← Quartz Lamps & Heaters

Flat Panel Infrared Radiant Heaters

Ceramic Infrared Heaters→

Flat panel infrared radiant heaters are sleek and modern heating devices designed to efficiently emit infrared radiation for targeted heat. These heaters consist of thin, flat panel emitter surfaces that are typically made from materials like metal, carbon fiber, quartz, or ceramic that generate and emit infrared heat when electricity passes through them.

Characterized by their slim profile and versatile design, flat panel infrared radiant heaters are often wall-mounted or can be freestanding, allowing for easy installation and flexible placement in various spaces. They work by emitting infrared rays that directly heat up objects within their range without significantly warming the air, creating a comfortable and gentle warmth similar to the sun’s rays.

These heaters are favored for their energy efficiency, rapid heat distribution, and ability to provide focused heating in specific areas, making them suitable for both indoor and outdoor environments

PANEL MAX HEATERS

Designed to resist contamination, the PanelMAX1010 is ideal for use in screen printing, food warming and other low heat applications. The heater’s “sealed face” keeps contaminants away from the heating element, and this metal surface can be easily wiped or brushed clean whenever needed. The ruggest all-metal construction results in a shock-proof shatter-proof heater that is durable and long lasting. No fragile glass, ceramic or fiber is used.

The PanelMAX 1120 is a lightweight, yet sturdy and durable radiant heater panel. The emitter sheath is stainless steel with a black coating that makes it a highly efficient radiating surface. In additional the heaters low mass allows rapid start-up and fast response to controls. The patented PanelMAX hetaer features one inch (25mm) wide emitter strips that are individually replaceable for lower maintenance costs. Weighing only 5.5lbs the heater is easy to mount.

The PanelMAX 1330 is the only radiant heater that features specifally insulated heater emitter strips for higher performance. A unique compacted mineral insulation to electrically insulate the element wire, with a result of superior heat transfer and higher operating capabilities. Because of its rugged stainless steel construction, the PanelMAX 1330 will last longer. And this heater features a high emissivity black coating and a uniform, full surface heat source for better efficiency.

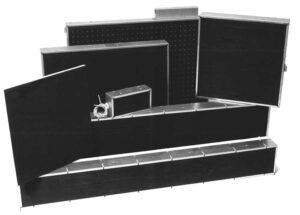

V Series Heaters

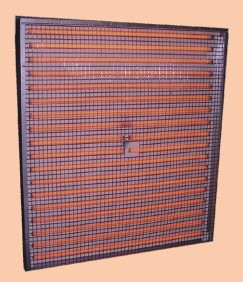

Q-SERIES PANEL HEATERS

Opaque quartz is the standard face on the Q-Series panel heaters. The properties of quartz make it a very efficient radiator of infrared energy. Double layer insulation is installed behind the insulating board to decrease back heat loss. Aluminized steel casings and welded stainless steel terminations are standard throughout the heater.

M & G SERIES PANEL HEATERS

The G-SERIES and M-SERIES line of IR panel heaters uses high temperature material as the radiant surface. All heaters provide uniform coverage with the convenience of a cleanable surface. Glass standard face on the G-Series panel heaters. The G-Series uses a high-temperature (1202°F/ 650°C, continuously operating temperature) black glass. The construction of the G-Series heater is similar to that of the F-Series heater, with the exception that glass replaces the quartz composite fabric as the face material. Metal is the standard face on the M-Series panel heaters. The face can be manufactured using either hard-coated aluminum or porcelanized steel. The remaining construction is exactly the same as that used in the G-Series heaters.

F Series

Downloads:

Guide books, information on processes and specific electric infrared heaters:

- A Simple Approach (PDF)

- Heat Processing Handbook for Paint & Powder (PDF)

- Infrared Muffle Heater (PDF)

- Quartz Tube (PDF)

- Panel Heaters Brochure (PDF)

- Products Thermoforming Retrofit Guidebook (PDF)

- V Series Brochure (PDF)

- V Series vs. the Competition (PDF)

- Thermoforming Case Study (PDF)

- IR Emitter Comparison (PDF)

FOR A RANGE OF INDUSTRIAL APPLICATIONS

- Thermoforming (sheet-fed, roll-fed, and rotary)

- Screen Printing (flash units and dryers)

- Electronics manufacturing (solder reflow and wave solder)

- Paint and powder coating applications

- Process manufacturing (paper, textile, and wood)

- Glass tempering and bending

- Automotive fiberglass production

- Wire, cable and tubing production

- Curing and drying

- Carpeting

- Foil

- Composites production