Staggered Blade Beside The Press SPECS.

| Model# | Motor HP | Chamber Size | Thru-Put (lbs/hr) |

| SG-2324 | 8.4 | 9.4X9 | 250 |

| SG-2336 | 11.5 | 14.2X9 | 300 |

| SG-2348 | 16.9 | 19X9 | 400 |

DESCRIPTION

.

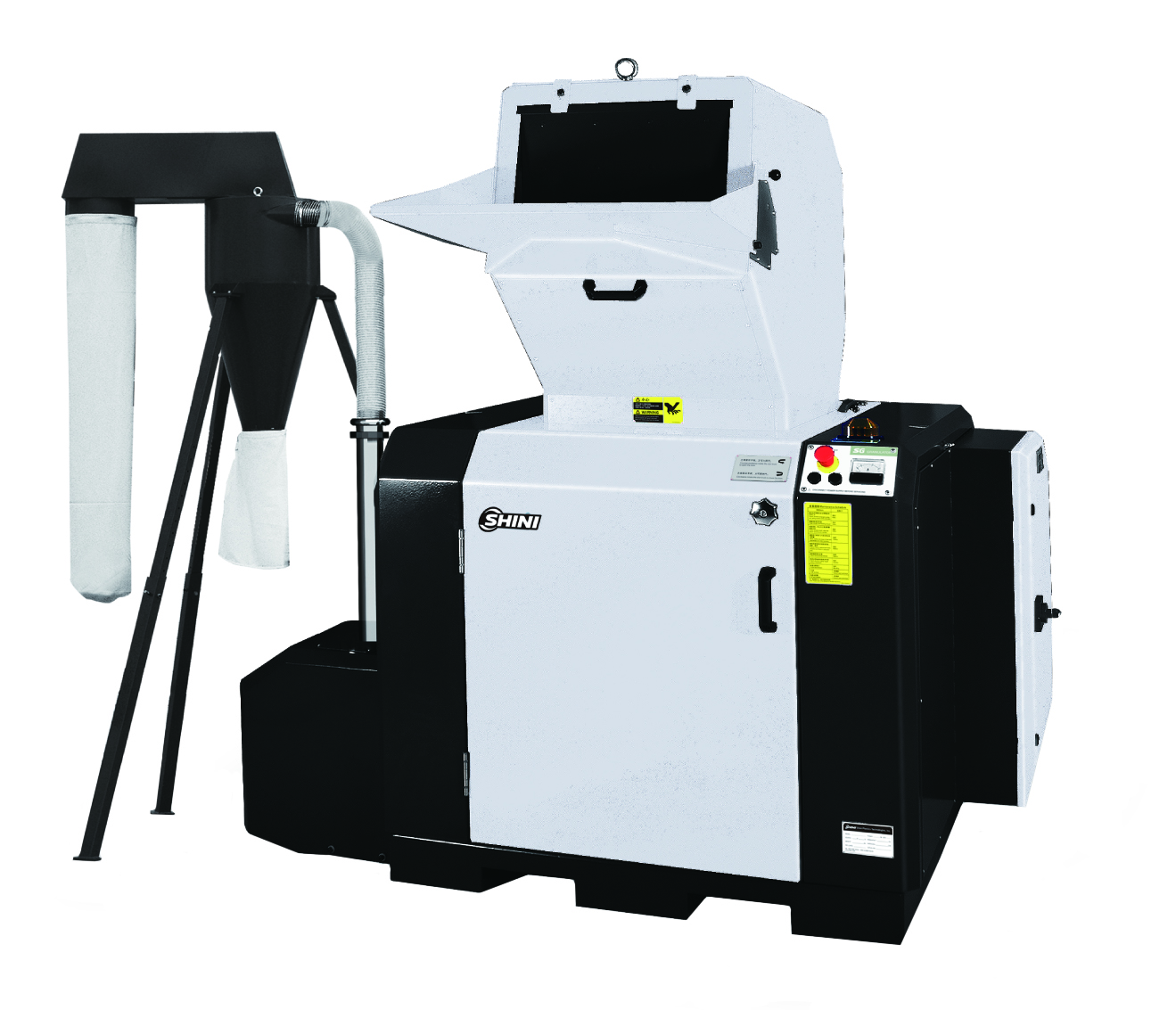

The Shini USA central staggered blade beside-the-press granulators are available in 460 or 230 volt and use a unique blade cutting design that results in well-proportioned granules and minimizes dust.

Each central staggered blade granulator allows for easy accessibility to parts for cleaning and maintenance. The staggered blade granulators are operator-friendly and safe, ensuring excellent performance. These beside-the-press granulators are ideal for grinding spruces, runners and rejected parts.

solid rotor staggered blade SPECS.

| Model # | Motor HP | Chamber Size (in) | Thru-Put (lbs/hr) |

| SG-1635HN | 4 | 13.8X6.3 | 170 |

| SG-2042NH | 5.5 | 7.9X16.5 | 200 |

OPEN ROTOR SCISSOR CUT SPECS.

| Model # | Motor HP | Chamber size(in) | Thru-Put (lbs/hr) |

| SG-2042NH | 5.5 | 16.5X7.9 | 170 |

DESCRIPTION

Each of our low-speed granulators comes equipped with D2 steel cassette knives, which creates well-proportioned granules that minimize dust. Additionally, these blades can be replaced easily and economically, eliminating additional re-sharpening costs.

Open Rotor/Scissor Cut Grinders

Open rotor grinders are designed for less dense, or “airy,” parts such as bottles, bottle closures, thin wall housings, thin extrusions and film.

Solid Rotor/Staggered Blade Grinders

The solid rotors are meant for heavier parts and those that have thick profiles. These rotors are designed to bounce the parts and “nibble” at them so as not to stall the grinder.

CENTRAL ROTOR STAGGERED KNIFE SPECS.

| Model # | Motor Hp | Chamber Size | Thru-Put (lbs)/hr |

| SG-3060H | 25 | 12×24 | 250 |

central open rotor scissor cut SPECS.

| Model # | Motor Hp | Chamber Size | Thru-Put (lbs)/hr |

| SG-360HP | 25 | 12X24 | 600 |

| SG-3650P | 25 | 14X20 | 1300 |

| SG-3675P | 40 | 14X29 | 1904 |

| SG-4360H | 55 | 14X24 | 2000 |

| SG-4390H | 68 | 17X35 | 2500 |

| SG-5080P | 50 | 19X31 | 2425 |

| SG-50110P | 60 | 19X43 | 3300 |

| SG-7090 | 100 | 27X35 | 5000 |

| SG-70120 | 120 | 27X47 | 550 |

DESCRIPTION

The Shini USA central open rotor scissor cut granulators are both safe and easy to operate. Each central open rotor granulator allows for easy accessibility to parts for cleaning and maintenance, while its unique design helps minimize dust.

In addition to reducing dust, these central scissor cut granulators also help to minimize noise pollution with a fully enclosed design featuring sound-proofing.

All of our central open rotor granulators are available in 460 or 230 volt machines and are ideal for use beside the press to grind sprues, runners and rejected parts.