<- Flow Torch Home

Flow Torch 400s ->

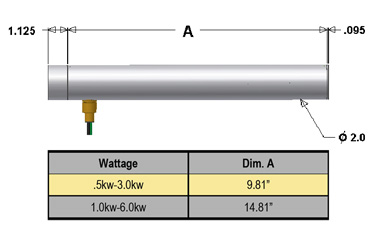

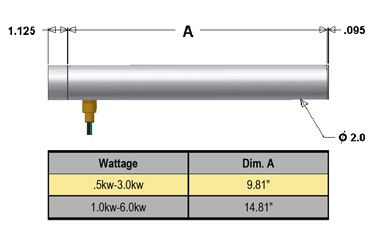

The Flow Torch 200 is capable of operation with airflows of up to 115 SCFM and a maximum operating pressure of 120 PSIG*. Maximum output temperature is 900 °F (482 °C). Standard power of 0.5 kW to 6 kW is available in 500 watt increments.

The Flow Torch 200 offers reliable, long-life performance and reduced operational costs. Applications include hot air curtains, air drying, baking, chemical processing, dehumidification, laminating, web drying, textile applications, ink drying, paint baking/drying, plastic curing, metallization, exhaust gas heating, hopper drying and sterilization. Optional equipment includes thermocouple and thermocouple fittings, stainless steel inlet and outlet reducers for hose or pipe. Control Panels are also available to provide precise temperature regulation.

Regenerative Blowers available with complete systems.

All Flow Torch Heaters are UL recognized components under UL file number E365755.

* Note: minor leakage through stranded leads

| MAX WATT | MAX INLET | MAX EXHAUST | MIN SCFM | MAX SCFM | PSIG* |

|---|---|---|---|---|---|

| 6000 W | 250 °F | 900 °F | 10 | 115 | 120 |

Mounting.= Horizontal / Vertical

Heater Body = Stainless Steel

Inlet Fittings = Stainless Steel

Exhaust Fittings = Stainless Stee

Applications include:

- Hot Air Curtains

- Air Drying

- Baking

- Chemical Processing

- Dehumidification

- Laminating

- Web Drying

- Textile Applications

- Ink Drying

- Paint Baking/Drying

- Plastic Curing

- Metallization

- Exhaust Gas Heating

- Hopper Drying

- Sterilization

Control Panels are also available to provide precise temperature regulation.

Firesleeve Accessory

This self-extinguishing thick-walled sleeve offers excellent thermal protection. Critical system components are protected from direct flame, high heat, and molten metal. Thermal insulation keeps hot lines hot and cold components cool. Provides protection by reducing the surface temperature of hot lines. Extends service life of assemblies and provides personnel protection.

- High-quality, texturized fiberglass, coated with a self-extinguishing silicone polymer

- Meets UL 94 HB Requirements

- Meets UL 94V-0 Requirements

- Continuous Working Temperature: 500 °F / 260 °C

- Short Term Temperature: 2200 °F / 1200 °C

- Will not melt, burn, or support combustion

- Does not emit toxic smoke

- Resistant to hydraulic fluids, fuels, lubricating oil, and water

- For use in industrial applications

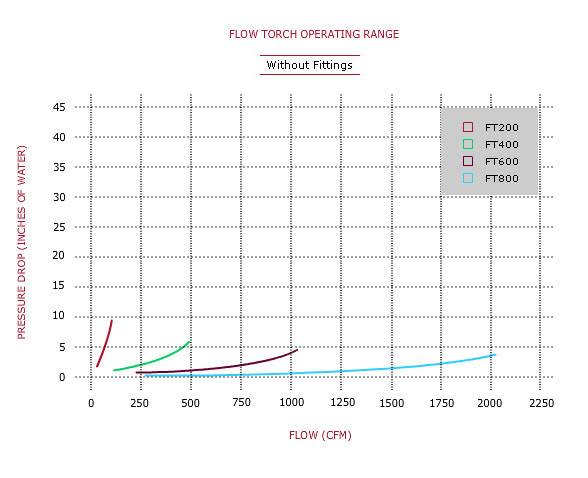

Pressure drop Chart (without fittings)

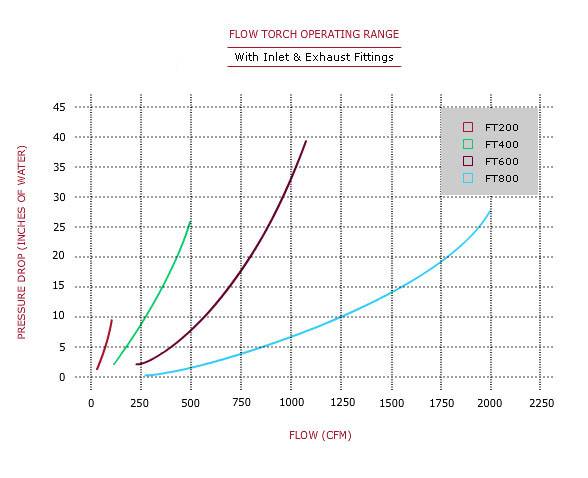

Pressure drop chart (with fittings)