HEAT TRACE CABLE

Heat Cable Overview

Heat tracing is used to counteract the heat lost from process equipment and piping through its insulation. A heat tracing system is a group of process equipment and piping which is heat traced and controlled in a logical and economical manner.

There are many reasons for making up the heat loss of a system. With any heat loss, there is a corresponding drop in temperature. A drop in temperature of process fluids could result in solution precipitation, unacceptable viscosity increase or solidification of the product in the lines.

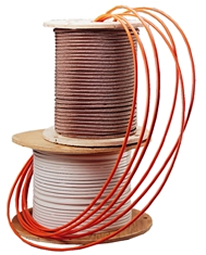

Constant Wattage Heating Cable (CWM)

CWM Constant Wattage heat trace cables are ideally suited for applications where a particular watt density is required at all times. Constant wattage cables are flexible and can be cut-to- length in the field. Although not suited for overlapping, its constant output makes it an ideal choice for higher temperature applications where higher watt densities are required. Chromalox CWM Constant Wattage heating cable is designed for use on 120 to 480V and withstands temperatures to 392 °F (200 °C). Equipped with a ground braid and optional FEP jacket, Chromalox Constand Wattage cables are third party tested and approved for use in harsh corrosive and hazardous area applications

Self Regulating Freeze Protection Cable (SRF)

Self Regulating Medium Temperature (SRM/E)

Self Regulating Low Temperature (SRL)

as well as certain corrosive industrial environments. SRL heating cable has a maximum maintenance temperature rating of 150°F (65°C).