Heat Torch™ 200

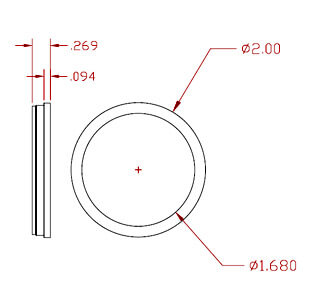

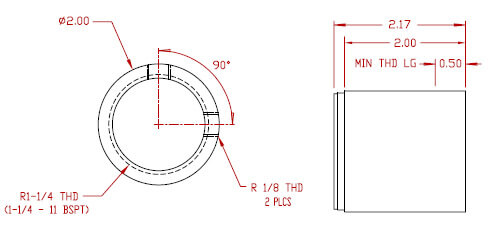

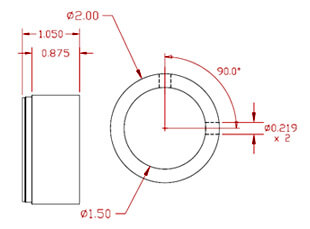

The Heat Torch™ 200 is engineered to satisfy the most demanding requirements. It is contained in a 2” diameter stainless steel pipe and is available in three sizes. The 5” long heater body is for power ratings from 1000 to 4250 watts (with power increments of 250 watts). The 9” long is for power ratings of 4500 to 8500 watts (with standard power increments of 500 watts). The 13” long heater is for power ratings from 9000 to 12000 watts (with standard power increments of 1000 watts).

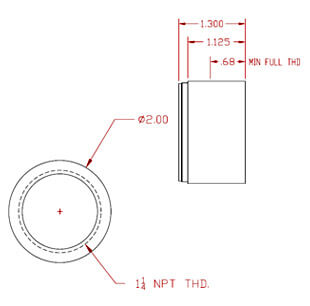

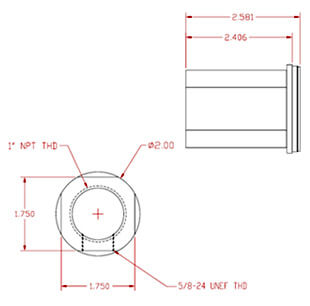

The Heat Torch™ 200 has an allowable compressed air flow ranging from 9.6 to 100 SCFM. The maximum air input temperature is 250°F (121°C) with 1300°F (704°C) the maximum output temperature. Standard inlet fitting is a 1” NPT female. Standard outlets are 1 1/4” female NPT fitting or no exhaust fitting.

This Heat Torch™ 200 service applications include high capacity staking, curing, drying, heat-shrinking, sterilization, adhesive activation, air scrubbing, semiconductor processes, wafer drying, and air knives. Designed to heat any non-combustible gas.

We provide pressure testing as an add-on service.

MAX WATT |

MAX INLET |

MAX EXHAUST |

MIN SCFM |

MAX SCFM |

PSIG* |

| 12500W | 250°F | 1300°F | 9.6 | 100 | 120 |

DRAWINGS (Step 3D File):

DRAWINGS (2D):

Mounting = Horizontal / Vertical

Leads = 12 Gauge, 12″ long

Heater Body = Stainless Steel

Air Entryway Fitting = Stainless Steel

Applications for the Heat Torch™ 200 include:

-

-

-

- High Capacity Staking

- Curing

- Drying

- Heat Shrinking

- Sterilization

- Adhesive Activation

- Air Scrubbing

- Air Knives

-

-

Additional Information:

airflow / pressure drop chart

| AIRFLOW (SCFM) | 500W-4250W PRESSURE DROP (PSIG) | 4500w-8500W PRESSURE DROP (PSIG) | 8750W-1250W PRESSURE DROP (PSIG) |

| 10 | 0.4 | 0.7 | 1.1 |

| 20 | 0.8 | 1.5 | 2.3 |

| 30 | 1.7 | 3.4 | 5.1 |

| 40 | 3.0 | 6.0 | 9.0 |

| 50 | 4.7 | 9.4 | 14 |

| 60 | 6.8 | 14 | 20 |

| 70 | 9.2 | 18 | 28 |

| 80 | 12 | 24 | 36 |

| 90 | 15 | 30 | 45 |

| 100 | 19 | 38 | 57 |

WATTAGE / MINIMUM FLOW CHART

| WATTAGE | MINIMUM FLOW REQUIRED AT MAX POWER INLET AIR TEMPERATURE 72°F (SCFM) |

| 1000 | 9.6 |

| 4000 | 9.6 |

| 5000 | 12.4 |

| 6000 | 14.8 |

| 7000 | 17.0 |

| 8000 | 19.3 |

| 9000 | 21.4 |

| 10000 | 23.5 |

| 11000 | 23.5 |

| 12500 | 28.4 |