AIR DUCT HEATERS

Air Duct Heaters are designed to heat moving air and gases up to 1200° F. These heaters are suited to handle many industrial applications. Process air duct heaters are installed into ducts and ovens for applications such as: air drying, curing paint and coatings, chemical and food processing and metal finishing.

OPTIONS

- Moisture or explosion proof wiring enclosure

- Gas tight construction on elements to flange

- High limit thermocouple attached to sheath of element

- Special ratings & sizes

- Spare elements

- All stainless construction for high temperature or corrosive gases

SERIES DL TUBULAR

Air Duct Heaters feature stainless steel elements, stainless steel element support, painted steel support rods & flange, NEMA 1 terminal enclosure, and replaceable element design. Low temperature (500°F max.)

SERIES DM TUBULAR

Air Duct Heaters feature Incoloy 840 elements, stainless steel element support, stainless steel support rods, painted steel flange, NEMA 1 terminal enclosure, and are designed with replaceable elements.

SERIES DH TUBULAR

Air Duct Heaters feature Incoloy 840 elements, stainless steel element support, stainless steel support rods, 3-1/2″ high temperature insulation below flange, NEMA 1 terminal enclosure, and are designed with replaceable elements.

SERIES ILD IN-LINE TUBULAR

Air Duct Heaters feature Incoloy 840 elements, painted steel frame, NEMA 1 terminal enclosure, and are designed with replaceable elements.

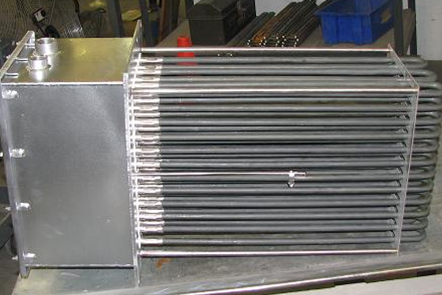

FINNED TUBULAR PROCESS AIR HEATERS

Finned Tubular Process Air Heaters are designed to provide air temperatures to 500°F (260°C). Typical applications include comfort heating, drying, fruit and produce ripening rooms, forced air dryers, recirculating ovens, heating of cryogenic exhaust gas and other air heating applications with a maximum sheath temperature of 850°F (455°C)

watt density per application

- 90 Watts Per Square Inch – For heating clean water only in commercial and/or residential applications. Element life is sacrificed in favor of a low initial heater cost.

- 60 and 45 Watts Per Square Inch – Industrial water heating – many aqueous solutions which are compatible with steel and Incoloy.

- 23 and 20 Watts Per Square Inch – For heat transfer oil, cleaners, high temperature air and gas heating.

- 15 and 12 Watts Per Square Inch For lubricating oils, medium viscosity oils, high temperature air and gas heating.

- 8 and 6 Watts Per Square Inch – For #5 and #6 fuel oil heating, viscous materials, raw crude oil, residual oils, high temperature air and gas heating.