RELAYS

SOLID STATE RELAYS

These units are rated for 5-100 amps with operational voltages up to 600 VAC single phase. This series is zero fired, high isolation > 50 meg ohms/500DC, or phase fired. The input signal can be 3-32 VDC, 15-60 VAC, 80-250 VAC, or 4-20mA.

These units are rated for 25-100 amps with operational voltages up to 600 VAC three-phase three leg switching. This series is zero or phase fired. The input signal can be 4-32 VDC, 250 VAC, or 4-20mA.

SCR POWER CONTROLLERS

EPS3-60-H(480 VAC) Digital Power Regulator (3-Pole)

Digital Power Controllers/Relay

Size: 7″ H (173mm) x 9″ D(229mm) x 3.75″ W (96mm)

EPS3-60-H(480 VAC) Digital Power Regulator (3-Pole)

Rated Current: 60 A Max

Main power supply: 280-550 VAC

Input: 4-20 mA, 1-5 V, 2-10 V, 0-5 V, 0-10 V, or VR10kOhms Field selectable

Phase Fired or Zero Crossover Switching Field Selectable

Operating Temperature: -20°C +80°C; 35-85% RH

Housing Material: Intensive PC + ABS (UL-94V0)

CE Certified; 110/220 VAC Auxiliary; Integral Fan & Fused

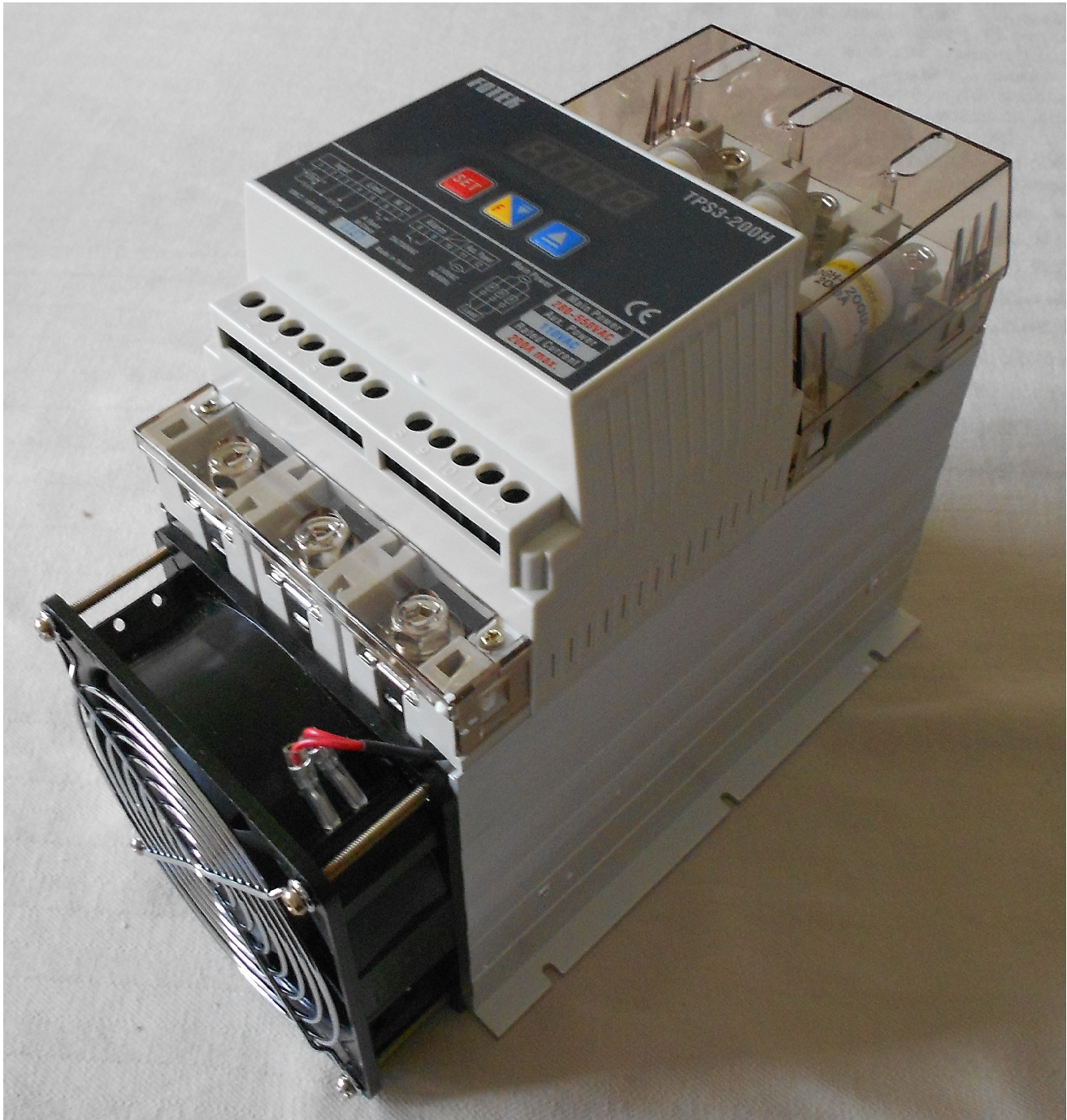

TPS3-200-H (480VAC) SCR Digital Power Regulator (3-Pole)

Heat Calculation: Current x 1.3 Watts x Phase = Wattage Generated by SCR’s

Size: 8.125″ H (210mm) x 10.25″ D(260mm) x 5.5″ W (140mm)

TPS3-200-H (480VAC) SCR Digital Power Regulator (3-Pole)

Rated Current: 200A Max

Main power supply: 280-550 VAC

Input: 4-20 mA, 0-20mA, 1-5V, 2-10V, 0-5V, 0-10V, or VR-10k Ohms Field selectable

Phase Fired or Zero Crossover Switching Field Selectable

Operating Temperature: -20°C +80°C; 35-85% RH

Housing Material: Intensive PC + ABS (UL-94V0)

CE Certified; 110 VAC Auxiliary; Integral Fan & Fused

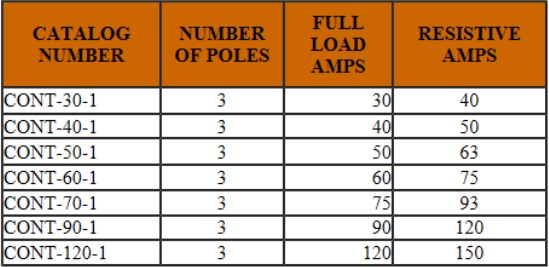

MECHANICAL RELAYS

- Magnetic Connectors

- NEMA 1 Enclosure Available

- 3 Pole with 120V holding coil-specify other coil rating

- Typical Cycling 3 times/minute