Heat Exchangers

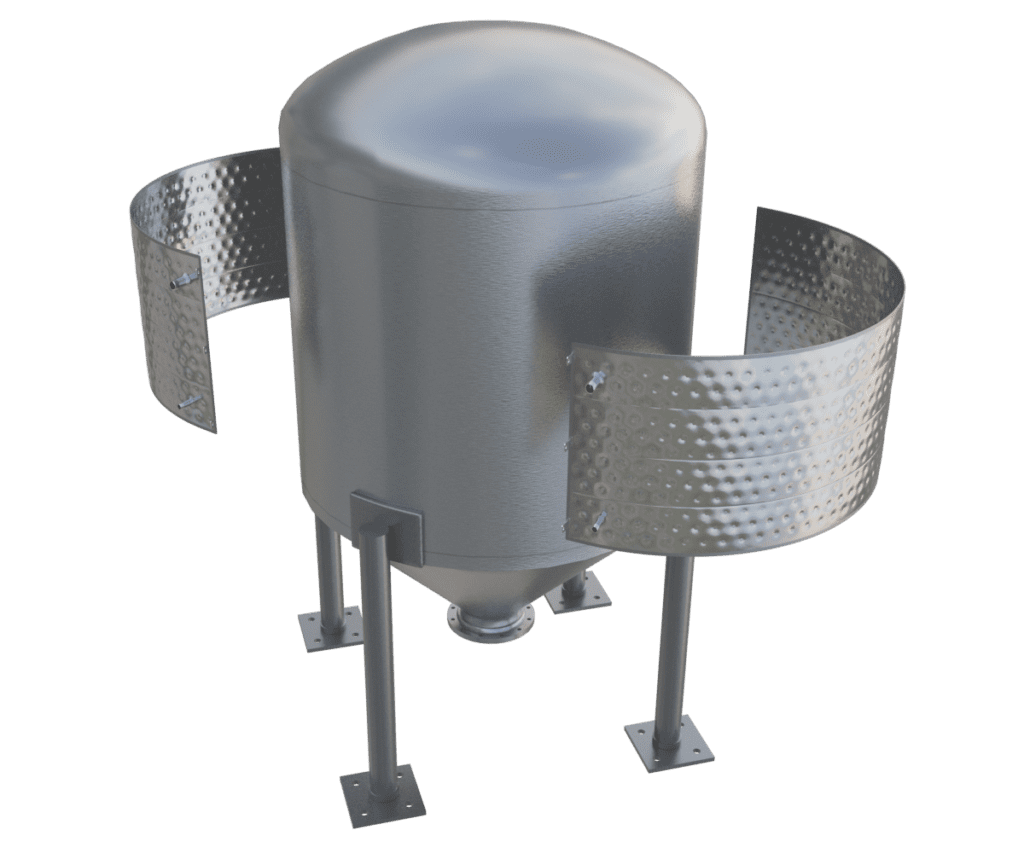

PILLOW PLATES HEAT EXCHANGERS

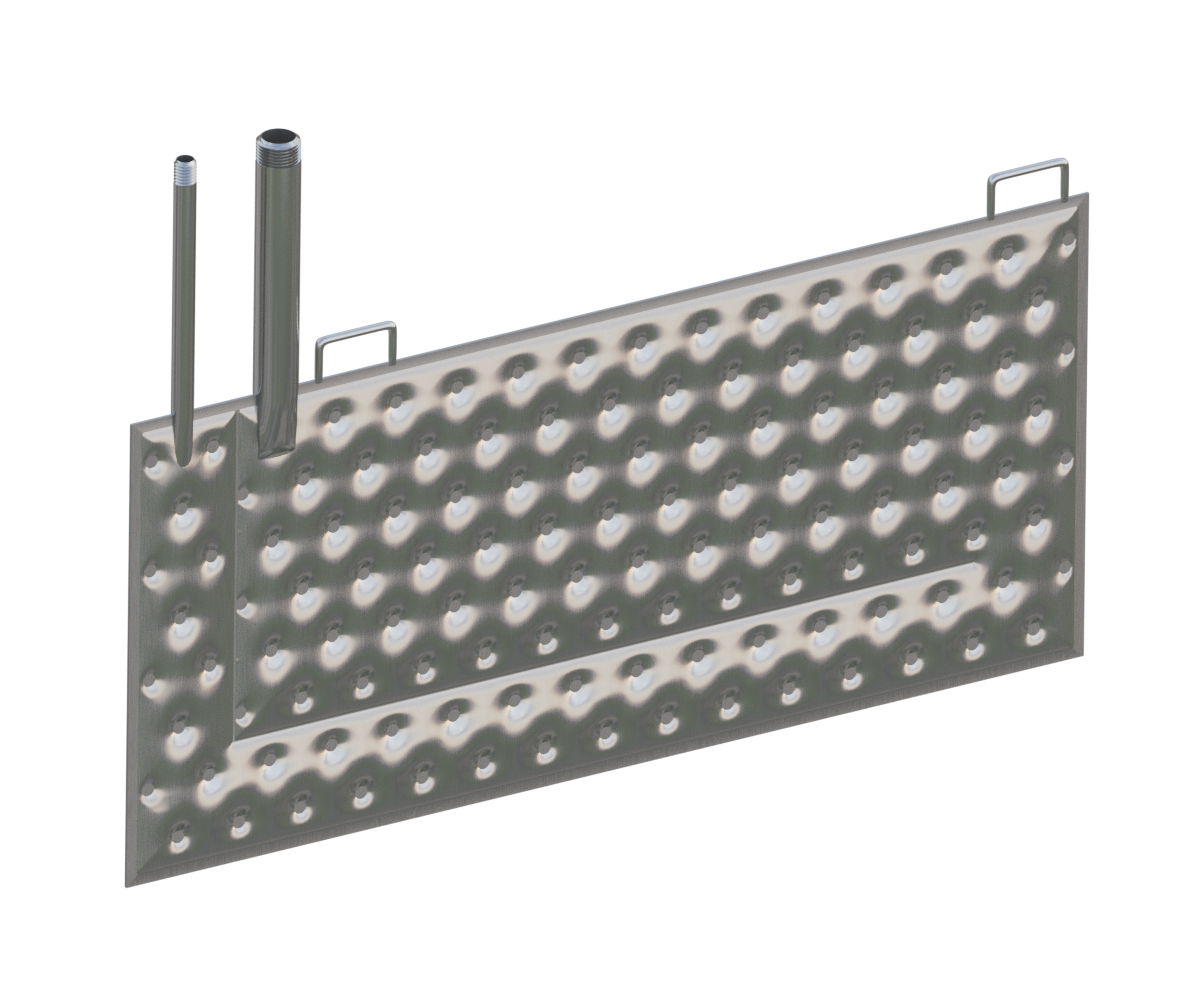

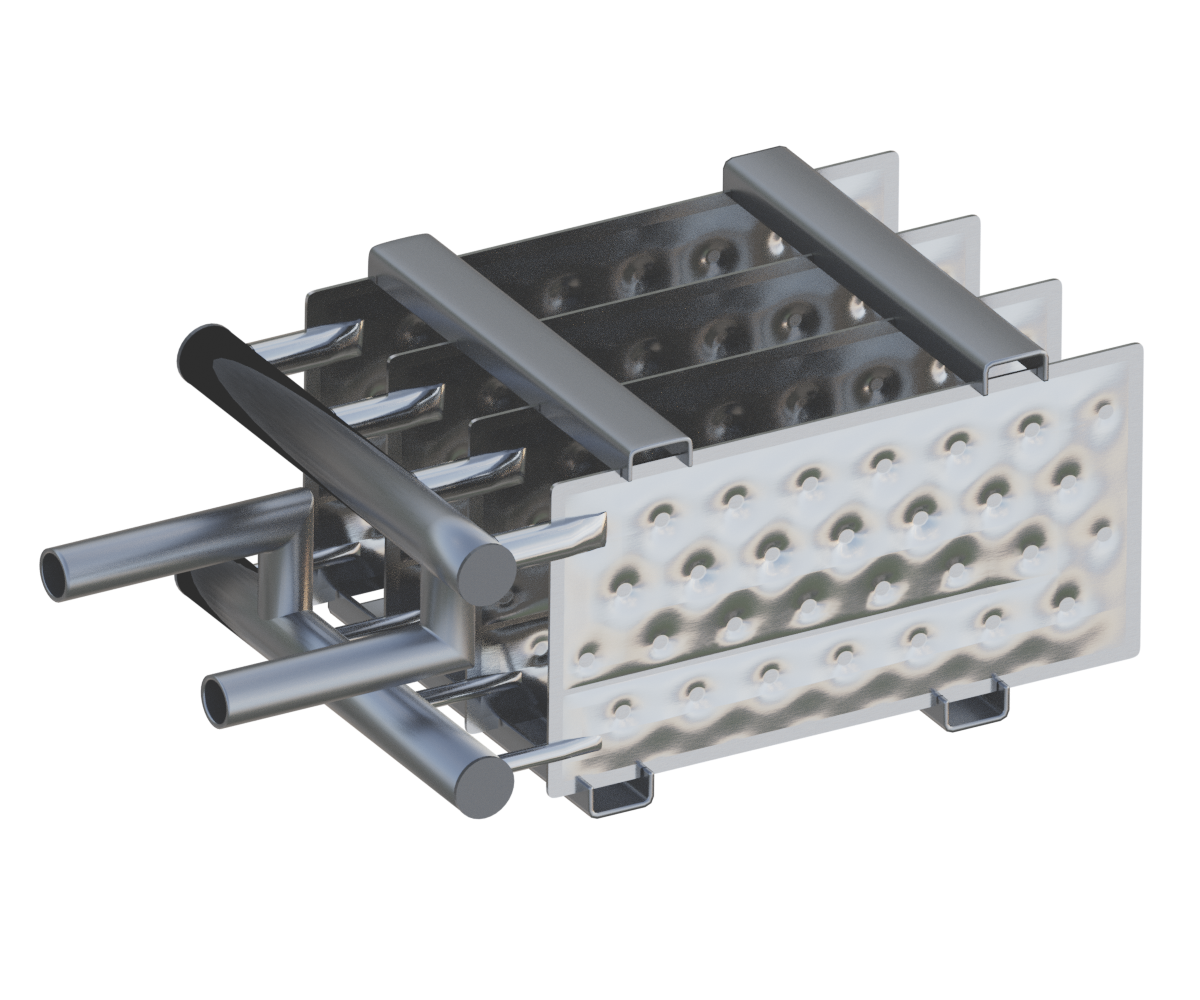

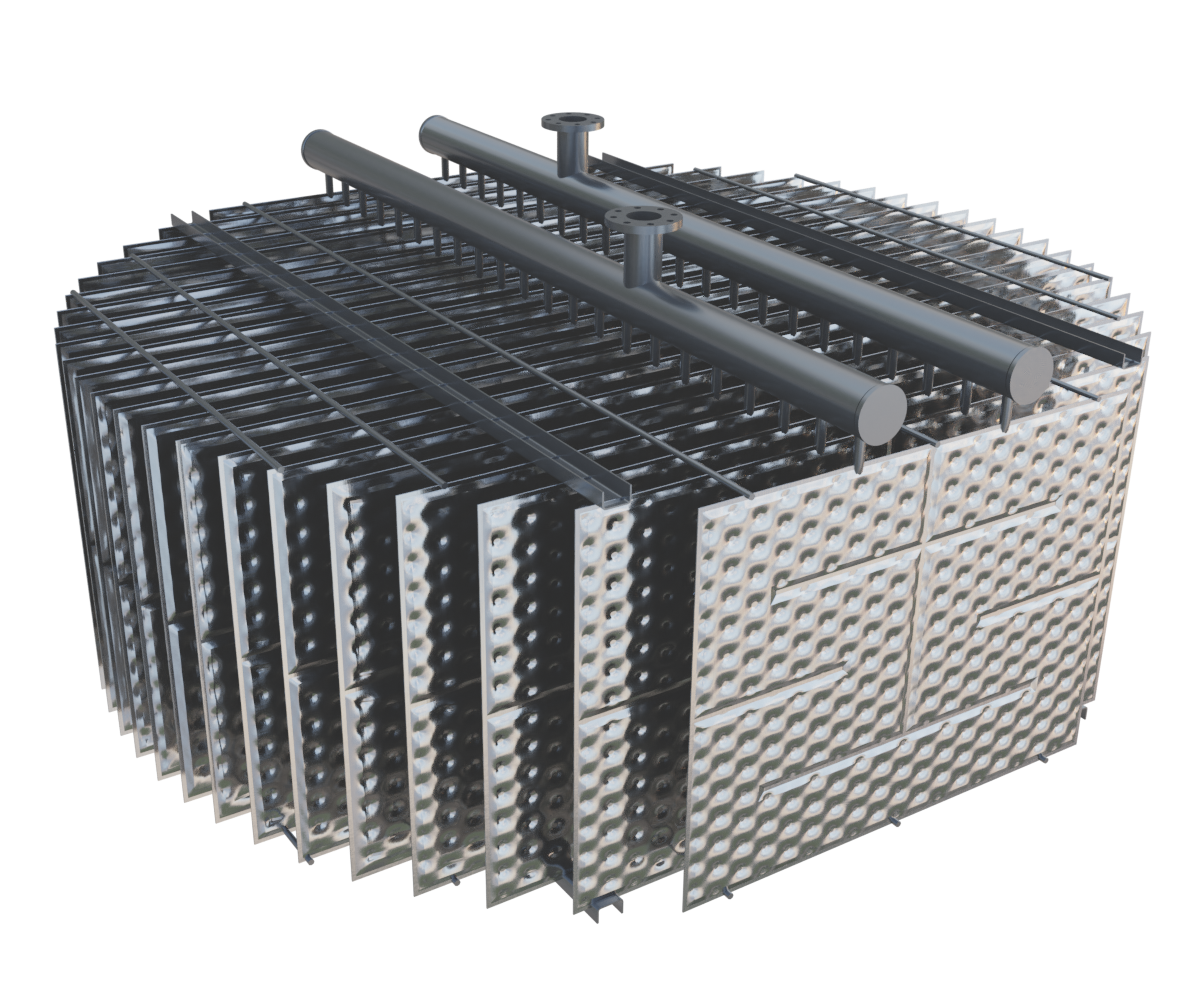

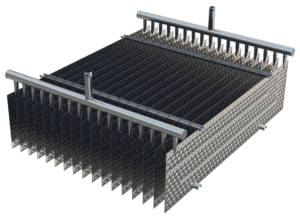

Pillow plates surfaces are a fully welded and inflated type heat exchangers that are manufactured by stacking two flat sheets of material and fuse welding them together with a strategically positioned welding pattern.

A typical welding pattern comprises of an outer seam weld defining the total pressure boundary of the plate and then an interior circle weld pattern specifically configured for the service type and performance requirements for a given application.

Once the welding is complete, the pillow plate will then be expanded by pressurizing the space between the two sheets. As pressure is increased, the gap between the unsupported portions of the plates will increase, creating the identifying “pillow” shaping of the plate.

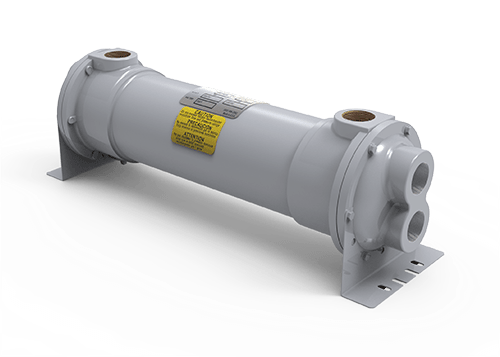

SHELL & TUBE HEAT EXCHANGERS

Southeast Thermal Systems supplies a wide range of high-quality shell and tube heat exchangers. These exchangers are one of the most commonly used and reliable types in industrial applications.

A shell and tube heat exchanger consists of a series of tubes—one set carries the hot fluid and the other carries the cold fluid. Heat is transferred between the fluids through the tube walls without them mixing. This design makes them ideal for handling high-pressure and high-temperature processes in industries such as chemical processing, power generation, HVAC, and oil and gas.

With multiple sizes, materials, and configurations available, we work closely with you to ensure the right fit for your specific thermal management needs.

A HOLISTIC APPROACH & STRATEGIC VISION FOR PROCESS SOLUTIONS