SURFACE TYPES

PILLOW PLATES

Pillow plates surfaces are a fully welded and inflated type heat exchangers that are manufactured by stacking two flat sheets of material and fuse welding them together with a strategically positioned welding pattern.

A typical welding pattern comprises of an outer seam weld defining the total pressure boundary of the plate and then an interior circle weld pattern specifically configured for the service type and performance requirements for a given application.

Once the welding is complete, the pillow plate will then be expanded by pressurizing the space between the two sheets. As pressure is increased, the gap between the unsupported portions of the plates will increase, creating the identifying “pillow” shaping of the plate.

EMBOSSING OPTIONS

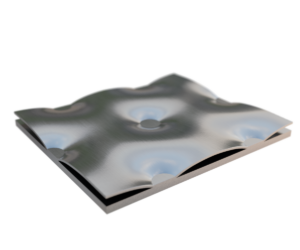

SINGLE EMBOSSED

Thicker bottom / thinner top sheet

Ideal for tank shells

(Process Contact – one side)

Typical Material Combinations:

22ga. on 14ga.

20ga. on 12ga.

18ga. on 10ga.

18ga. on 7ga.

16ga. on 7ga.

18 or 16ga. on 3/16″ plate and heavier

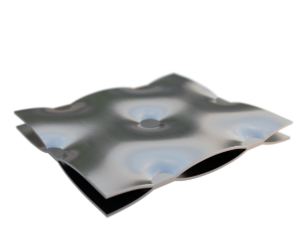

DOUBLE EMBOSSED

Same Thickness top / bottom sheets

Ideal for immersion applications

(Process Contact – both sides)

Typical Material Combinations:

22ga. on 22ga.

20ga. on 20ga.

18ga. on 18ga.

16ga. on 16ga.

14ga. on 14ga.

12ga. on 12ga.

TYPICAL MATERIAL SELECTIONS

RESISTANCE WELDED vs LASER WELDED

What’s the difference?

Both methods produce very similar looking pillow plate surfaces, but there are different advantages between the two options. We manufacture using both methods and we are happy to assist in selecting the best method for your application.

Both methods produce a high-quality product that is ASME Certified and can be provided in a wide range of operating temperatures and pressures.

Got more questions?

A HOLISTIC APPROACH & STRATEGIC VISION FOR PROCESS SOLUTIONS