process air Heaters

Process air heaters are robust hot air components used in industrial and commercial processes. Each heater is designed to work within a range of airflows and air pressures. Generally speaking, Heat Torches are low-flow high-pressure air heaters. Flow Torches are high-flow low-pressure air heaters. Applications include drying, curing, melting, cutting, baking, heat shrinking, de-soldering, metallization, heat staking, sterilization, air scrubbing, laminating, adhesive activation, hot air curtains, and air knives.

Tutco-Farnam has designed over 2,000 different custom air heaters used in factories and OEM equipment around the world. Durability, long life, rapid response time, and efficient heat transfer are goals of the heater design engineer. Our line of pre-designed process air heating solutions evolved from our custom design experience. Over time, we found that some solutions were easily adaptable to a variety of heating applications. Pre-designed solutions are customizable and made to order, so they may not be available for next-day delivery.

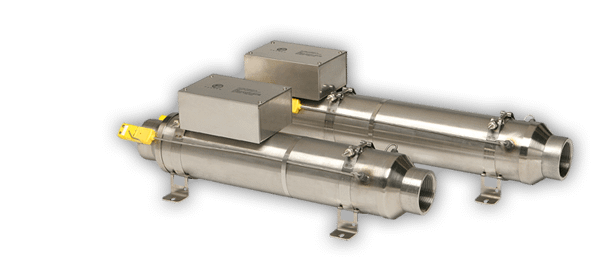

Flow Torch Inline Coil Heaters

The Flow Torch 200 is a 2” diameter stainless steel air heater designed for high flow rates at low pressure drops. It incorporates an open coil spiral wound element of the highest grade material which provides quick heat up and cool down cycles with maximum heat transfer.

The Flow Torch 200 is capable of operation with airflows of up to 115 SCFM and a maximum operating pressure of 120 PSIG*. Maximum output temperature is 900 °F (482 °C). Standard power of 0.5 kW to 6 kW is available in 500 watt increments.

The Flow Torch 200 offers reliable, long-life performance and reduced operational costs. Applications include hot air curtains, air drying, baking, chemical processing, dehumidification, laminating, web drying, textile applications, ink drying, paint baking/drying, plastic curing, metallization, exhaust gas heating, hopper drying and sterilization. Optional equipment includes thermocouple and thermocouple fittings, stainless steel inlet and outlet reducers for hose or pipe. Control Panels are also available to provide precise temperature regulation.Regenerative Blowers available with complete systems.

All Flow Torch Heaters are UL recognized components under UL file number E365755.

* Note: minor leakage through stranded leads.

Additional Flow Torch 200 Information

| MAX WATT | MAX INLET | MAX EXHAUST | MIN SCFM | MAX SCFM | PSIG* |

|---|---|---|---|---|---|

| 6000 W | 250 °F | 900 °F | 10 | 115 | 120 |

The Flow Torch™ 400 is an open coil air heater designed for high flow rates at low pressure drop due to its efficient design with minimal flow restrictions. The robust construction of this 4” diameter stainless steel heater offers reliable long-life performance and reduced operational cost.

The Flow Torch™ 400 incorporates a spiral wound element of the highest grade material, providing quick heat up and cool down cycles with maximum heat transfer.

The Flow Torch™ 400 is capable of operating with airflow of 500 SCFM and a maximum operating pressure of 3 PSIG*. Maximum output temperature is 482°C (900°F).

All Flow Torch Heaters are UL recognized components under UL file number E365755.

Regenerative Blowers available with complete systems.

* Note: minor leakage through stranded leads

Additional Flow Torch 400 Information

New! Flanged Fittings!

We have flanges available as a standard option on our Flow Torch heaters. Click here to build your FT400, FT600 & FT800 with flanged inlet and exhaust fittings.

| MAX WATT | MAX INLET | MAX EXHAUST | MIN SCFM | MAX SCFM | PSIG* |

|---|---|---|---|---|---|

| 35000 W | 250 °F | 900 °F | 19 | 500 | 3 |

The Flow Torch™ 600 is an open coil air heater designed for high flow rates at low pressure drop due to its efficient design with minimal flow restrictions. The robust construction of this 6” diameter stainless steel heater offers reliable long-life performance and reduced operational cost.

The Flow Torch™ 600 incorporates a spiral wound element of the highest grade material, providing quick heat up and cool down cycles with maximum heat transfer.

The Flow Torch™ 600 is capable of operating with airflow of 1100 SCFM and a maximum operating pressure of 3 PSIG*. Maximum output temperature is 482 °C (900 °F).

All Flow Torch Heaters are UL recognized components under UL file number E365755.

Regenerative Blowers available with complete systems.

* Note: minor leakage through stranded leads

Additional Flow Torch 600 Information

| MAX WATT | MAX INLET | MAX EXHAUST | MIN SCFM | MAX SCFM | PSIG* |

|---|---|---|---|---|---|

| 60000 W | 250 °F | 900 °F | 38 | 1100 | 3 |

The Flow Torch™ 800 is an open coil air heater designed for high flow rates at low pressure drop due to its efficient design with minimal flow restrictions. The robust construction of this 8” diameter stainless steel heater offers reliable long-life performance and reduced operational cost.

The Flow Torch™ 800 incorporates a spiral wound element of the highest grade material, providing quick heat up and cool down cycles with maximum heat transfer.

The Flow Torch™ 800 is capable of operating with airflow of 2000 SCFM and a maximum operating pressure of 3 PSIG*. Maximum output temperature is 482°C (900°F).

All Flow Torch Heaters are UL recognized components under UL file number E365755.

* Note: minor leakage through stranded leads

Additional Flow Torch 800 Information

| MAX WATT | MAX INLET | MAX EXHAUST | MIN SCFM | MAX SCFM | PSIG* |

|---|---|---|---|---|---|

| 75000 W | 250 °F | 900 °F | 76 | 2000 | 3 |

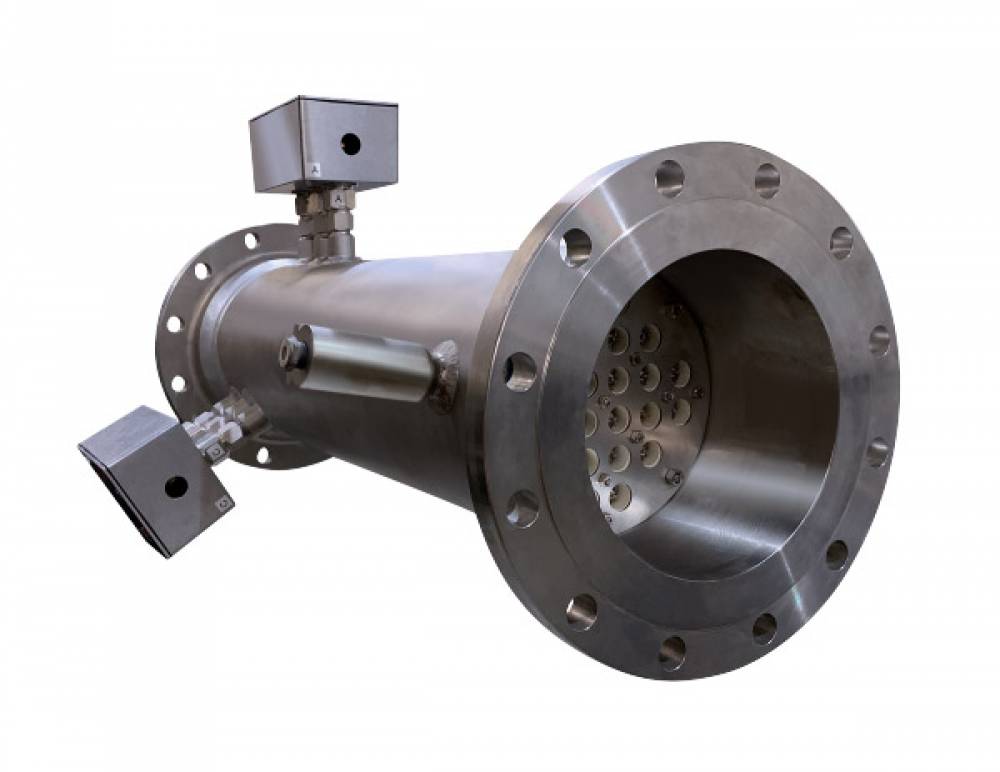

Pressure Flow Torch Inline Coil Heaters

Pressure Torch™ heaters are highly efficient and ideal for heating large airflows. Some of the advantages these process heaters offer are:

- Minimal obstruction to airflow (low pressure drop)

- Ideal for medium pressure (up to 150PSI) blowers

- Support high volume air flow (up to 2000SCFM)

- Heat air up to 482°C (900°F)

- Fast heat up and cool down due to low mass open coil design

- Connected via flange fittings

Farnam has developed three graduated sizes of this platform as an evolution of our popular Flow Torch product line. This family of heaters is offered as a standard product with several wattage and voltage options. Farnam offers application assistance so you can best match the heater to your requirements and needs. Control packages are available and encouraged for these heaters. Pressure Drop Charts are available for quick comparison. Regenerative Blowers available with complete systems.

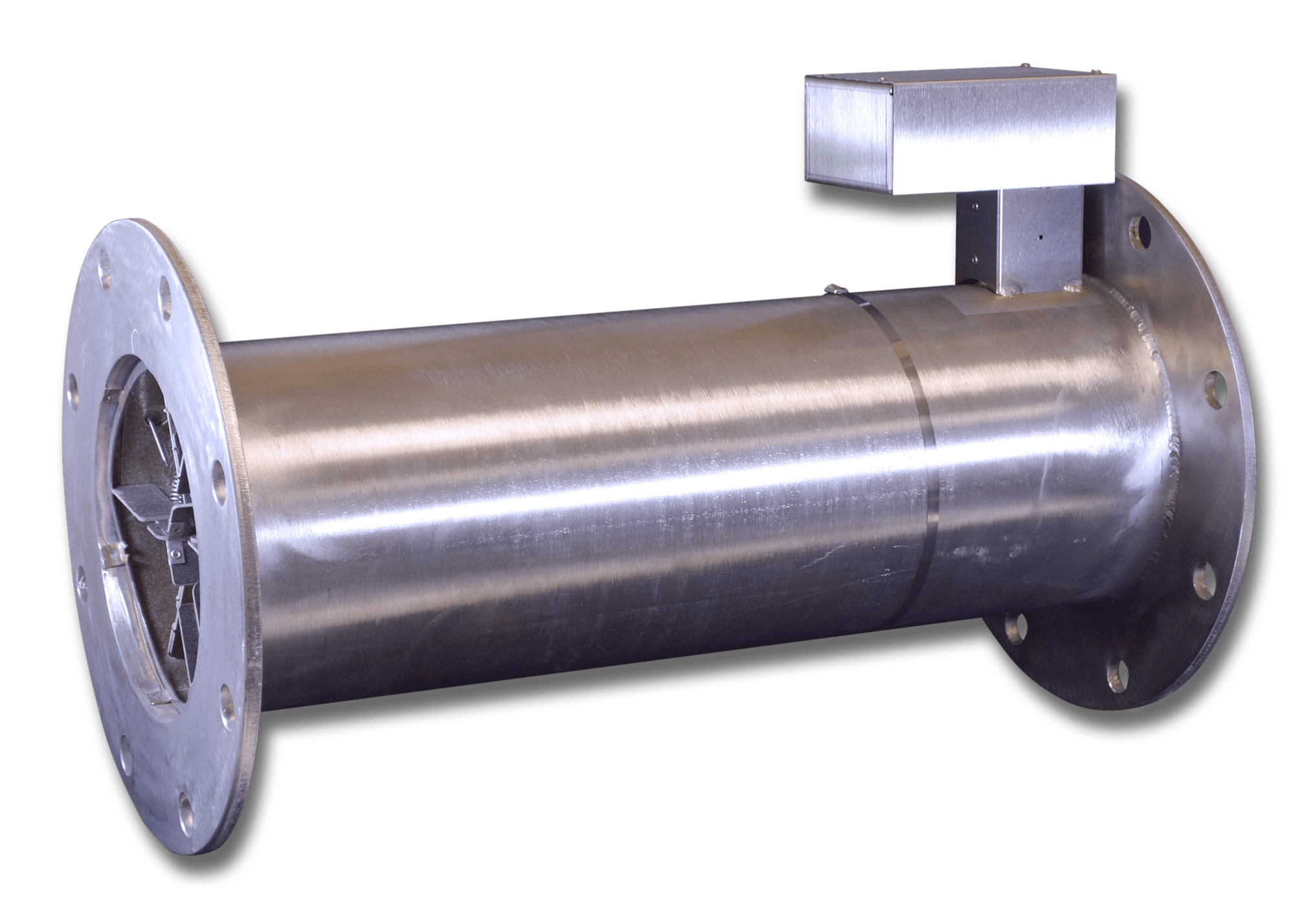

The Pressure Torch™ 400 is an open coil air heater designed for high flow rates at low pressure drop due to its efficient design with minimal flow restrictions. The robust construction of this 4” diameter stainless steel heater offers reliable long-life performance and reduced operational cost.

The Pressure Torch™ 400 incorporates a spiral wound element of the highest grade material, providing quick heat up and cool down cycles with maximum heat transfer.

The Pressure Torch™ 400 is capable of operating with airflow of 500 SCFM and a maximum operating pressure of 150 PSIG. Maximum output temperature is 482°C (900°F).

Regenerative Blowers available with complete systems.

| MAX WATT | MAX INLET | MAX EXHAUST | MIN SCFM | MAX SCFM | PSIG* |

|---|---|---|---|---|---|

| 35000 W | 250 °F | 900 °F | 19 | 500 | 150 |

The Pressure Torch™ 600 is an open coil air heater designed for high flow rates at low pressure drop due to its efficient design with minimal flow restrictions. The robust construction of this 6” diameter stainless steel heater offers reliable long-life performance and reduced operational cost.

The Pressure Torch™ 600 incorporates a spiral wound element of the highest grade material, providing quick heat up and cool down cycles with maximum heat transfer.

The Pressure Torch™ 600 is capable of operating with airflow of 1100 SCFM and a maximum operating pressure of 150 PSIG. Maximum output temperature is 482 °C (900 °F).

Regenerative Blowers available with complete systems.

| MAX WATT | MAX INLET | MAX EXHAUST | MIN SCFM | MAX SCFM | PSIG* |

|---|---|---|---|---|---|

| 60000 W | 250 °F | 900 °F | 38 | 1100 | 150 |

The Pressure Torch™ 800 is an open coil air heater designed for high flow rates at low pressure drop due to its efficient design with minimal flow restrictions. The robust construction of this 8” diameter stainless steel heater offers reliable long-life performance and reduced operational cost.

The Pressure Torch™ 800 incorporates a spiral wound element of the highest-grade material, providing quick heat up and cool down cycles with maximum heat transfer.

The Pressure Torch™ 800 is capable of operating with airflow of 2000 SCFM and a maximum operating pressure of 150 PSI. Maximum output temperature is 482°C (900°F).

Regenerative Blowers available with complete systems.

| MAX WATT | MAX INLET | MAX EXHAUST | MIN SCFM | MAX SCFM | PSIG* |

|---|---|---|---|---|---|

| 75000 W | 250 °F | 900 °F | 76 | 2000 | 150 |

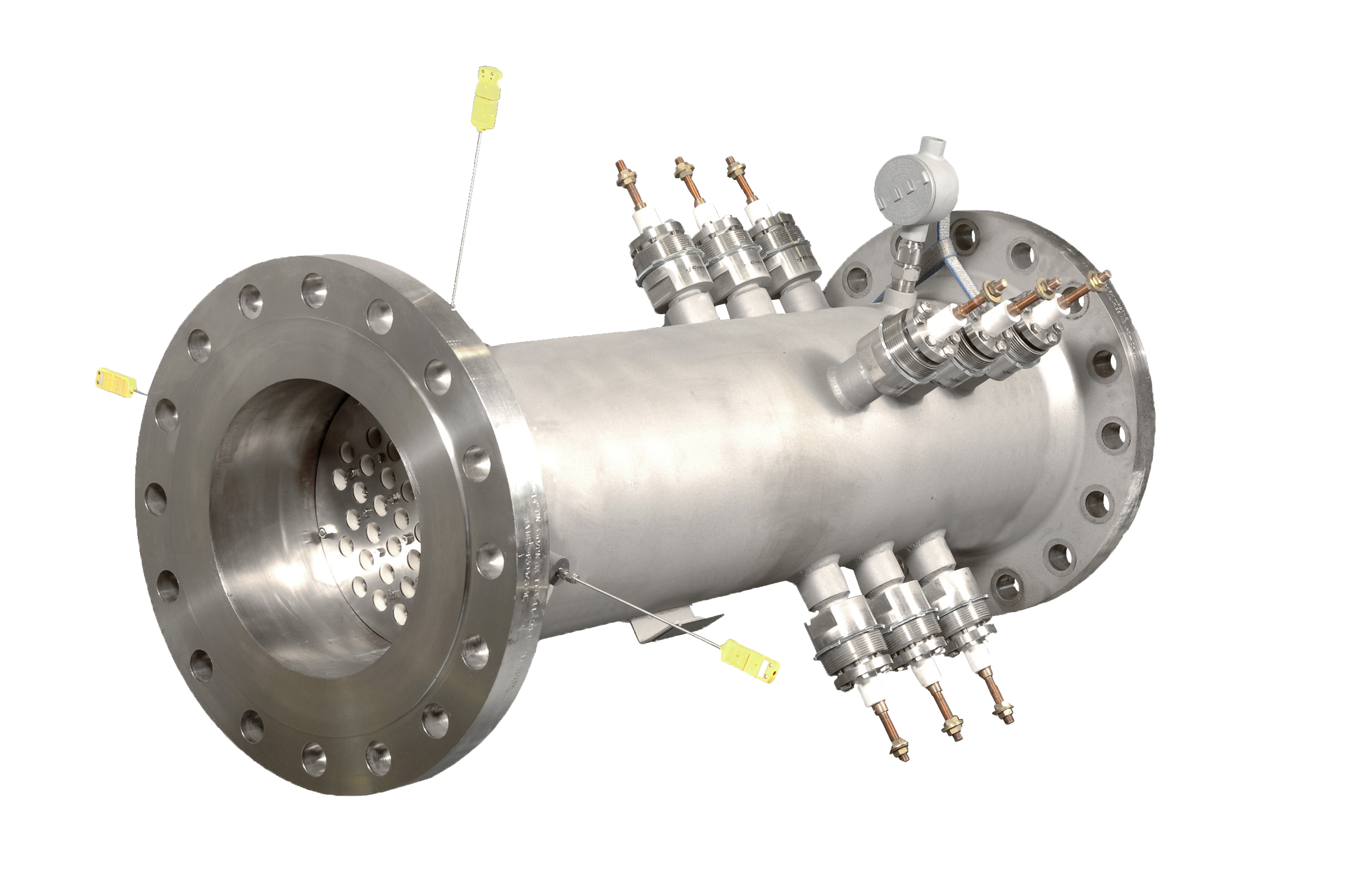

Custom Specialty Heaters

If a standard threaded inline air heater solution is not suitable for your application we can provide a custom inline solution to meet your high temperature or high pressure needs.

Specialty Flanged Inline (SFI) inline heaters offer superior performance over conventional sheathed (“tubular” or “immersion”) style heaters because they are designed specifically for air and inert gas applications. Our proprietary SERPENTINE™ technology facilitates a very high power density and compact overall design. SFI heaters can be as much as 8-12X smaller than equivalent tubular/immersion designs. With this advantage, installations become smaller, lighter, and more cost effective, with a faster heat-up and cool-down time. Whether for a research test stand, factory production line, or key component in a product or system, our Specialty Flanged Inline heater is the right heater solution for the job.

Inline Duct Heaters provide ultra-compact, fast response heating for a multitude of industrial and research applications where gas pressure is ≤ 10 PSI (.7 Bar) and temperatures up to 1475°F (800 °C)

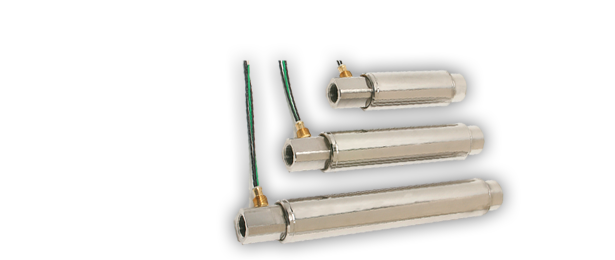

Tutco-Farnam has been manufacturing high-quality inline heaters for over two decades. Tens of thousands of these devices have been built for many Fortune 1000 companies on a custom order basis. Based on this experience and increased demand, we created a family of Heat Torch™ process heaters which can be modularly assembled from a set of components to provide the best of both standardization and flexibility.

Farnam Heat Torch™ inline air heaters are ideal for rapidly heating compressed air or any non-combustible gas. Industrial strength open coil heating elements provide efficient heat transfer through direct contact with high-pressure airflow. Rapid heater response time enables precise output temperature control when these heaters are paired with off the shelf sensors and controllers. Robust design, high-quality materials, and workmanship provide long life and performance margin. We provide pressure testing for any of our Heat Torch™ products as an add-on service.

Our highly efficient Cool Touch™ heat torch option minimizes the skin temperature of the heater and helps protect people and products from hot surfaces. This very efficient design reduces heat losses.

The large thermal storage capacity is particularly useful if you have an application requiring intermittent use and rapid response. This Cool Touch™ option is available for a variety of our Heat Torch sizes. We provide pressure testing for any of our Cool Touch™ products as an add-on service.

PRODUCT PART NUMBER GUIDE

Series products

- F010226 SERIES I STYLE A 1,050W 180V

- F014372 SERIES I STYLE A 1,000W 130V

- F014682 SERIES I STYLE B 680W 145V

- F014683 SERIES I STYLE B 650W 180V

- F015509 SERIES I SHIELD OPEN END FOR 17 OHM

- F016501 SERIES II STYLE A 1,125W 130V

- F016502 SERIES II STYLE B 600W 95V

- F016503 SERIES II STYLE A 850W 80V

- F016504 SERIES II STYLE B 650W 70V

- F017558 SERIES III STYLE A 2,050W 160V

- F017575 SERIES III STYLE B 1,450W 135V

- F017853 SERIES II SHIELD OPEN END

- F037261 SERIES I SHIELD FLARED FOR 31 OHM

- F038449 SERIES I STYLE A BALCO 4.2 OHM BALCO

- F057083 SERIES I SHIELD OPEN END FOR 31 OHM

- F062543 SERIES III STYLE A W/CERAMIC TUBE

- F046198 QUARTZ TUBE SERIES IB (B790108-02M)

- F046199 QUARTZ TUBE SERIES IB (B790108-03L)

HOT AIR TOOLS

- F068462 HAT HEATER 1.5kW 120V 1PH

- F068463 HAT HEATER 2.0kW 240V 1PH

- F068464 HAT HEATER 3.5kW 240V 1PH

- F068472 HAT FLARE 2.5” x .06”

- F072239 HAT HEATER 4.5 OHM BALCO

SERPENTINE PRODUCTS

- F029485 SERP II TC PORT ADAPTOR (WITH TC)

- F029763 SERP II REPL HSG (NO ELEMENT)

- F029765 SERP II REPL ELE 2.0kW 240V 1PH

- F029766 SERP II REPL ELE 2.8kW 240V 1PH

- F029767 SERP II REPL ELE 3.6kW 240V 1PH

- F039739 SERP II BASE ADAPTOR ASSY

- F040291 SERP VI REPL ELE 5kW 240V 1PH

- F040292 SERP VI REPL ELE 6kW 240V

- F040299 SERP VI TC ASSY (W/HOLDER & TC)

- F041612 SERP II FLARE WITH TC PORT (NO TC)

- F042339 SERP VI BASE ADAPTOR ASSY

- F048917 SERP II REPL ELE 3.6kW 240V 1PH W CERAMIC TUBE

- F054007 SERP II REPL ELE 4.5 OHM BALCO

- F056548 SERP VI REPL ELE 8kW 240V 1PH

- F057088 SERP VI REPL HSG (NO ELEMENT)

- F060418 SERP II REPL ELE 3.6kW 240V 1PH 2STG

- F061429 SERP VI REPL ELE 6kW 240V 1PH 2 STG

- F068828 SERP II LEAD ASSY PR 10FT

- F068861 SERP VI REP ELE 3.0kW 240V 1PH BLK ADAPT

- F068863 SERP VI REPL ELE 6kW 240V 1PH BLK ADAPT

- F071341 SERP VI REPL HOUSING (BAFFLED)

- F071539 SERP VI 6kW 240V 2ST PLASTIC

- F071928 SERP VI REP ELE 6.0kW 240V 1PH BLK ADAPT

- F073248 SERP VI TC HOLDER (NO TC)

- F073921 SERP VI REPL HSG (NO ADAPTOR)

- F074157 SERP VI REP ELE 8.0kW 240V 1PH BLK ADAPT

- F076541 SERP VI 6kW 240V W/ RAD 10.31” LG

- F075775 SERP II REPL RR ADAPTOR W/3M LEADS

- F076635 SERP VI ELE 8KW 240V 1PH 10.31

- F205093 SERP VI ADAPTOR ASSY 10’ LEAD

MAX & MAX HT PRODUCTS

- F074723 MAX 6kW 240V 1PH

- F074724 MAX 6kW 240V 3PH

- F074725 MAX 6kW 380V 3PH

- F074726 MAX 6kW 480V 3PH

- F074727 MAX 10kW 240V 1PH

- F074728 MAX 10kW 240V 3PH

- F074729 MAX 10kW 380V 3PH

- F074731 MAX 10kW 480V 3PH

- F074732 MAX 18kW 240V 3PH

- F074733 MAX 18kW 380V 3PH

- F074734 MAX 18kW 480V 3PH

- F074735 MAX 30kW 380V 3PH

- F074736 MAX 36kW 480V 3PH

- F076250 MAX HT 18kW 240V 3PH

- F076518 MAX HT 18KW 480V 3P

- F076189 MAX HT 30kW 380V 3PH

- F076197 MAX HT 36KW 480V 3PH

- F205773 MAX HT REPL ELE (F076250) 18kW 240V

- F205772 MAX HT REPL ELE (F076189) 30kW 380V

- F205713 MAX HT REPL ELE (F076197) 36kW 480V

- F077081 MAX HT, UL, 18kW, 240V / 3PH

- F077082 MAX HT, UL, 18kW, 380V / 3PH

- F077083 MAX HT, UL, 18kW, 480V / 3PH

- F077084 MAX HT, UL, 30kW, 380V / 3PH

- F077085 MAX HT, UL, 36kW, 480V / 3PH

- F206707 MAX HT REPL ELE (F078081) 18KW; 240 / 3PH

- F206662 MAX HT REPL ELE (F078082) 18KW; 380 / 3PH

- F206663 MAX HT REPL ELE (F078083) 18KW; 480 / 3PH

- F206664 MAX HT REPL ELE (F078084) 30KW; 380 / 3PH

- F206598 MAX HT REPL ELE (F078085) 36KW; 480 / 3PH

- F078135 240VAC or 480VAC / 30A / 3PH / 50-60Hz (replacing F076753 and F076754) no CE

- F078252 CONTROL PANEL/NEMA 12/30A/480V/3PH (same as F078135) with CE

- F078216 CONTROL PANEL/NEMA 12/30A/400V/3PH (replacing F076905)__with CE

- F078217 CONTROL PANEL/NEMA 12/60A/400V/3PH (replacing F076906)_ with CE

- F078253 CONTROL PANEL/NEMA 12/60A/480V/3PH (same as F078136) with CE

- F078136 CONTROL PANEL/NEMA 12/60A/480V/3PH (replacing F076755 and F076756) no CE

CONTROL PRODUCTS & ACCESSORIES

- F039272 CONTROL THERMOCOUPLE K TYPE 3/16” DIA

- F057081 CONTROL POWER 25A 277V 1PH MANUAL

- F065832 TC PORT ADAPTOR (NO TC)

- F066823 CONTROL POWER 30A 240V 1PH 4-20 mA

- F072762 CONTROL POWER 250A 480V 3PH

- F072763 CONTROL POWER 200A 480V 3PH

- F072764 CONTROL POWER 100A 480V 3PH

- F072765 CONTROL POWER 60A 480V 3PH

- F073262 CONTROL OTEMP 4 INPUT FOR FLANGED INLINE

- F074829 CONTROL EXIT TEMP 1/16 DIN (ATHENA 16C)

- F074831 CONTROL INLET TEMP (DC OUTPUT)

- F074832 CONTROL SSR ASSEMBLY 50A 1PH

- F074835 CONTROL INLET TEMP (RELAY OUTPUT)

- F076359 CONTROL-86L RELAY OUT 1000c

- F076361 CONTROL TEMP 1/16 DIN 4-20 MA OUTPUT

- F076417 CONTROL SCR 480V 3PH 30A

- F205863 CONTROL – TEMP 1/8 DIN WITH RSP

- F206119 1/8” TC TYPE K 12” PROBE

skorpion products

- F075615 SKORPION 1.5KW 120V

- F075616 SKORPION 3.0KW 240V

- F075744 SKORPION NOZZLE

- F075745 SKORPION FLARE 150MM

- F075746 SKORPION FLARE 300MM

- F075835 SKORPION 3.0KW 240V W/O BLOWER

- F075869 SKORPION 1.5KW 120V W/O BLOWER

- F076008 SKORPION 4.5KW 230V

- F076029 SKORPION 4.5KW 230V W/O BLOWER

- F076436 SKORPION 3.0KW 230V HIGH FLOW

- F205486 SKORPION REPL SSR

- F205499 SKORPION REPL TEMP CONTROL

- F205502 SKORPION REPL ELEMENT 3.0KW

- F205526 SKORPION REPL ELEMENT 1.5KW

- F205549 SKORPION – ADAPTOR PLATE

- F205614 SKORPION REPL ELEMENT 4.5KW

SRE PRODUCTS

- F068535 SRE 2.75” 7.0kW 240V 3PH

- F068539 SRE 2.75” 7.0kW 480V 3PH

- F068541 SRE 2.75” 9.0KW 480V 3PH

- F068544 SRE 3.50” 12.0kW 240V 3PH

- F068547 SRE 3.50” 12.0kW 480V 3PH

- F068577 SRE 2.75” 6.0kW 380V 3PH

- F068578 SRE 2.75” 7.5KW 380V 3PH

- F068581 SRE 3.50” 10.0kW 380V 3PH

- F072887 SRE 2.75” 6.0kW 440V 3PH

THREADED INLINE

- F038821 THD INLINE STY A 3/8” NPT 1.6KW 170V

- F038822 THD INLINE STY B 3/8” NPT 1.6KW 170V

- F038823 THD INLINE STY A 1/2” NPT 4.0KW 220V

- F038824 THD INLINE STY B 1/2” NPT 4.0KW 220V

- F038825 THD INLINE STY A 1-1/4” NPT 6.0KW 220V

- F038826 THD INLINE STY B 1-1/4” NPT 6.0KW 220V

- F057972 THD INLINE STY A 1/2” NPT 4.5 OHM BALCO

- F060989 THD INLINE STY B 3/8” NPT 4.5 OHM BALCO

- F061293 THD INLINE 1/2” STYLE B 2.2 OHM BALCO

- F063007 THD INLINE STY B 2-1/2” NPT 18.0KW 240V

- F063422 THD INLINE 1-1/4” STYLE A BALCO 4 OHM

- F074439 THD INLINE STY B 2-1/2” NPT 24.0kW 240V

- F076339 THD INL 1-1/4” 6kW 208V-HI TEMP

- F076358 THD INL 2.5” 24kW 480V 3PH 316SS

- F076418 THD INLINE STYLE B 2-2 1/2” NPT 18kW 480V

- F076523 THD INL 1-1/4” 15KW 480V 1PH 316H MNPT E

- F076525 THD INL 1-1/4” 6kW 208V HI TEMP – NPT EX

- F076619 THD INL HTR 1-1/4 8KW 240V 1PH

- F076495 THD INL HTR 1-1/4” 15KW 480V 1PH 31A 316H

- F077362 THD INL HTR 1-1/4” 6kW 220V 1PH Style B with TC

- F077056 TC ADAPTOR 3/8” THREADED INLINE

- F077057 TC ADAPTOR 1/2” THREADED INLINE

- F077058 TC ADAPTOR 1-1/4” THREADED INLINE

- F077059 TC ADAPTOR 2-1/2” THREADED INLINE

JET PRODUCTS

- F074718 JET 3.0kW 240V 1PH

- F074719 JET 8.0kW 240V 1PH

- F074722 CONTROL SUREHEAT JET 240V 40A

- F075526 CONTROL SUREHEAT JET W/RS-232 COM