Custom Specialty Heaters

Specialty Flanged Inline Heaters

High-temperature & high-pressure custom process heating solutions for precise and durable performance.

Growing demand for efficient engines with reduced emissions and renewable forms of energy has increased the need for testing and research using high-temperature and high-pressure gas streams. Tutco SureHeat Specialty Flanged Inline (SFI) Heaters deliver safe, precise, and durable performance in a wide-range of extremely demanding high-temperature, high-pressure and low-flow applications. SFI heaters are customized electric heating solutions manufactured to meet your specifications.

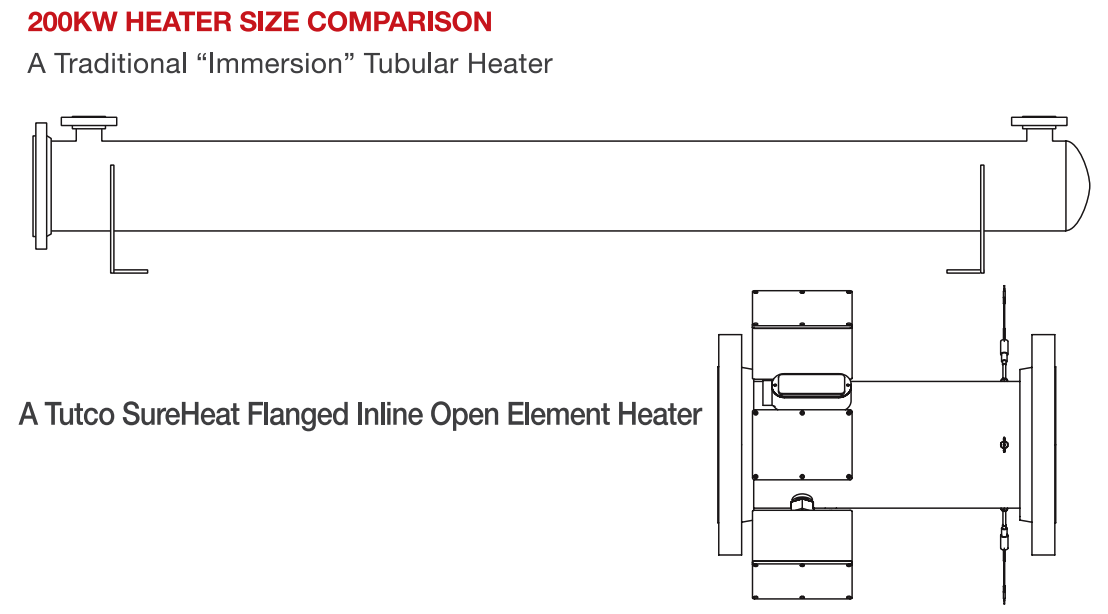

Tutco SureHeat Specialty Flanged Inline (SFI) Heaters deliver safe, precise, and durable performance in a wide-range of extremely demanding high-temperature, high-pressure and low-flow applications. SFI heaters are customized electric heating solutions manufactured to meet your specifications. Specialty Flanged Inline (SFI) inline heaters offer superior performance over conventional sheathed (“tubular” or “immersion”) style heaters because they are designed specifically for air and inert gas applications. Our proprietary SERPENTINE™ technology facilitates a very high power density and compact overall design. SFI heaters can be as much as 8-12X smaller than equivalent tubular/immersion designs. With this advantage, installations become smaller, lighter, and more cost effective, with a faster heat-up and cool-down time. Whether for a research test stand, factory production line, or key component in a product or system, our Specialty Flanged Inline heater is the right heater solution for the job.

COMBUSTION RESEARCH

FUEL CELL R&D

POLLUTION CONTROL

RENEWABLE ENERGY

System Overview

An SFI System consists of an open element electric heater plus a control cabinet to ensure accurate temperature control and safe operation.

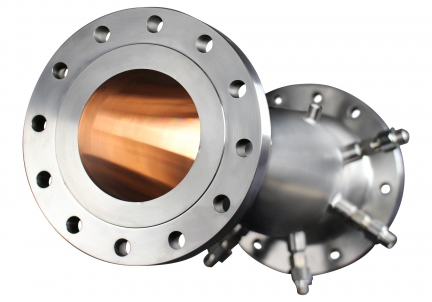

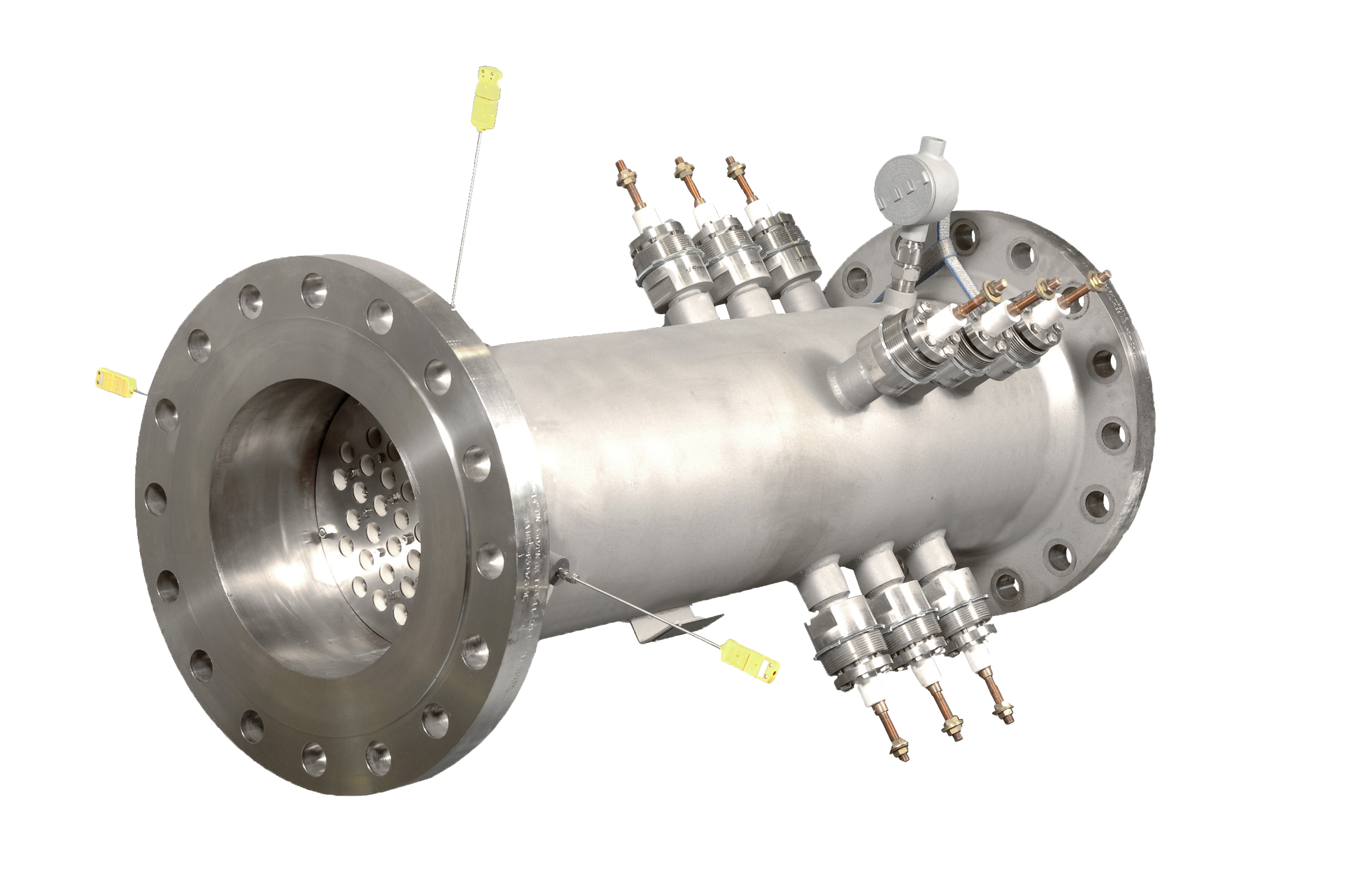

The Heater

An SFI heater consists of a metal housing and the heating element assembly installed inside the housing. The metal housing is a round pipe with flanges for connecting to the customer’s piping and fittings for the power supply feed-throughs and control instrumentation. It is custom engineered to meet the unique temperature, pressure, and mass flow rate requirements for the application. The diameter is determined by how large the heating element needs to be to meet the heat transfer demand while maintaining low pressure drop. Wall thickness, flange specifications, and material of construction are all established by ASME design principles for pressure vessels (Section VIII, Division 1).

The Control Cabinet

Tutco provides custom control cabinets designed to work with our Serpentine elements and are guaranteed to work safely with our heater. Other control devices may not offer the responsiveness required to control Serpentine elements and are not guaranteed by Tutco SureHeat. Control cabinets include a phase-angle fired SCR power controller, PID-Based digitial temerature controller, and a 4 input OTP limit circuit.

Heater Types

SFI-HP – High Pressure Models

High Pressure models are designed for use with high pressure air sources (> 50 psi, 3.5 Bar), and are constructed of heating elements aligned with the airflow. SFI-HP models can produce air/gas temperatures to 1652°F (900°C) or higher in custom designs.

SFI-LP Low Pressure

Low Pressure models are designed for use with low pressure air sources like regenerative blowers (< 50 psi, 3.5 Bar) and are constructed of low-restriction crossflow elements. SFI-LP models can produce air/gas temperatures to 1475°F (800°C).

Standard Design SFI Specifications

- Maximum Static Pressure…………………………….600psi (41.37bar)

- Maximum Inlet Temperature……………………………….900°F (482°C)

- Standard Outlet Temperatures………………………..1652°F (900°C)

- Temperature Control……………………………………………+/- 2°F (+/-1°C)

- Ramp time………………………………………………………..50°C per second

Custom Design SFI Specifications

- Maximum Static Pressure…………………………….3000 PSI (207 Bar)

- Maximum Inlet Temperature……………………………….900°F (482°C)

- Standard Outlet Temperatures………………………..1922°F (1050°C)

- Temperature Control……………………………………………+/- 2°F (+/-1°C)

- Ramp time………………………………………………………..100°C per second

- Maximum Power Rating……………………………….1 MW and Higher

Inline Duct Heaters

High Temperature Performance at Higher Flow and Low Air Pressures

TUTCO SureHeat Inline Electric Duct Heaters provide compact, fast response heating for a multitude of industrial and research applications where gas pressure is ≤ 10 PSI (.7 Bar) and temperatures up to 1475°F (800 °C). Tutco SureHeat’s proprietary Serpentine™ heating elements deliver the industry’s highest watt density ensuring a compact installation, low weight, and fast ramp and response time. Factory preassembled with flanged connections and a round, heavy duty duct housing assures a quick, uncomplicated installation. A complete system includes a power supply control panel assuring safe, reliable operations.

Contact us to share your required specifications with our applications engineers. We look forward to helping determine the best product or custom solution to meet your air heater requirements.