diameters, 10-32 thread is standard for all other Diameters.

Other thread size, INS and OAL lengths available upon request.

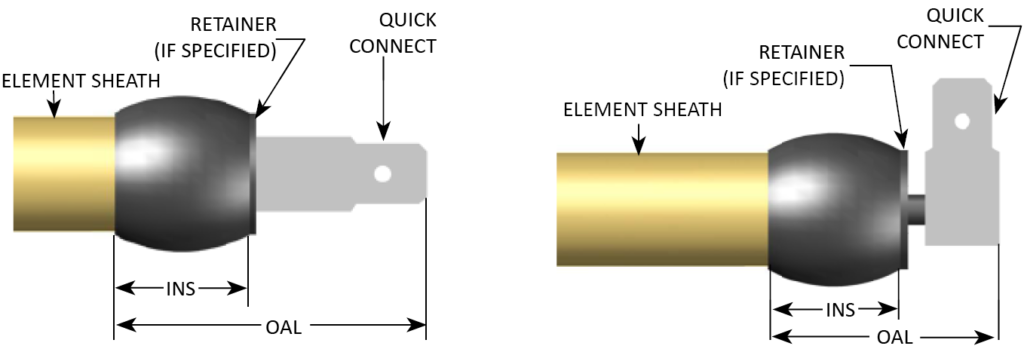

Terminal # 2

Quick Connect Terminal

|

Description: Optional: Use: |

|

| oltage Range |

OAL Standard (Straight terminal) |

OAL Standard (90 Deg terminal) |

INS Standard (Insulator Dim) |

| 0-250V | 0.75” | 0.813” | 0.25 |

| 251-600V | 1” | 1.063” | 0.5 |

Terminal # 3

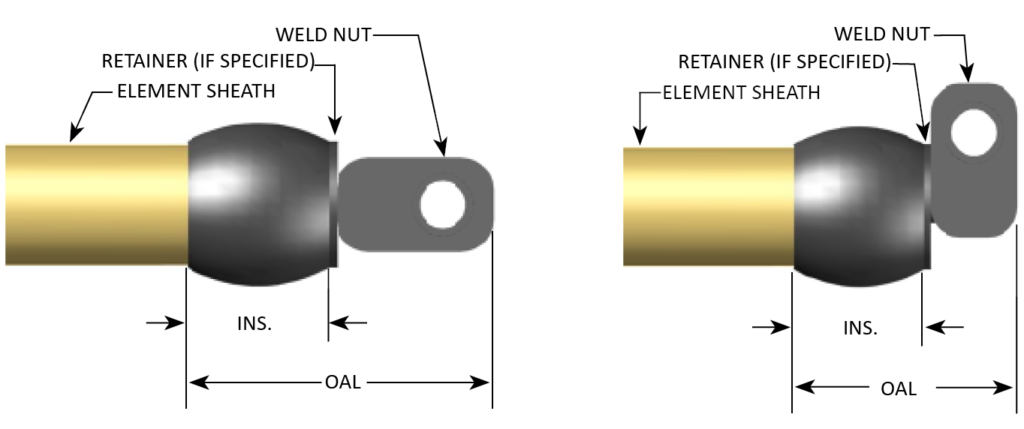

Weld NutDescription: Use: |

|

| Voltage Range |

OAL Standard (Straight terminal) |

OAL Standard (90 Deg terminal) |

INS Standard (Insulator Dim) |

| 0-250V | 0.813” | 0.563” | 0.25 |

| 251-600V | 1.063” | 0.813” | 0.5 |

Terminal #4

Neoprene Insulated LeadsDescription: Use: |

PVC Insulated LeadsDescription: Use: |

Silicone Insulated Leads with Glass Braid (SRG)Description: Use: |

|

Type TGGT LeadsDescription: Use: Mica Insulated Leads with Glass Braid (MGT)Description: Use: |

| Standard Supplied Wire Gauge | Limit Amps |

| 18 | 10 |

| 16 | 15 |

| 14 | 20 |

| 12 | 30 |

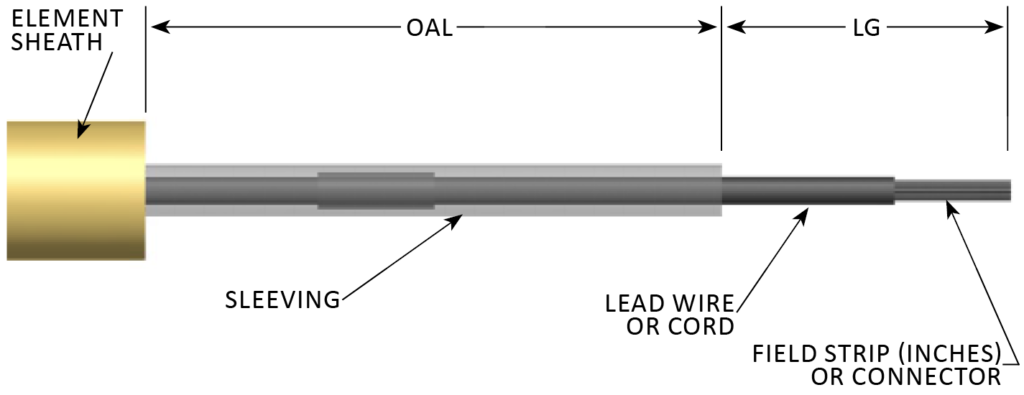

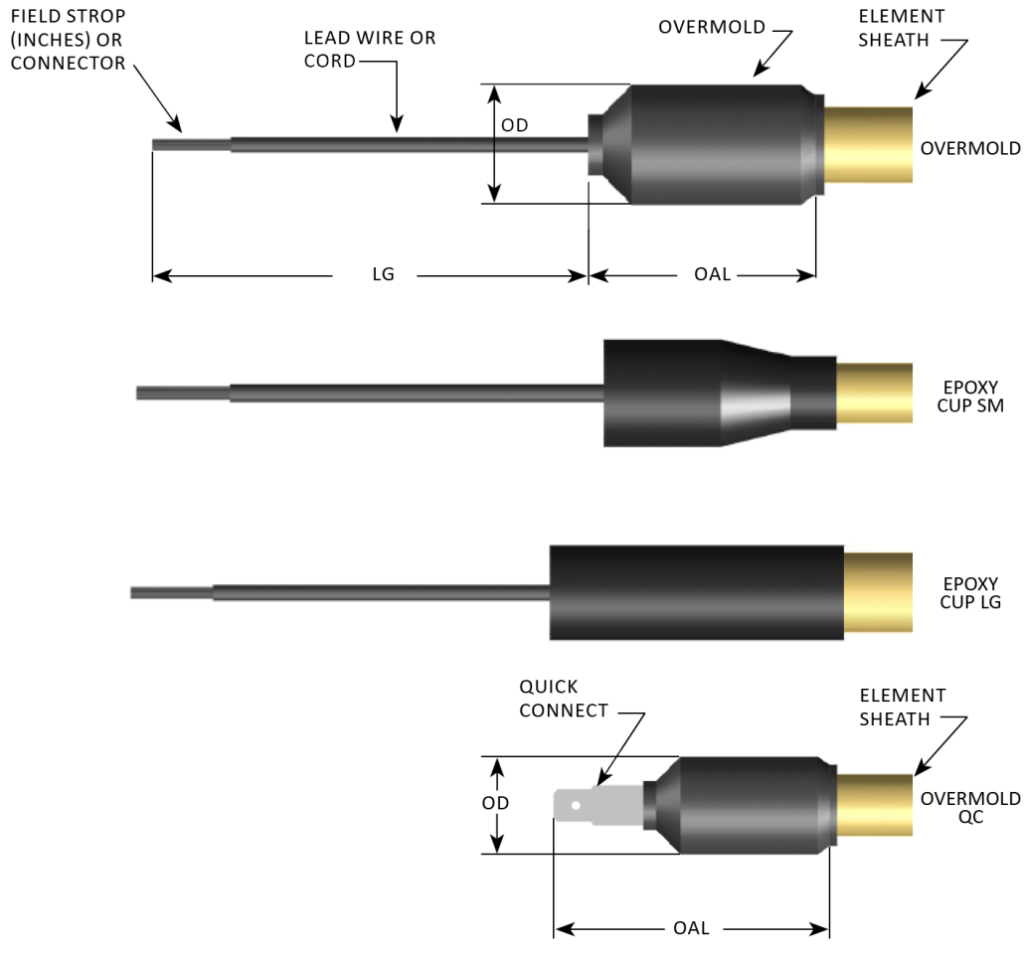

terminal # 5

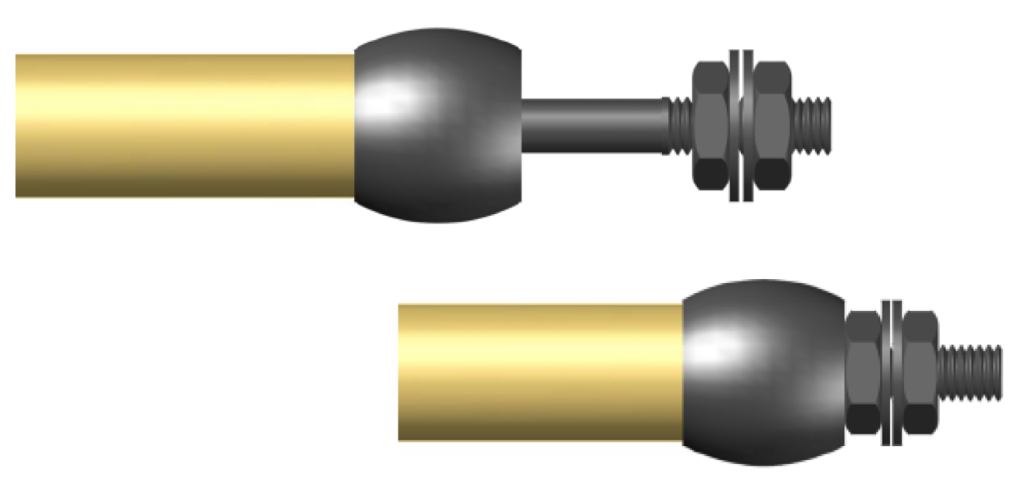

Defrost TerminalDescription: OR Epoxy Filled Metal Cup TerminalDescription: Use: |

|

| Type | Material | Type | Element Sizes | OD | OAL | Location | Description |

| Overmold QC | Neoprene | One-Pass | 0.250 – 0.315 | 0.4375 | 1.0625 | Moist | T Series |

| Epoxy Cup SM | Epoxy/Metal | One-Pass | 0.315 | 0.5625 | 1.25 | Wet | Blank Series |

| Epoxy Cup LG | Epoxy/Metal | One-Pass | 0.475 | 0.5625 | 1.75 | Wet | Blank Series |

| Overmold | Neoprene | One-Pass | 0.250 – 0.375 | 0.4375 | 1.75 | Wet | W Series |

| Overmold | Neoprene | One-Pass | 0.430 – 0.490 | 0.75 | 1.75 | Wet | W Series* |

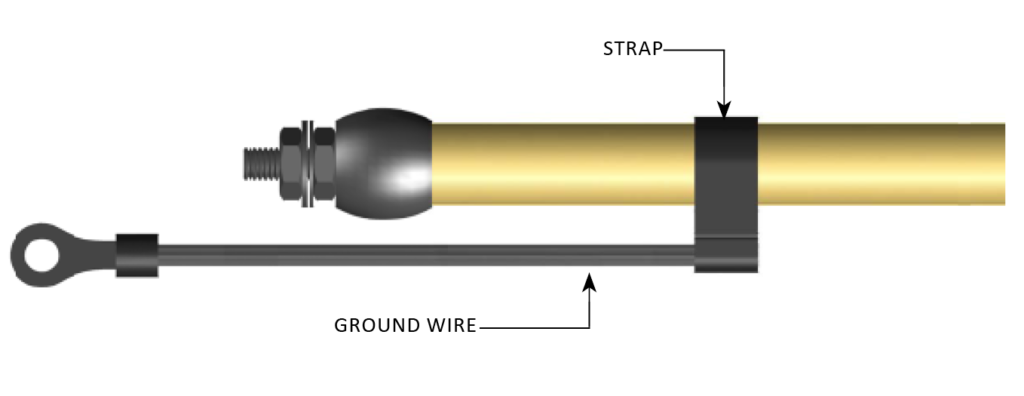

Grounding Strap (Optional)

|

Description: Use: |

|

End Seal Options

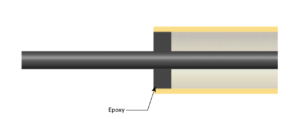

End Seal #1:Epoxy BarrierDescription: Use: |

|

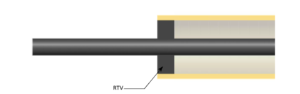

End Seal #2:RTV BarrierDescription: Use: |

|

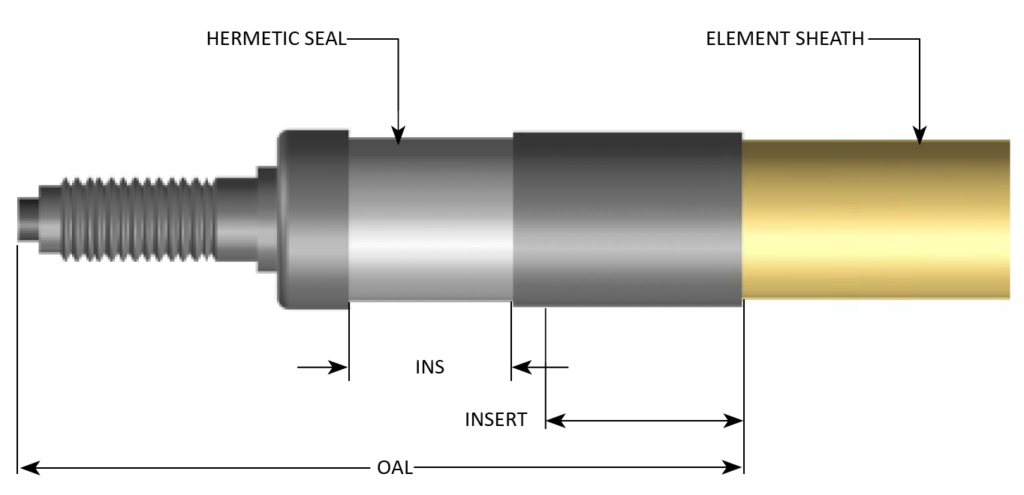

End Seal #3:Hermetic SealDescription: Use: Element Sheath: |

|

| Element Sheath Diameter | INS Standard (Integral Ceramic Insulator Dim) | OAL Standard |

| 0.430 | 0.5 | 2.125” |

| 0.475 | 0.5 | 2.125” |

| Alternate element sheath diameters available upon request. | ||

Insulator Options

Insulator #1:Silicone Rubber (standard)Description: |

|

Insulator #2:MicaDescription: Applications where terminal temperatures do not exceed 900oF. 1/4” thick insulation furnished up to 250V; 1/2” thick up to 600V. |

|

End Seal #3:Insulator #3:CeramicDescription: |

|