A HOLISTIC APPROACH & STRATEGIC VISION FOR PROCESS SOLUTIONS

PLATE BLANKS

Heating or Cooling

Plate banks are ideal for heating or cooling applications when a single plate is not able to meet the required thermal load. The advantages of a fully assembled plate bank are that all of the plates are connected using a single inlet and outlet connect, making the installation much easier than installing multiple single plates. Plate banks can be configured in many arrangements and can incorporate numerous features that optimize integration and performance of the installed unit; this includes applications for new OEM products or direct replacement parts.

GENERAL FEATURES

Plate banks are integrated assemblies which combine a given number of plates into one singular unit. Generally, all of the plates in a bank assembly are connected to common supply and return header.

Plate banks are available in many different arrangements and can be customized by the selection of:

- Total plate count

- Plate size

- Plate thicknesses

- Materials of construction

- Header locations and connection types

- Plate brace or mounting brackets

All of our plate banks are made with premium surfaces.

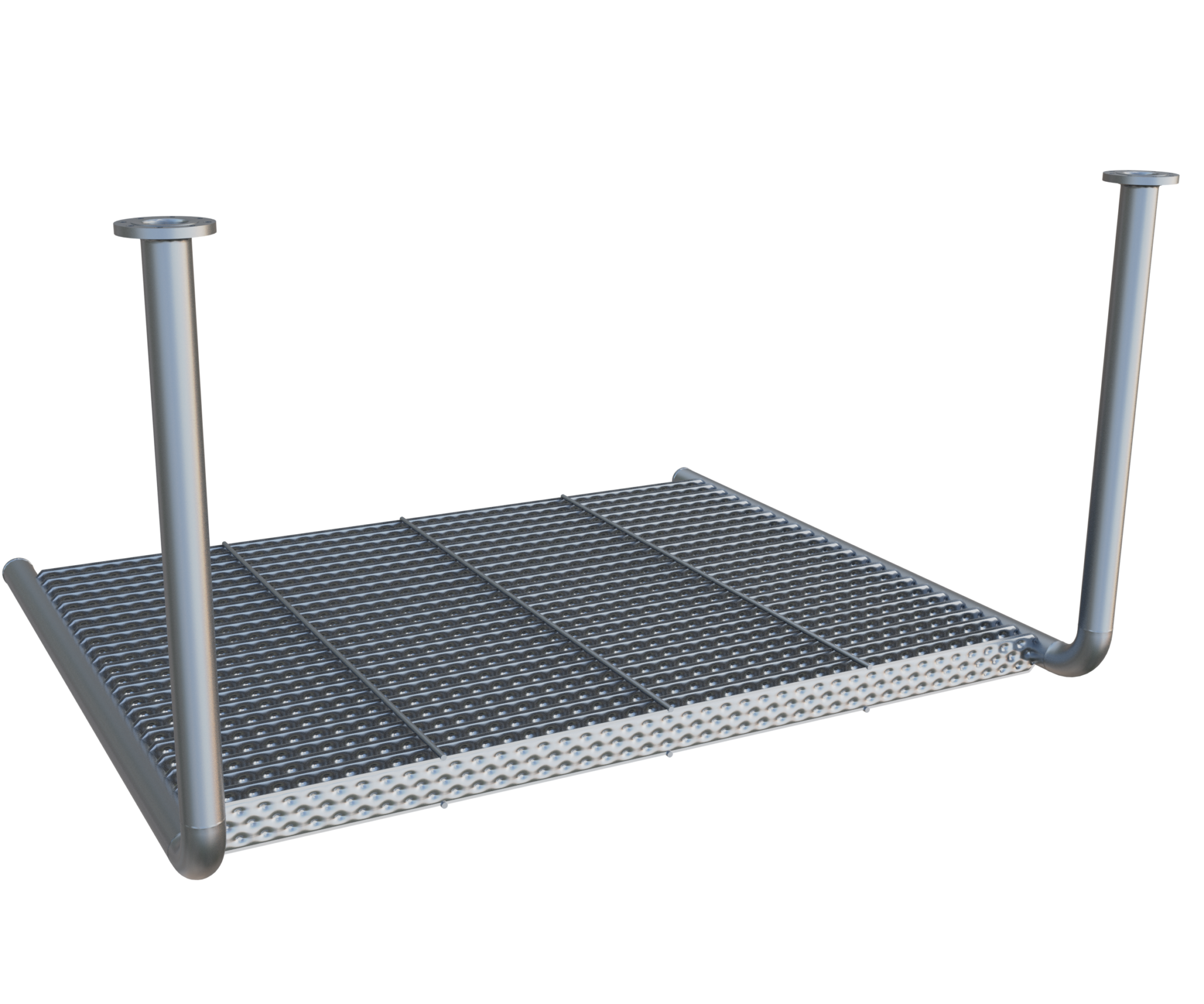

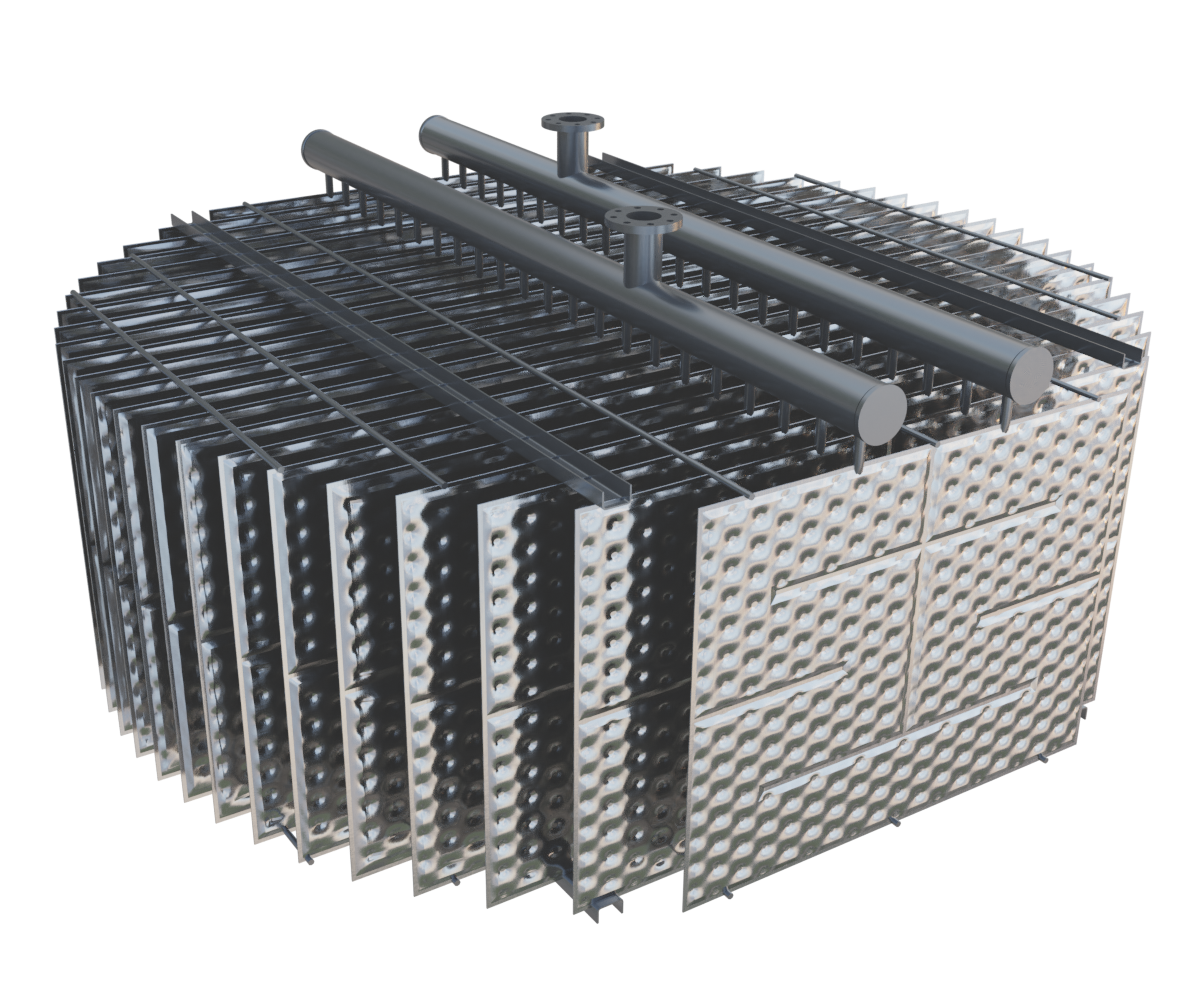

IMMERSION BANKS

The immersion bank arrangement is the most commonly used configuration of the plate bank options. The simple construction is designed for simple submersion into a flooded liquid tank or body of water.

Common Applications:

- General heating or cooling applications

- Geothermal applications

- Thermal storage and ice banks

- Fluidized bed dryers

- Thermal melting

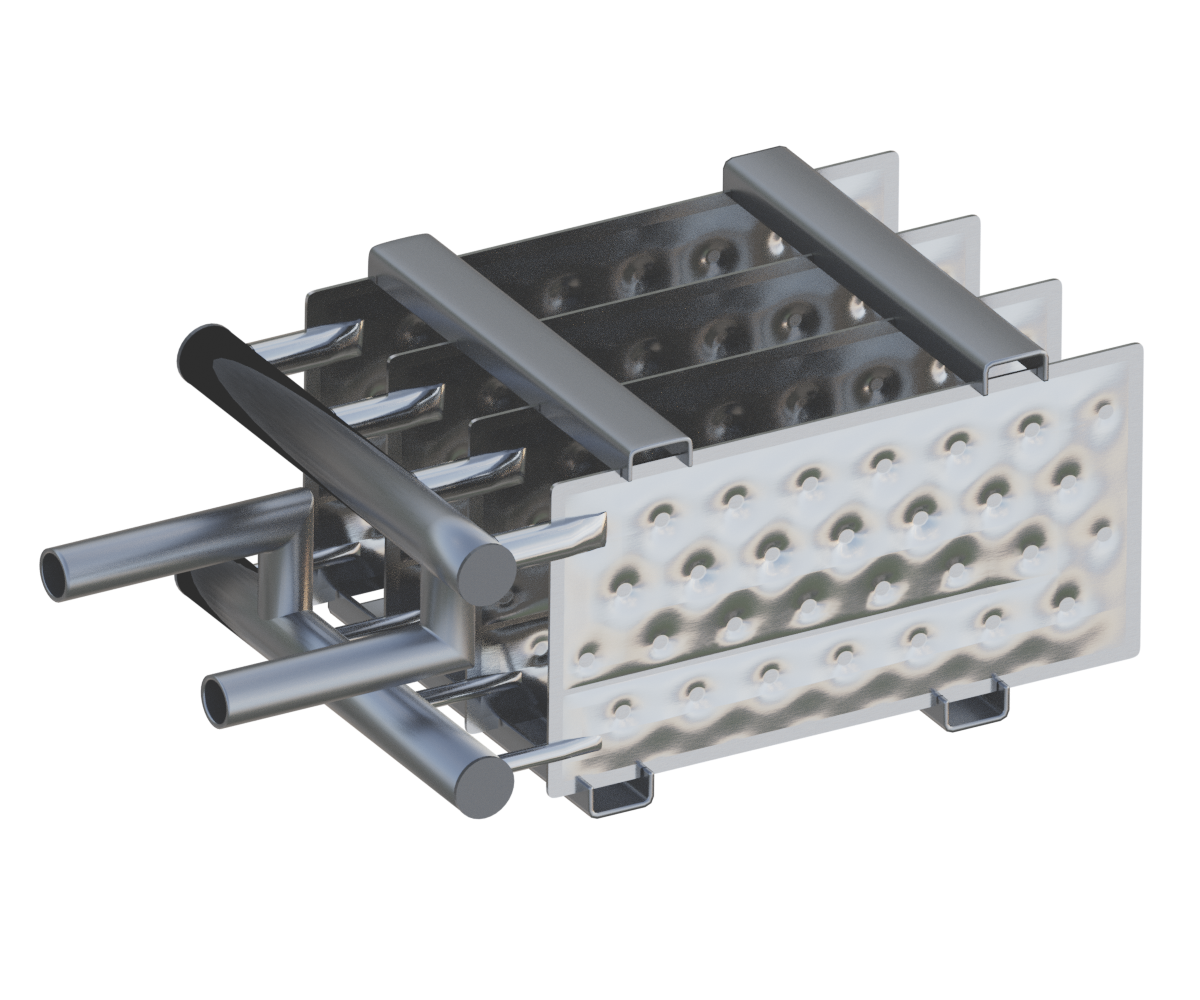

INSERTION BANKS

Insertion style plate banks are plate banks which are mounted to the outer surface of the process equipment. This is achieved with an integrated mounting face plate, which seals against an opening in the process equipment. Depending on the size of the plate bank assembly an internal support or track roller system maybe required.

Common Applications:

- Gas re-heaters

- Contaminated air heaters

- Fluidize bed dryers

- Solids cooling and heating systems

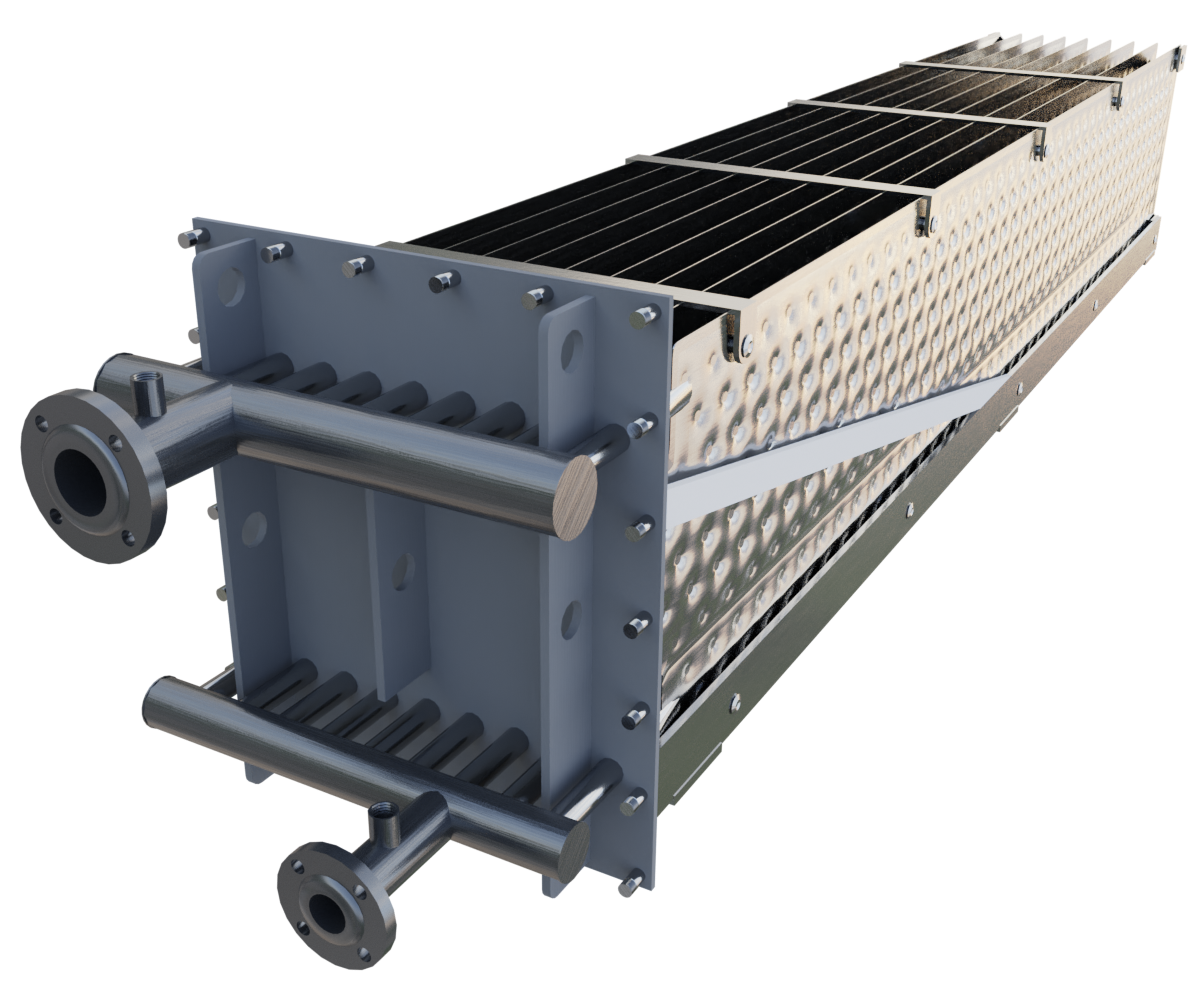

BAYONET STYLE BANKS

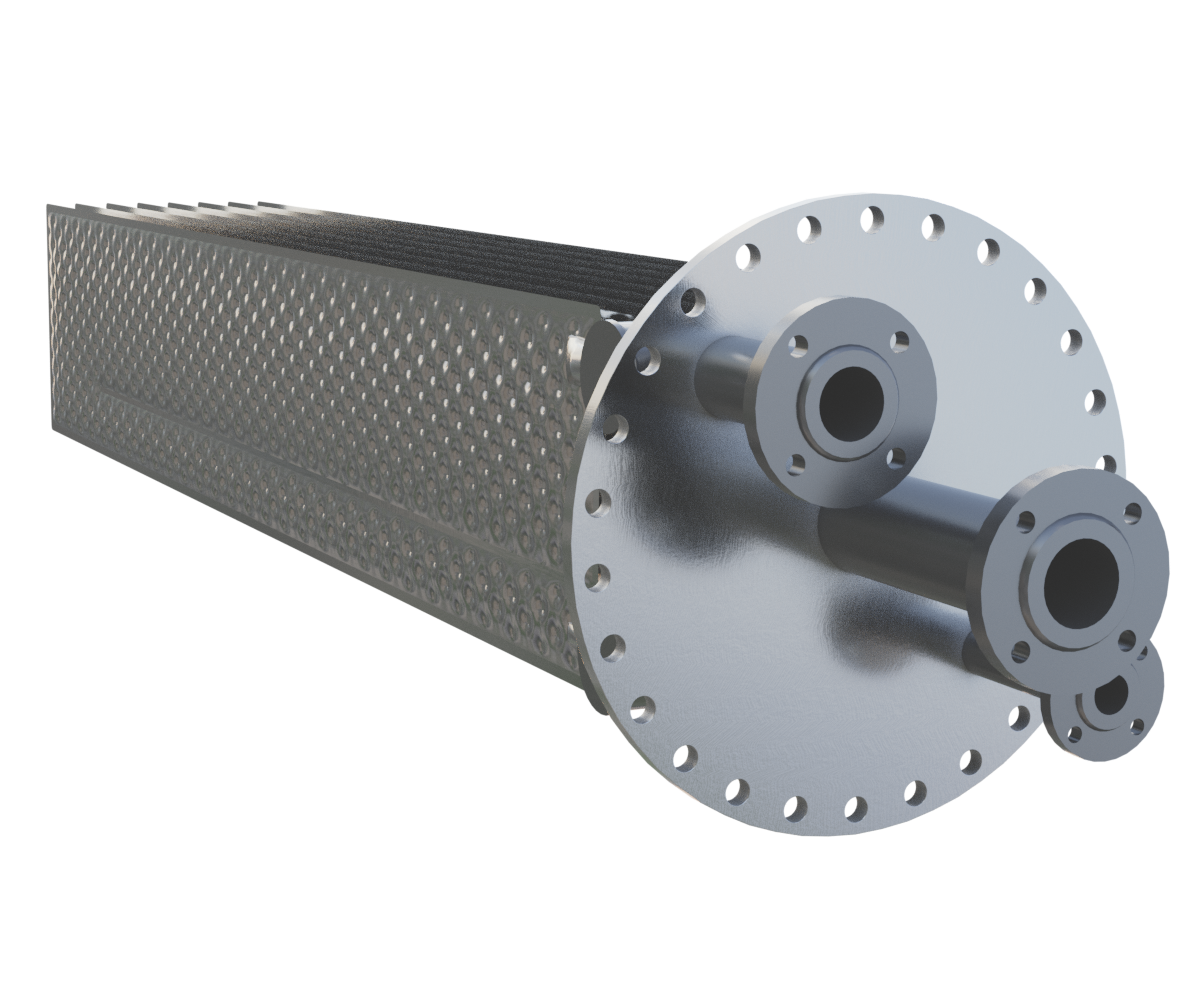

Bayonet style heat exchangers are flange mounted plate bank assemblies. Bayonet style banks are commonly added to API vessels and storage tanks, where a suitable API style manway or large flange connection may be available. These assemblies are designed to fit through the opening of the mounting flange. Smaller units can be self-supporting and large assemblies may require an internal support.

Common Applications:

- General heat and cooling applications

- Suction heaters for viscous product storage tanks

- Tank sump heating and cooling

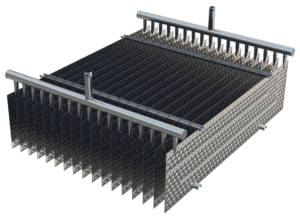

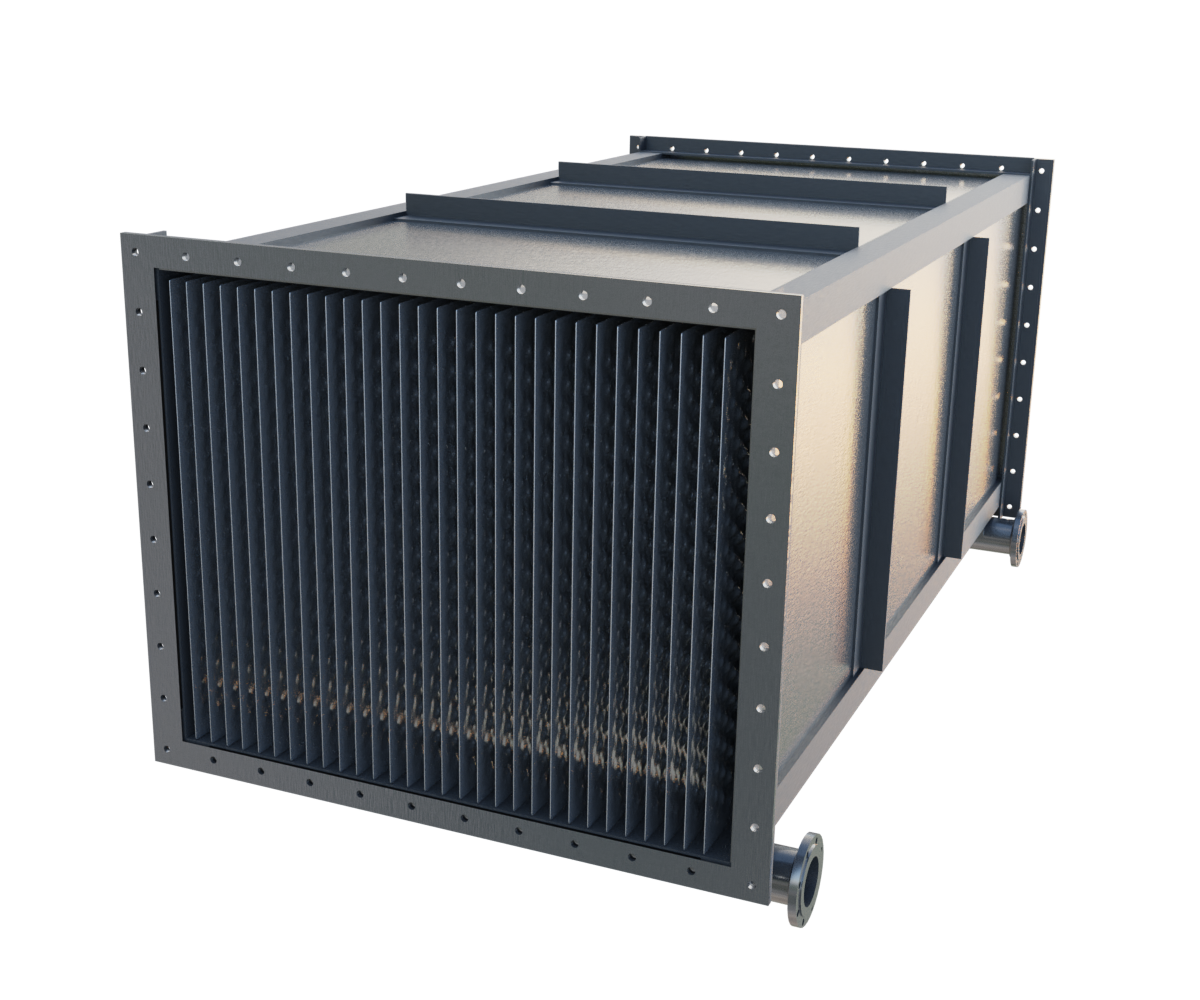

DUCTED BANKS

Ducted plate banks are most commonly used for heat recovery applications where heat can be recovered from ventilation lines. The integrated duct housing of this assembly simplifies the installation into an existing ventilation system. Duct transition sections are available for connection to round ductwork.

Common Applications:

- Heat recovery from ventilation

- Bulk solids heating, cooling, and drying

- Particulate air cooling and drying

SPECIAL APPLICATIONS

The versatility of the surfaces allows us to meet very complex design needs. Contact us with any special application needs.