applications for INFRARED HEATER FOR INDUSTRIAL HEATING

Click on any industry below for information

INDUSTRIAL HEATER LAMP APPLICATIONS

With high-quality standards and possessing state-of-the-art equipment, USHIO Oregon provides clean, instantaneous and precision controlled quartz infrared heater lamps (QIH). These high-efficiency lamps are able to transfer large amounts of heat while maintaining absolute controllability. Quartz tubes are best used for radiant applications that need instant on, instant off, such as heat sensitive materials that may have to linger in a heat source. USHIO’s quartz lamps are the best choice where precise high wattage density is necessary for high speed production processes while maintaining even heat controlled zones.

3D PRINTING

3D printing is an up and coming industry that requires precise substrate and environmental temperatures to obtain the best 3D print results. USHIO offers a wide array of custom design capabilities to fit your specific needs.

PAPER & TEXTILE DRYING

USHIO manufactures a wide array of infrared heater lamps with the ability to customize lamps to meet your specific needs. For paper and textile drying infrared heater lamps are well-suited for this application. Infrared heater lamps are used to dry the outer top surfaces of the material and penetrate deep into the material. This speeds up production time and saves on energy costs.

CURING

The USHIO (QIH) IR technology for curing is targeted to provide heat to specific areas where and when it is needed on demand. With the increasing popularity of powder coating curing applications, IR lamps apply even distribution of heat, resulting in polished and smooth surfaces.

The heat tunnel photo shown on the right is used to cure the coatings on wood furniture.

SOLAR SIMULATION

The USHIO (QIH) IR lamps are used in the solar simulation industry to mimic the sun’s spectral output in the IR region. The combination of visible light and IR light allows research of the complete affect of the sun on materials and testing of solar panel efficiencies.

specialty lamps

USHIO has engineering expertise to meet specialized requirements for custom products. We regularly produce specialized lamps in small quantities with short lead times to meet customer specific goals. Capabilities:

- Quartz Length 180 – 1600mm

- Quartz Tube Diameter (O.D.) 6 – 14mm

- Quartz Bending Radius 20 -250mm

- Color Temperature 1600 – 3200K

- Voltage Any, Wattage 12,000W Max*, Amperes 25A Max*

- Standard Coil, Filament Structure Segmented Coil, Wave Coil

BLOW MOLDING

The bottle blow molding industry extensively uses infrared heater lamps for plastic bottle molding. Being able to precisely control the temperature of the plastics allows a consistent plastic bottle to be formed.

GRAPHIC ARTS

The USHIO graphic art lamps are ideal for drying ink for graphic arts and silkscreen presses when printing on surfaces such as paper or textiles. With short and medium wavelengths, with wattages ranging from 375W to 6000W and the flexibility to customize lamps, USHIO’s graphic art lamps are repeatedly chosen for their quality.

SCIENTIFIC & MEDICAL

(QIH) IR lamps are an important component used in the Scientific and Medical industries. The controlled heating available with the IR heater lamps allow these lamps to be used to accurately and instantaneously control the temperature of the surrounding environment. USHIO provides an array of different power levels, different geometries and a wide range of color temperatures to fit your specific heating needs. The IR lamps are used in applications such as infant environment warming, heat therapy for aching muscles, spa and sauna heating and environmental control for laboratory experiments.

led chips

USHIO is a high quality solutions provider in the field of industrial LED’s and photo sensors. As a solutions provider, USHIO offers all wavelengths from UVC to visible and even into the infrared spectrum with available wavelengths between 270 and 1550nm. An extensive range of package styles are also available including SMD, high power TOP, super beam, ultra high power arrays, stem, SMBB and photodiodes and phototransistors. With this wide array of available LED wavelengths and package styles, USHIO products are able to meet the needs of many market segments.

SEMICONDUCTOR

Precise temperature and heating zones are required in the semiconductor industry. The USHIO (QIH) IR lamps provide a precisely controlled IR source that can meet the stringent needs of the semiconductor industry.

FOOD INDUSTRY

Food warming is a large industry that utilizes a variety of (QIH) IR heater lamps to warm food efficiently and effectively. The addition of a reflector on the lamp allows the IR energy to be directed at the food minimizing the energy required to keep food warm.

PAINT & INK DRYING

The importance of using infrared lamps for paint and ink drying applications is the quick and even drying of the paint and ink. This minimizes air movement, streaking, and dust particles adhering to the paint and ink surfaces. Pretreatment and primer coatings can easily be dried to achieve a much faster production process time. Infrared heating for paint applications are most commonly used on aluminum, metal, steel, and wood surfaces. Infrared heating of ink is mostly used for paper, cardboard, and textiles; as well as maintaining a consistent temperature for the ink cartridges.

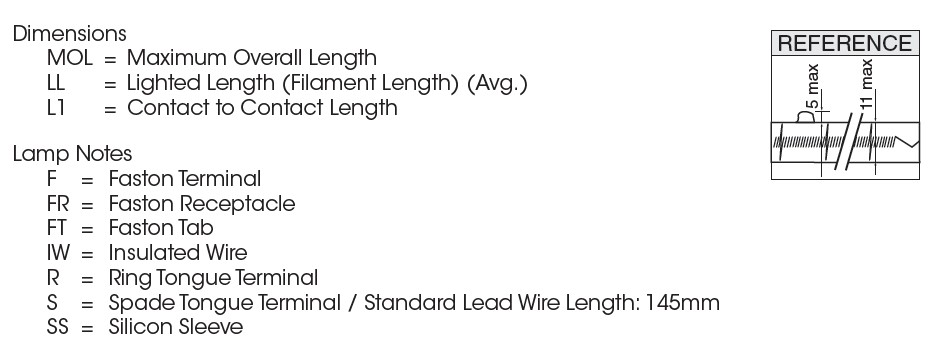

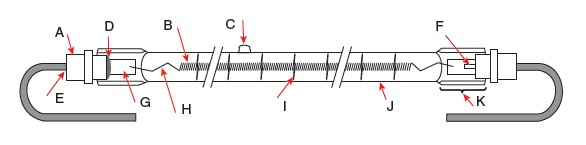

GENERAL PROPERTIES OF A QIH LAMP

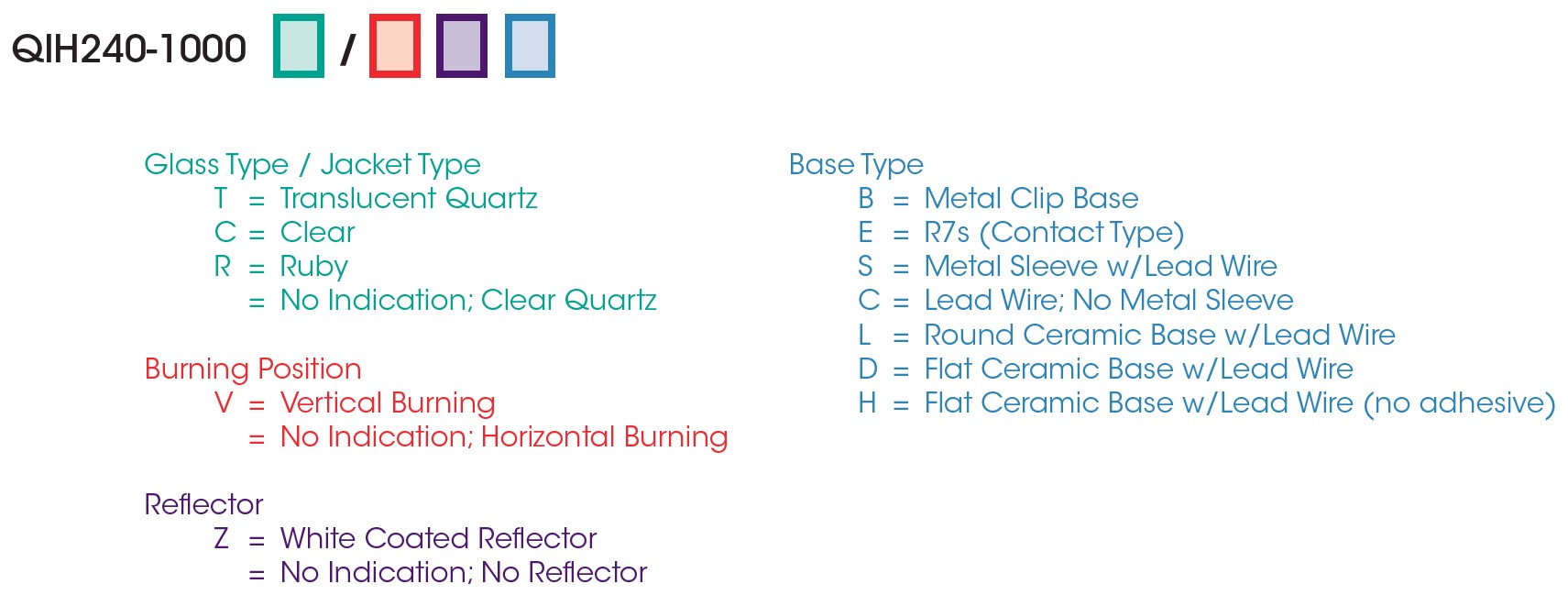

QIH Part Number Reference Guide

QIH Reference Notes