←Flat Panel

Ceramic infrared panel

Infrared Radiant Heaters Home→

Ceramic Infrared Heater is a type of heating device that utilizes ceramic elements to produce and emit infrared radiation, which transfers heat directly to objects and people in its path. These heaters typically consist of a ceramic plate or coils that heat up when electricity passes through them. They emit infrared rays that warm up nearby objects by penetrating the air without actually heating it directly, making them an efficient and quick heating solution. Ceramic infrared heaters are known for their energy efficiency, rapid heating capabilities, and ability to provide focused warmth in specific areas.

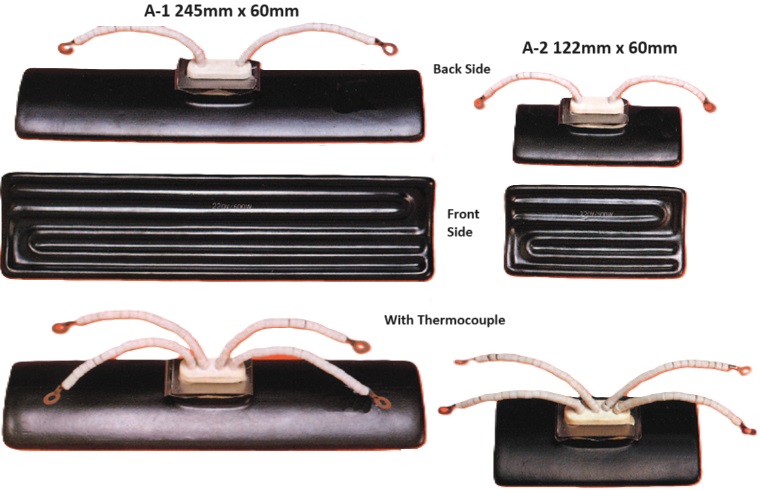

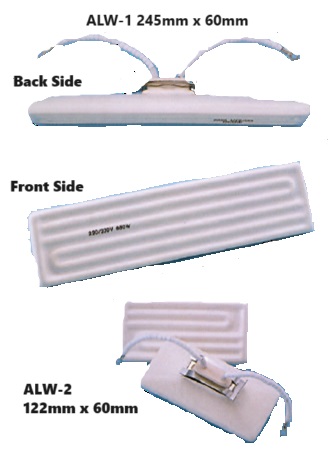

SFH Super Flat Radiators are ceramic infrared radiators in flat design. They reach operating temperatures up to 800°C and surface ratings up to 64 kW/m². The radiators of the SFH series are very suited for applications, which require space-saving installation. The borders of SFH radiators are used as bearing surface on a metal mounting sheet or reflector. For each radiator a corresponding rounded mounting hole is required to place the heaters into them. When mounting SFH super flat radiators a heat insulation can be added additionally. A temperature resistant insulating material can be applied on site directly on the back of the radiator. SFH super flat radiators are available in four designs and cover the power range from 60 W to 1000 W.

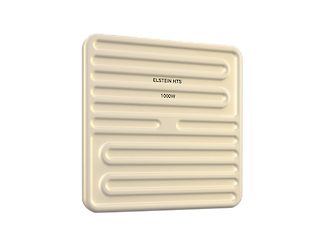

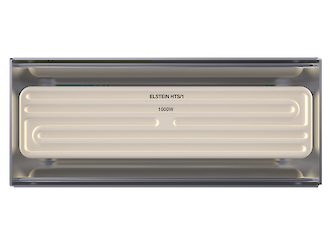

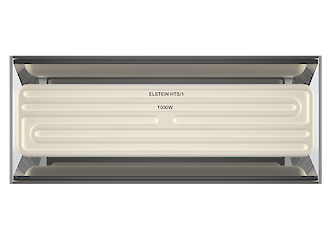

HTS

(Energy saving)

Elstein HTS high temperature heaters are ceramic infrared panel heaters, which can be used for operating temperatures up to 860 °C and surface ratings up to 64 kW/m².

HTS heaters are produced using a hollow-casting ceramic process and are filled with thermal insulation material. This improves the radiant power output to the material to be heated.

Furthermore, there is a significant reduction in heat dissipated in the wiring space, so that additional insulation of the heating area is usually not required.

Compared with IR heaters, which are produced by using full-poured casting processes, HTS heaters have a considerably reduced heating-up time and, depending on the type of application, enable energy savings of up to 25 %.

Elstein HTS high temperature heaters are available in four designs and cover the power range from 60 W to 1,000 W.

SHTS

(Max Power, Panel Radiator)

Elstein SHTS super high temperature heaters were developed to increase the previous maximum possible surface rating of ceramic panel heaters from 64 kW/m² to 77 kW/m².

The SHTS heaters, produced using a hollow casting ceramic process, are filled with thermal insulation material and have a special black glaze and a gold-plated back. At an operating temperature of 860 °C, over 75 % of the electrical energy supplied is transferred to the material to be heated as medium to long-wave IR radiation.

SHTS heaters are therefore particularly suitable for use in plant construction in which special solutions have to be drawn up for the customer’s specific needs and for applications requiring high outputs.

The four standard designs cover the power range from 300 W to 1,200 W and have customary market dimensions regarding the Elstein product range. Existing IR equipments can therefore be retrofitted with Elstein SHTS heaters.

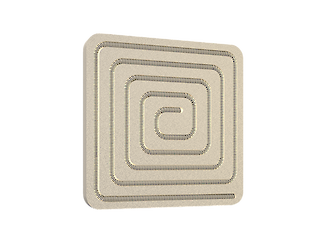

HSR

(Short heat-up/cool-down time)

Elstein High Speed Radiators HSR are especially suitable for use in clocked production processes, with frequent tool changes or when the temperature has to drop quickly in the event of transfer disruptions in order to avoid damage to a production plant.

They are fast-reacting ceramic infrared panel heaters, designed for operating temperatures of up to 900 °C and area outputs of up to 64 kW/m².

The external feature of the HSR heater is the visible heating coil, which is built into a ceramic body. Compared to infrared heaters with a heating coil embedded in ceramic, this design offers up to 65 % less heating and cooling times as well as reduced heat dissipation into the wiring space.

Elstein High Speed Radiators HSR are standardly available in three designs and cover the power range from 125 W to 1,000 W.

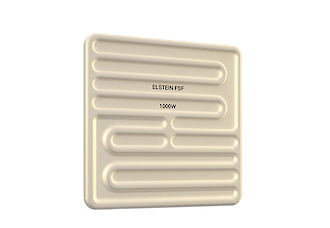

FSF

(Max service life)

Elstein FSF series heaters can be used universally. Due to the low height of the elements, space-saving installation is possible. Compared to other heaters, the height of the FSF elements, measured from the radiating surface to the mounting plate, has been reduced by approx. 45 %.

Elstein FSF panel heaters are ceramic infrared heaters with a low overall height. They are manufactured using a full ceramic casting process and are designed for operating temperatures of up to 750 °C and area outputs of up to 64 kW/m².

Elstein FSF are available as standard in four designs with standard Elstein panel heater dimensions and cover the power range from 60 W to 1,000 W.

FSR

(Proved Quality)

Elstein FSR panel heaters can be used universally and are suitable for building up heating systems with any geometry.

With the FSR panel radiators, Elstein-Werk has been setting the globally recognized standards for ceramic infrared heaters in terms of shape, design, performance and quality since 1952.

Elstein FSR are ceramic infrared emitters that are designed for operating temperatures of up to 750 °C. Optionally, area outputs of up to 64 kW/m² can be installed.

They are manufactured using a full ceramic casting process and are characterized by their concave design. Due to this design, there is a gap between the radiator and the mounting plate, which reduces the heat absorption of the wiring space.

They are available in three standard designs and cover the power range from 60 W to 1,000 W.

IOT Screw Heater

(Easy Connection E27 Base)

Elstein screw-in elements of the IOT series are ceramic infrared elements with an E27 screw base.

The emitters of the IOT series are so-called “dark emitters” that do not emit any visible light and, due to this property, the robustness, especially in the heaters’ socket area as well as the simple temperature control options (e.g. with standard dimmers), have been used successfully for millions of times, for decades. They are used e.g. in animal breeding or terrariums and are perceived by animals (self-warm and cold-blooded), especially during the night, as a non-disturbing source of warmth.

The standardized E27 thread enables simple and safe installation, as the elements can be screwed into porcelain sockets or metal sockets with a porcelain insert like lightbulbs.

Elstein IOT infrared elements are suitable because of their simple connection options for both individual operation and for setting up groups of heaters. The possible uses are diverse and, in addition to animal breeding and terraristics, particularly extend to the areas of medical and gastronomy technology.

The standard IOT/75 and IOT/90 emitters are available each in two power levels of 60 W and 100 W or 150 W and 250 W.

BSI Stainless Steel

Elstein BSI standard construction panels are high-quality infrared heating systems, which can be equipped with ceramic IR panel heaters HTS or HSR.

The ceramic infrared panel heaters are fixed to the MBO mounting sheets and are surrounded by a housing of frame and capping sections.

All housing parts consist of stainless steel (German-made) so that heaters with high power can be used, too.

The BSI construction panels are factory assembled so that the user inserts the heating panel into a steel section frame to be made on-site, and connect the panel with the electricity mains.

Elstein construction panels are suited for building infrared heating areas in any dimensions.

EBI Stainless Steel

If there is the requirement to equip machines or systems with compact, robust and long-lasting linear infrared heating systems – while at the same time economical and technical effort for the heating should be minimized – Elstein EBI systems enable a standardized option to meet these requirements.

Elstein EBI construction elements are infrared radiation systems with housing parts made of stainless steel (German-made). EBI systems are corrosion-resistant and very stable both mechanically and thermally. They are therefore particularly suitable for applications in which such requirements shall be met; for example in the food industry.

The EBI components are delivered assembled. They can be equipped with many Elstein panel heaters, whereby a combination of different heater designs and wattages is possible.

The user simply and finally does the wiring, the attachment of the EBI elements to a profile steel frame created on-site and the connection to the electrical network.

Elstein EBI components are available in five standard lengths, which can be combined to realize radiation surfaces in any geometry and installation position.

EBF Aluminum

Elstein EBF construction panels are delivered assembled. They can be equipped with many Elstein panel heaters, whereby a combination of different heater designs and wattages is possible.

The ceramic infrared emitters are mounted at stainless steel reflectors which are used in the lower profile space of an extruded, anodized aluminum profile with an H-like cross-section. Aluminum cover profiles close the wiring space in the upper profile part and die-cast end pieces close the front sides.

The user simply and finally does the wiring, the attachment of the EBI elements to a profile steel frame created on-site and the connection to the electrical network.

Elstein EBF construction elements are available in five standard lengths and can be combined in order to form flat or curved radiation surfaces in any installation position.

HLS Rod Heater

Heaters of the Elstein HLS series are particularly suitable in plant construction, in which customer-specific special solutions are developed and for applications that require high performance.

Elstein HLS high-performance heaters are ceramic infrared rod emitters that can be used for operating temperatures of up to 1,000 °C and area outputs of up to 87 kW/m².

The HLS have a gold-plated ceramic parabolic reflector and emit up to 80 % of the energy used as infrared radiation to the material to be heated.

In this way, HLS emitters enable product temperatures of up to 700 °C or high throughput speeds. The typical operating temperature of 1,000 °C is reached in less than a minute.

Elstein HLS high-performance radiators are available in two designs with 750 W 230 V or for paired series connection with 375 W 115 V.

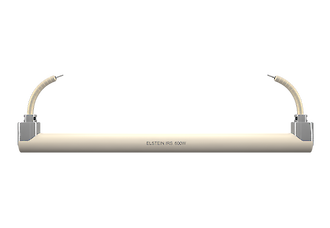

IRS Rod Heater

Due to the rod-shaped design, Elstein IRS ceramic emitters are ideally suited for linear heating tasks.

An example of linear heating tasks can be found in the wood industry, where IRS rod heaters are used to preheat edge strips.

IRS series heaters have one mounting socket on each side, with which they can be fixed to a mounting profile with fixing springs. They are designed for operating temperatures of up to 750 ° C. With the help of mounting profiles, area outputs of up to 72.0 kW/m² can be achieved.

Elstein IRS rod heaters are standardly available in two designs and cover the power range from 200 W to 600 W.

SBM Rod Heater

Elstein SBM rod heaters have been developed for use in infrared saunas and due to their long-wave infrared radiation gently and pleasantly warm the human body.

The rod heaters SBM can also be used for other heating tasks. Due to their long oval design, they are particularly suitable for linear heating or for space-saving installation when low installation heights have to be achieved.

Elements of the Elstein SBM series can be installed in any position.

Elstein SBM rod heaters enable area outputs of up to 36.0 kW/m² as standard and are available in two designs, which cover the output range from 200 W to 400 W.

Elstein EBF construction elements are available in five standard lengths and can be combined in order to form flat or curved radiation surfaces in any installation position.