CHART RECORDERS

PAPERLESS RECORDERS

The number of direct analog inputs varies by model with the PR10/20/30 offering up to 6, 24 and 48 respectively with a 100ms total sample rate for all analog and digital inputs. All input channels freely configurable and named to suit your process requirements.

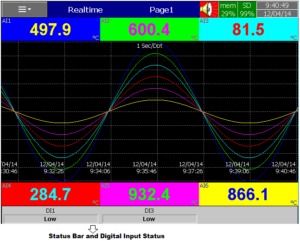

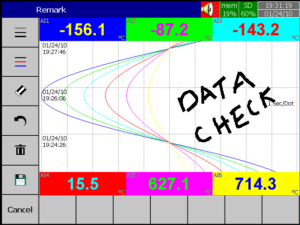

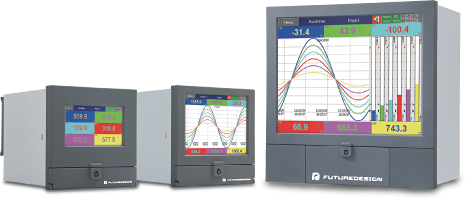

The PR Series high resolution 4.3″, 5.6″ and 12.1″ touch displays provide multiple display formats,easy touch navigation and support for 19-languages allowing ease of use and setup. In addition, freehand messaging is supported with a stylus of finger directly on the touch screen that may be saved as part of the data log file.

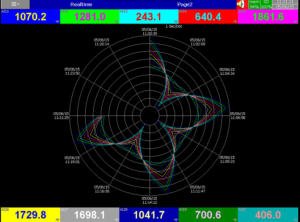

PR Series Paperless Recorders Screen Views

Applications:

- AMS2750E Heat Treating Requirements

- Ovens – Furnaces – Kilns

- Environmental Chambers

- Boilers

- Sterilizers / Autoclaves

- Power Generation Variables

- Flow Applications / Totalizers

- Water / Waste Water Flow

- Test & Measurement Applications

features:

- 4.3″, 5.6″ & 12.1″ Touchscreen

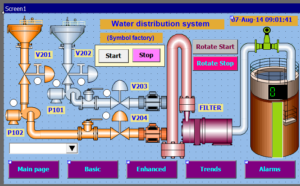

- Custom Graphic Display Views

- Process Control PID Module with Profile

- Scan Rate: 100ms all Analog Inputs (48 max),

Digital Inputs & External Channels (96 max) - Batch Functions (Data Log)

- Web Server / Email on Alarm

- Timers & Counters

- Security / Operator Audit Trail

- PID Control Loops with Profiling (up to 4 or 8 PID modules PR10/20-PR30)

- Digital Inputs / High Frequency Pulse

- Print Directly to Printers; Local, Network & pdf

- Free Hand Messaging on Touch Screen

- Circle Chart View (PR30 & all in PC Software)

PAPERLESS RECORDERS

The PR Paperless Recorder models PR10, PR20 and PR30 provide intuitive operation through 4.3”, 5.6” and 12.1” TFT touch screens.

The number of direct analog inputs varies by model with the PR10/20/30 offering up to 6, 24 and 48 respectively with a 100ms total sample rate for all analog and digital inputs. All input channels freely configurable and named to suit your process requirements.

The PR Series high resolution 4.3″, 5.6″ and 12.1″ touch displays provide multiple display formats,easy touch navigation and support for 19-languages allowing ease of use and setup. In addition, freehand messaging is supported with a stylus of finger directly on the touch screen that may be saved as part of the data log file.

The VR Series Paperless Recorders, upgraded to a larger 6.4″ TFT display is the most advanced and offers the largest display of an 100mm style paperless recorder available. With 16MB on-board ROM and reliable low cost Compact Flash (CF) cards the VR Series are ideal for monitoring, recording and evaluation processes in a variety of applications. [512MB CF card standard, 1GB & 2 GB optional]

The VR Series offers modular design allowing up to 18 analog inputs or a mix of analog & digital I/O utilizing plug & play I/O cards.

The standard VR Series includes 6 Timer functions and with the Extended Software now standard (Math) system now includes 6 counters, an additional 18 derived channels configurable with Math Expressions and/or as Totalizers & High Security with CFR-21 Part 11 type features. With up to 18 analog inputs and 18 Derived channels for Math & other functions the VR 18 has potential for up to 36 channels!

VR18 and VR06 Paperless Recorders:

VR18 allows up to 18 Analog Inputs

VR06 allows up to 6 Analog Inputs

The VR Series 6.4” TFT high resolution [640 x 480] display allows multiple display formats and easy-to-access keys make monitoring and setup extremely easy. Data can be stored in flash ROM, compact flash card or on a PC via RS485 or Ethernet options.